Stacking grouping method and stacking grouping device

A technology of stacking and lateral position, applied in the field of stacking and grouping method and the field of stacking and grouping packaging mechanism, can solve the problem of difficulty in realizing the stacking structure, and achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0026] A kind of stacking grouping method mainly comprises the following steps:

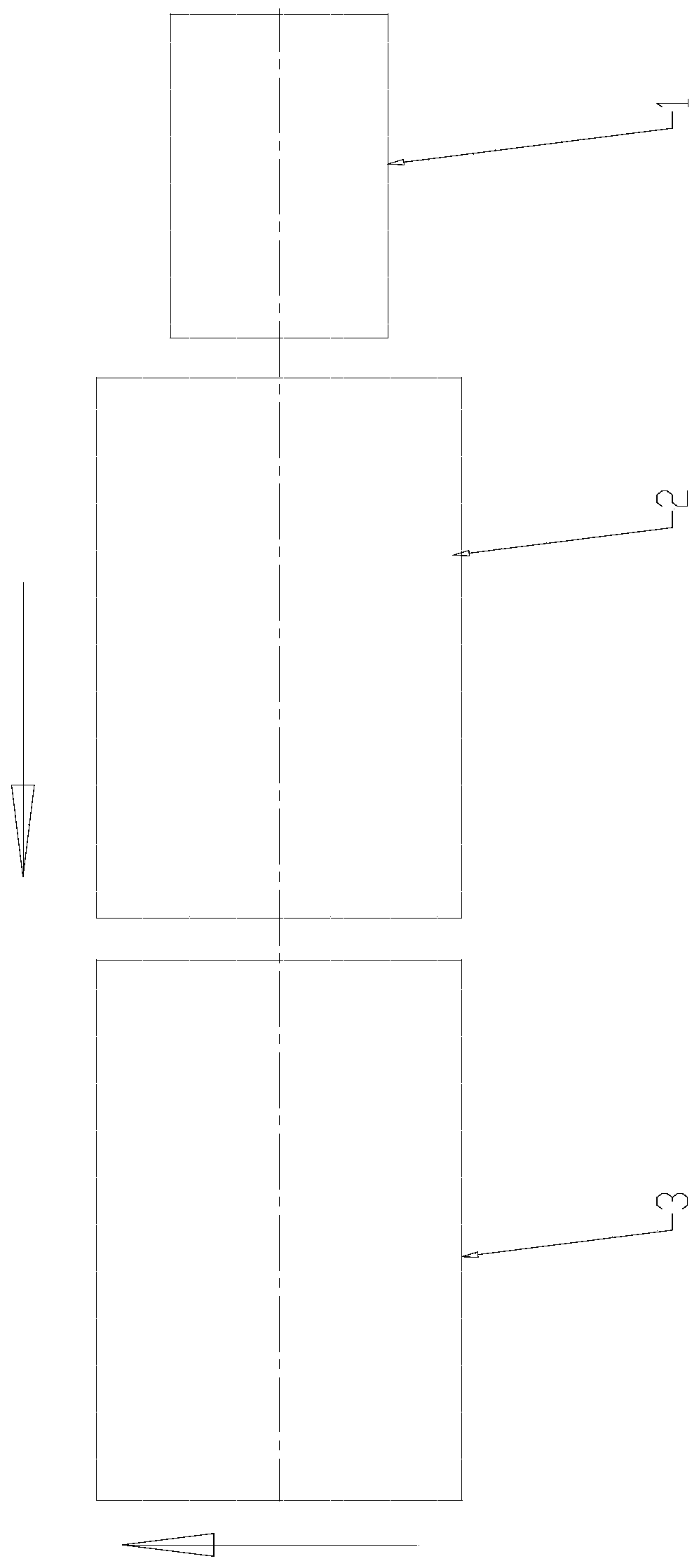

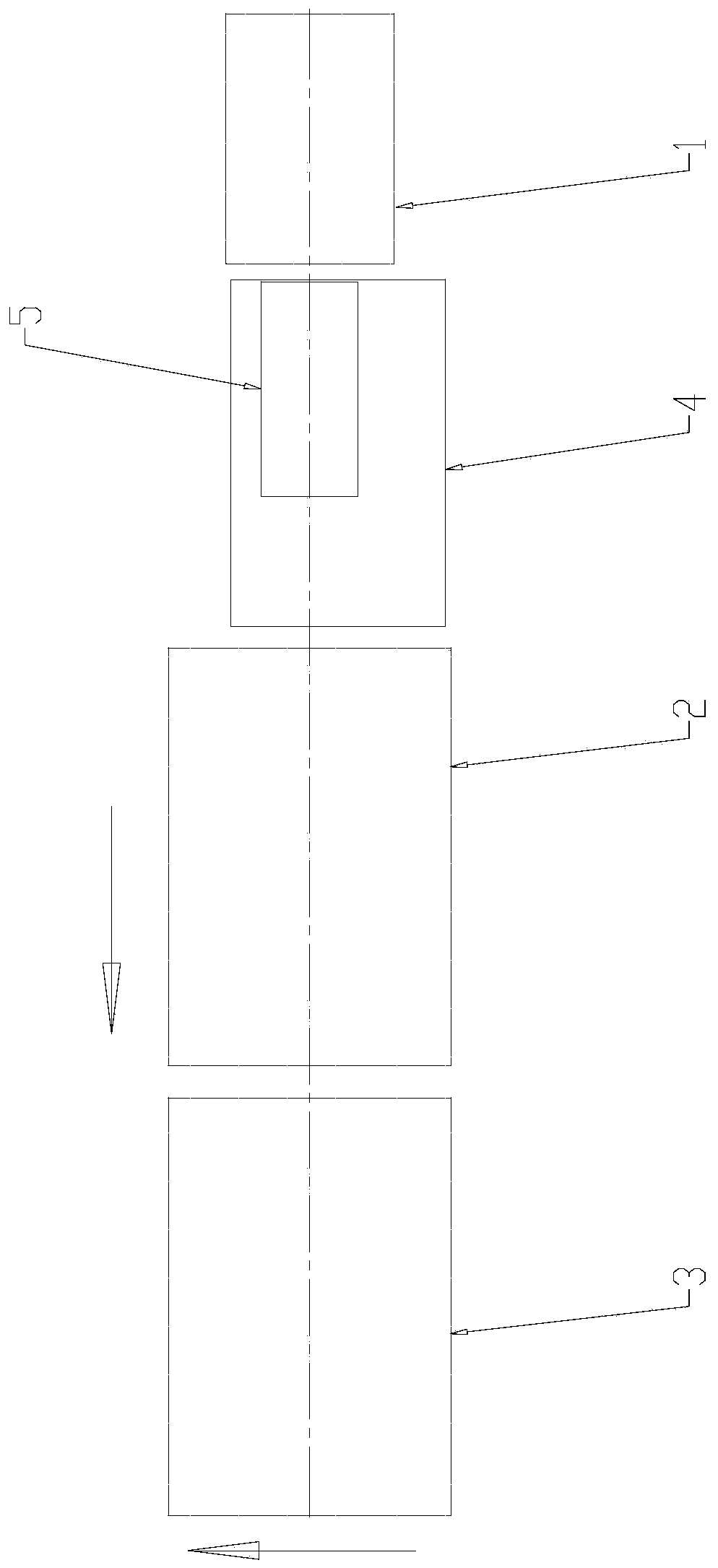

[0027] (1) Front conveying: Place several material bags forming a palletizing and grouping unit on the front conveyor 1 one by one, and transport them to the palletizing and grouping mechanism 4 one by one.

