Replacement method of coke oven column upper part cross-brace

A replacement method and a technology of horizontal tie rods, which are applied to coke oven parts, coke ovens, coke oven heating, etc., can solve the problems of coke oven pillar damage, low efficiency of furnace pillar braces, and inconvenient replacement of furnace pillars, etc. Achieve the effects of convenient production, safe and reliable engineering quality, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

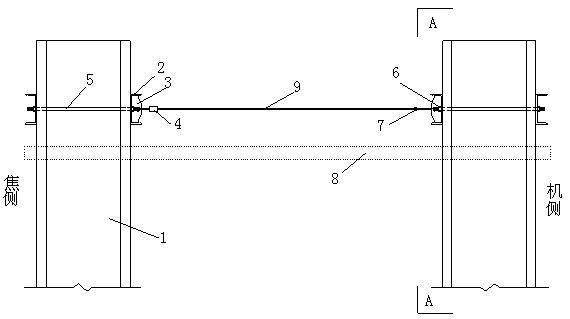

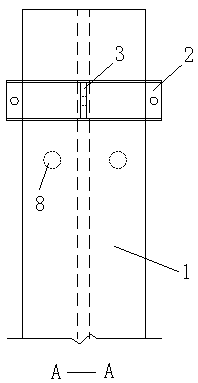

[0026] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the engineering state of using the splint device to tighten the machine side and the coke side furnace column of the coke oven according to the embodiment of the present invention, figure 2 for figure 1 Sectional view of A-A in Fig.

[0027] The method for replacing the upper horizontal brace of the coke oven column of the present invention comprises the following steps:

[0028] 1. The fixture 2 is made of channel steel, and the two sections of channel steel are connected by a screw 5, which is convenient for disassembly and reuse.

[0029] 2. An ear plate 3 is welded in the middle of the channel steel on the coke side furnace column close to the center line of the coke oven, which is used for the wire tensioner for temporarily tightening the furnace column.

[0030] 3. An ear plate is welded in the middle of the channel steel on the side of the machine side furnace column close to the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com