Flexible pushing mechanism for sealing rings

A pusher mechanism and sealing ring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the work intensity of tooling management personnel, affecting product production efficiency, and poor error prevention effect, so as to shorten the zero replacement The effect of reducing mold time, reducing tooling and tooling management costs, and good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

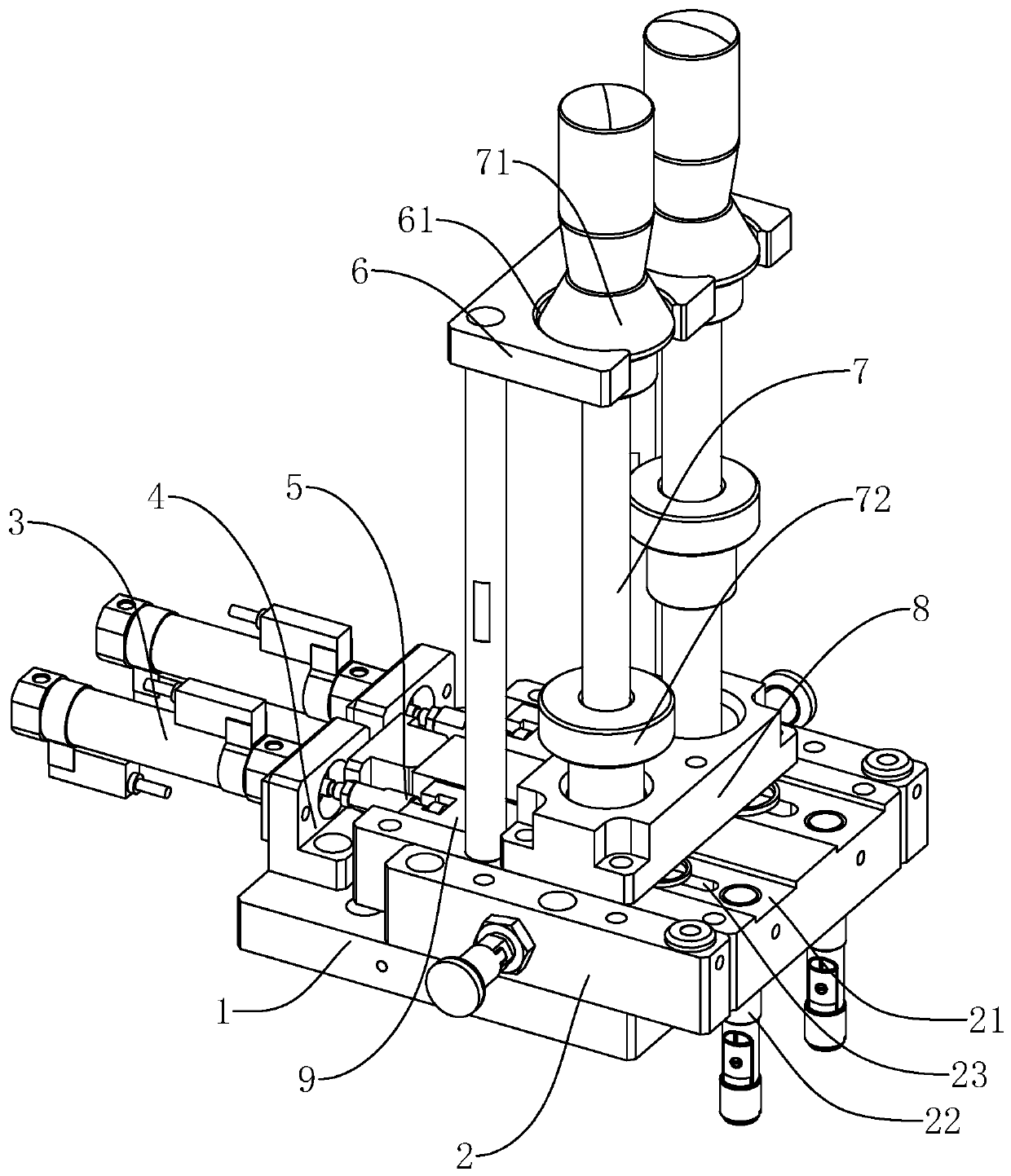

