Preparation method for fiber reinforced concrete with uniformly-dispersed basalt fibers

A fiber-reinforced concrete and basalt fiber technology, which is applied in the field of building materials, can solve problems such as basalt fiber is not easy to disperse, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

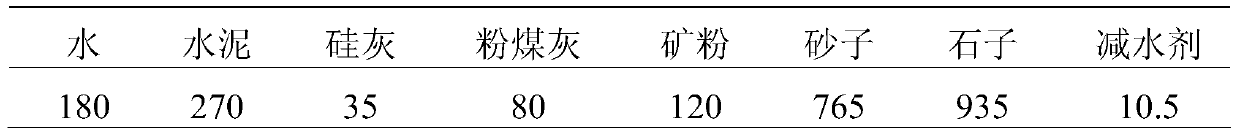

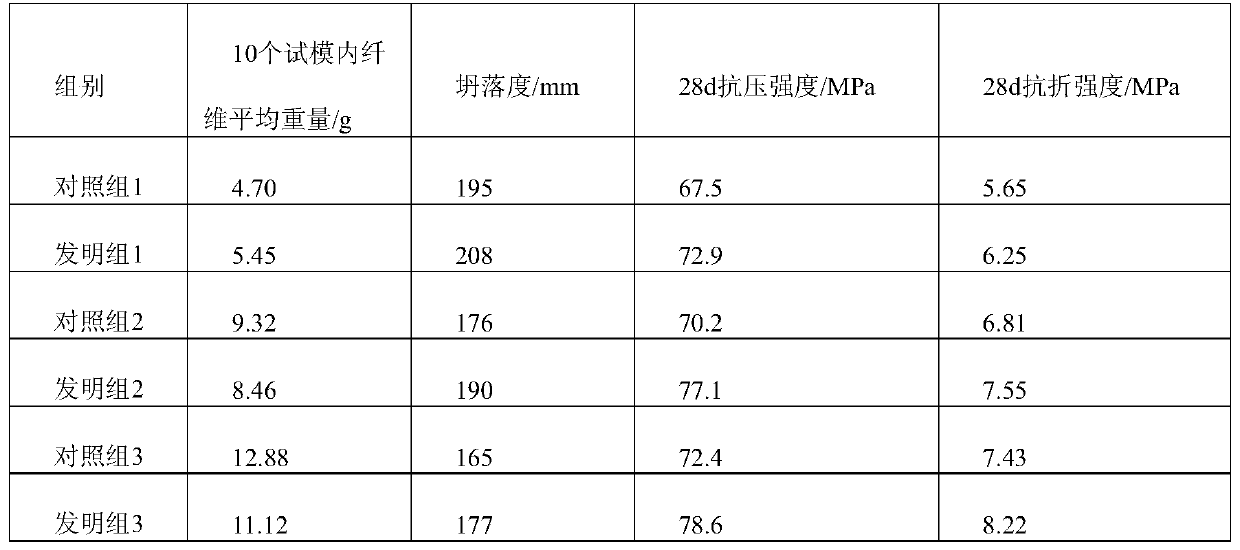

example 1

[0036] (1) Fiber dispersant concentration:

[0037] ①Concentration of fiber dispersant A: the concentration of 4-amino-1,2-catechol hydrochloride is 1g / L, and the concentration of trishydroxymethylaminomethane is 12g / L

[0038] ②Concentration of fiber dispersant B: the concentration of sodium chloroacetate is 12g / L, the concentration of sodium bicarbonate is 4g / L, and the concentration of dimethylformamide is 20g / L

[0039] (2) Basalt fiber length 12mm, dosage: 5.6kg

[0040] (3) The preparation process of fiber concrete to make basalt fiber evenly dispersed is as follows

[0041] ①Mix the dispersant A and the metered basalt fiber together for 3 minutes according to the mass ratio of 3:1; add water to clean the fiber after drying the solution, and then dry the water;

[0042] ②Mix the dispersant B and the basalt fiber obtained in step (1) according to the mass ratio of 4:1 and stir for 2 minutes, drain the solution, add water to clean the fiber, then drain the water, and tak...

example 2

[0049] (1) Fiber dispersant concentration:

[0050] ①Concentration of fiber dispersant 1: 4-amino-1,2-catechol hydrochloride concentration is 3g / L, trishydroxymethylaminomethane concentration is 10g / L

[0051] ②Concentration of fiber dispersant 2: the concentration of sodium chloroacetate is 13g / L, the concentration of sodium bicarbonate is 3g / L, and the concentration of dimethylformamide is 15g / L

[0052] (2) Basalt fiber length 12mm, dosage: 8.4kg

[0053] (3) The preparation process of fiber concrete with evenly dispersed basalt fibers is as follows

[0054] ①Mix the dispersant 1 and the metered basalt fiber together for 3 minutes according to the mass ratio of 5:1; after drying the solution, add water 4 times the weight of the fiber to clean the fiber, and then dry the water;

[0055] ②Mix the dispersant 2 and the basalt fiber obtained in step (1) according to the mass ratio of 2:1 and mix and stir for 2 minutes, drain the solution, add water to clean the fiber, then dra...

example 3

[0062] (1) Fiber dispersant concentration:

[0063] ①Concentration of fiber dispersant 1: 4-amino-1,2-catechol hydrochloride concentration is 2g / L, trishydroxymethylaminomethane concentration is 11g / L

[0064] ②Concentration of fiber dispersant 2: the concentration of sodium chloroacetate is 15g / L, the concentration of sodium bicarbonate is 5g / L, and the concentration of dimethylformamide is 17g / L

[0065] (2) Basalt fiber length 12mm, dosage: 11.2kg

[0066] (3) The preparation process of fiber concrete with evenly dispersed basalt fibers is as follows

[0067] ①Mix the dispersant 1 and the measured basalt fiber according to the mass ratio of 4:1 and stir for 3 minutes; add water to clean the fiber after drying the solution, and then dry the water;

[0068] ②Mix the dispersant 2 and the basalt fiber obtained in step (1) according to the mass ratio of 3:1 and stir for 2 minutes. After drying the solution, add water 5 times the weight of the fiber to clean the fiber, then dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com