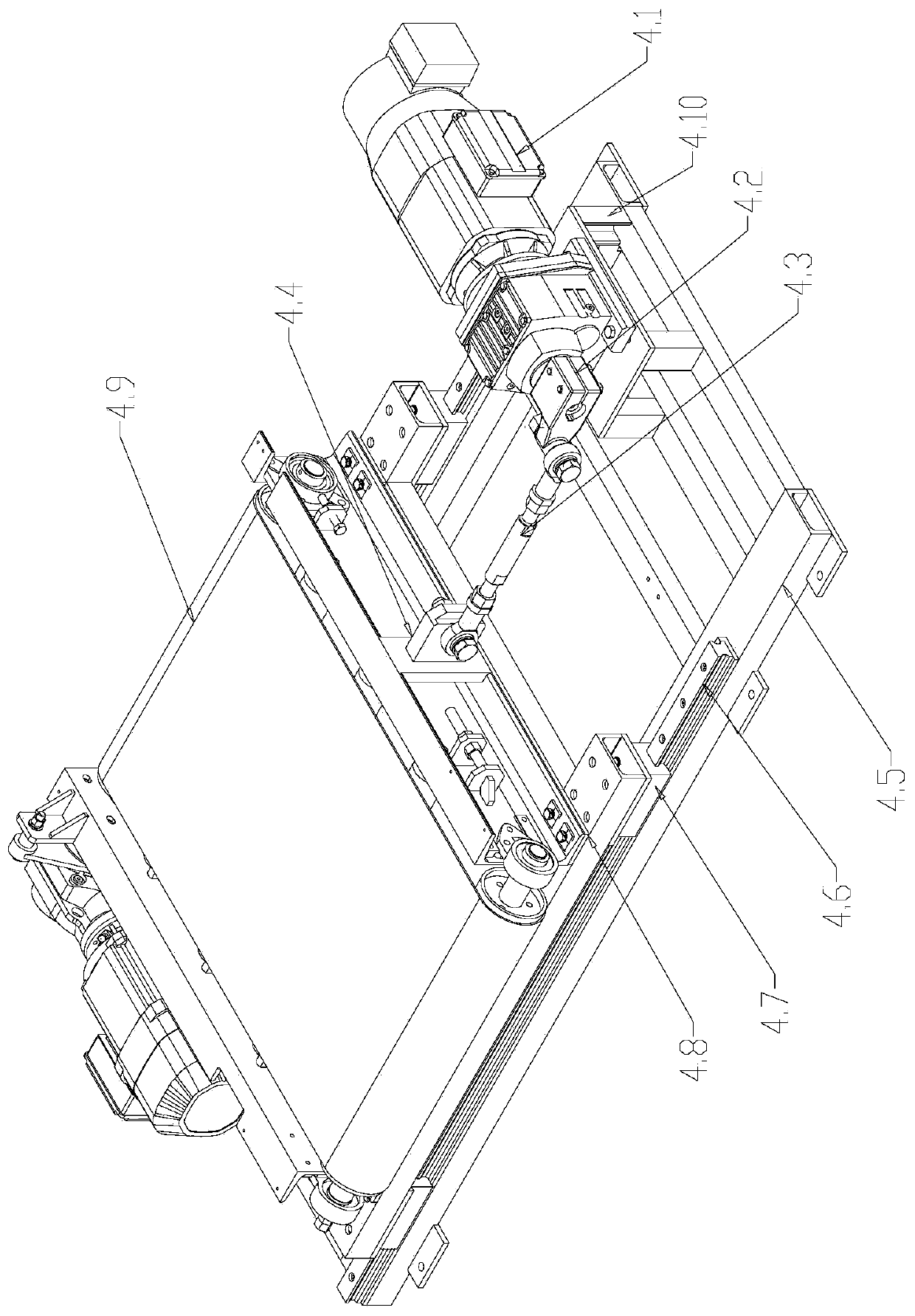

[0028] (2) Packing and conveying: Adjust the lateral position of each material bag in the palletizing and grouping unit through the palletizing and grouping mechanism 4 and transport the bags to the indexing conveyor 2 one by one, and the palletizing and grouping mechanism 4 It can drive the material bag to reciprocate laterally to adjust the lateral position of the material bag falling on the indexing conveyor 2, and transport the palletized and grouped material bag to the appropriate position on the indexing conveyor 2 according to the different palletizing and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com