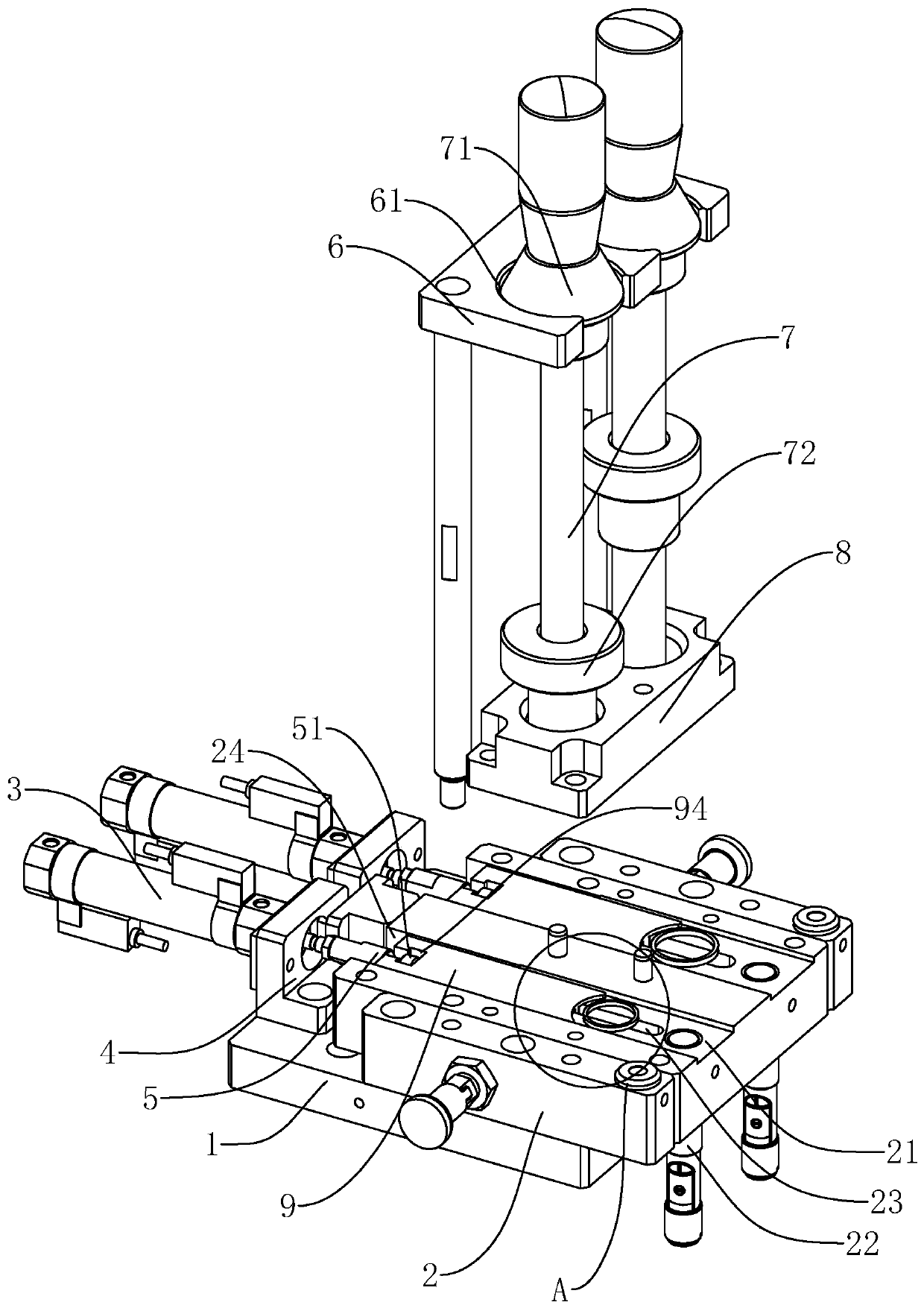

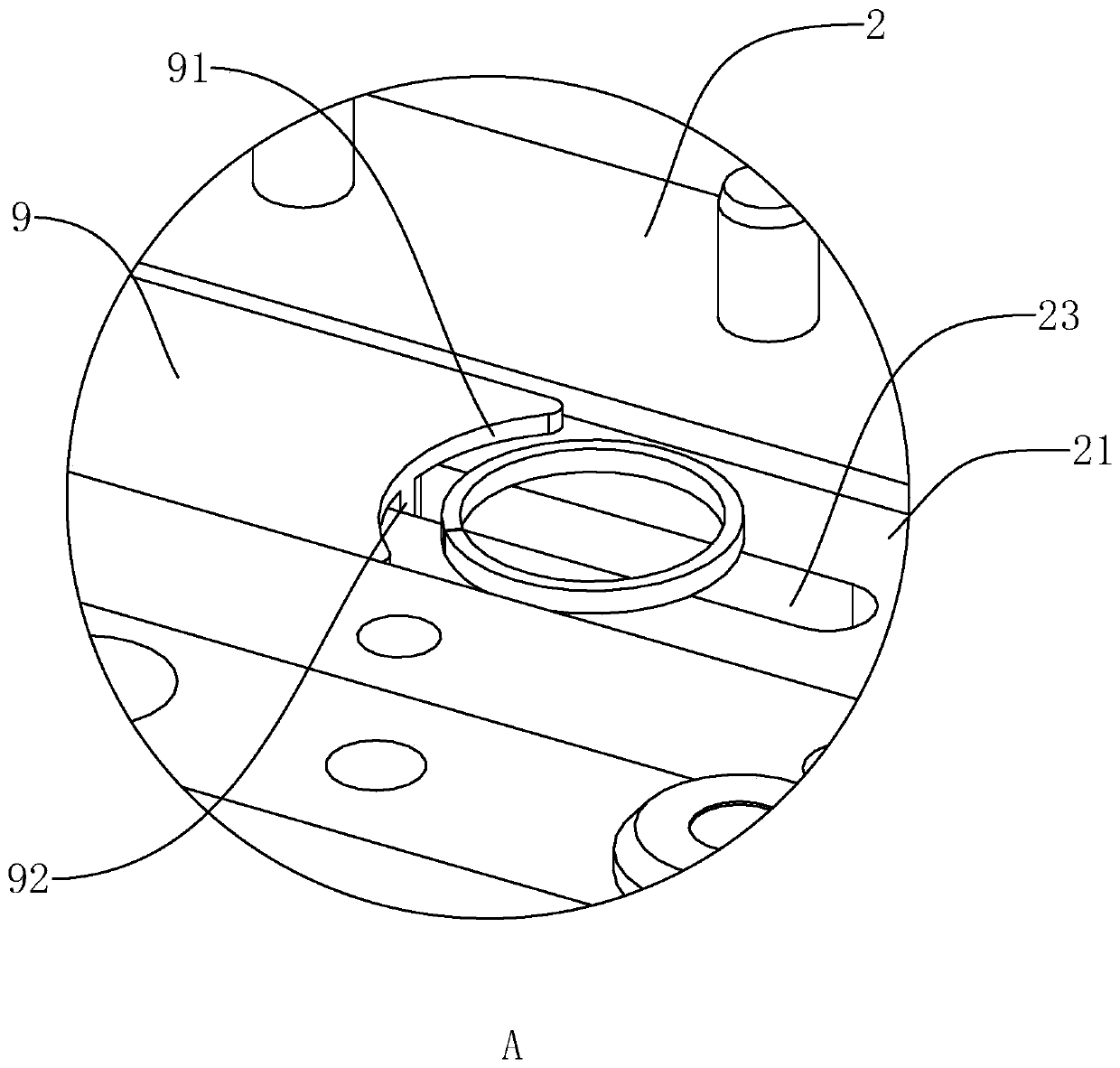

[0033] Such as figure 1 As shown, a sealing ring flexible pushing mechanism includes a fixed base 1 . A pushing seat 2 and a pushing cylinder 3 are arranged on the fixed base 1 . At the same time, a pushing block 9 for pushing the sealing ring is provided on the upper side of the pushing seat 2, and the pushing cylinder 3 is connected with the pushing block 9 and drives the pushing block 9 to reciprocate along the length direction of the pushing seat 2 and To achieve the role of pushing the sealing ring. The material storage support 6 is also arranged on the material pushing seat 2 . The material storage support 6 is provided with a material guide roller 7 for socketing a plurality of sealing rings, and the material guide roller 7 is inserted into the material storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com