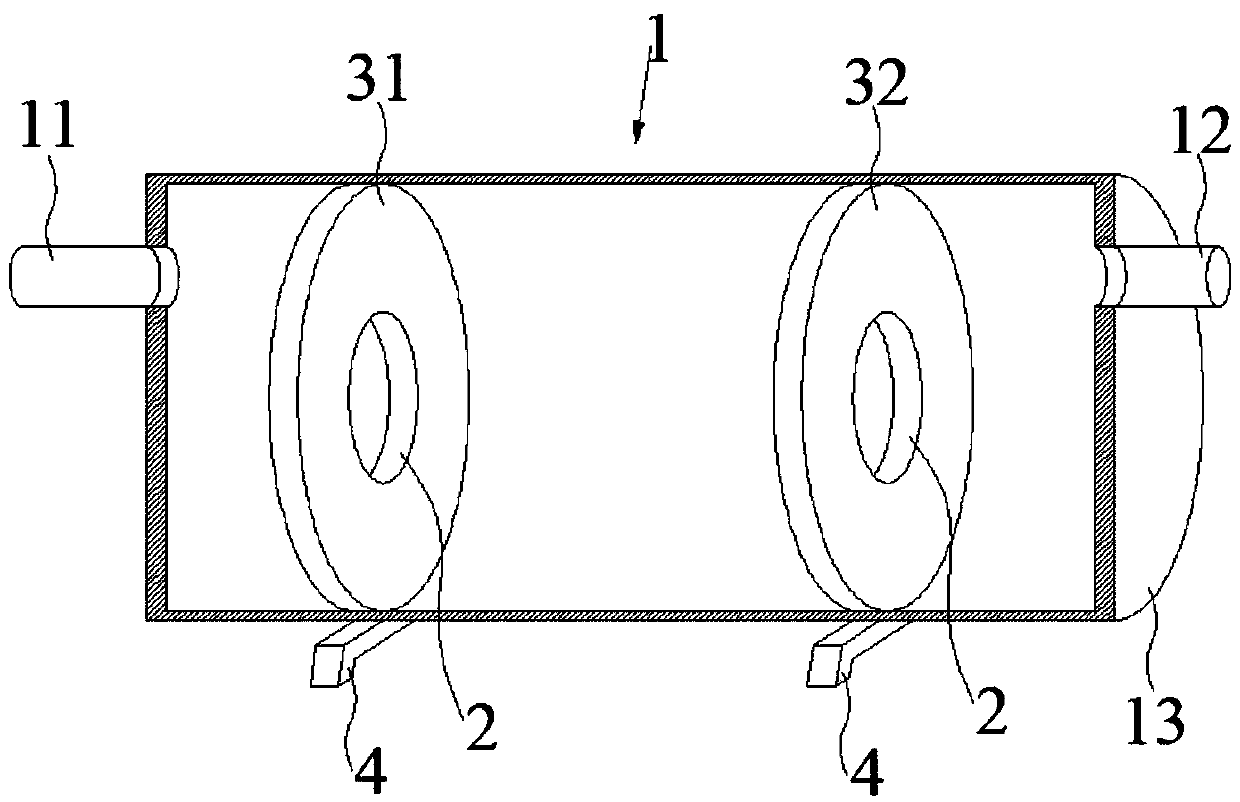

Liquid accumulator for compressor

A liquid accumulator and compressor technology, which is applied in the field of compressors, can solve problems such as abnormal vibration, excitation of the natural mode of the liquid accumulator, and noise generation, and achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As mentioned above, since the accumulator installed without clamps is directly fixed on the compressor, it is very easily affected by the vibration of the compressor, causing abnormal vibration of the accumulator and generating noise. After analysis, it is known that if the accumulator installed without clamps is used, the vibration generated during the operation of the compressor will be transmitted to the accumulator through the connected pipes and fixtures, and the natural mode of the accumulator will be excited, causing Abnormal vibration of the reservoir, resulting in noise. To solve this problem, the traditional method is to reduce the vibration amplitude and frequency of the liquid reservoir by reinforcing the outside of the liquid reservoir, but these methods are costly, complicated in structure, and the effect produced is not ideal. According to the analysis of the airflow characteristics in the liquid storage, the present invention proposes a method of setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com