A caliper and a method for controlling the starting point of a thread by using the caliper

A technology of starting point and thread, which is applied to control the starting point of large-pitch sawtooth thread, and in the field of snap gauges, can solve problems such as impossibility, difficulty in meeting machining accuracy requirements, and difficulty in finding the starting point of thread, so as to avoid measurement errors, The effect of improving the accuracy of measurement and the accuracy of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

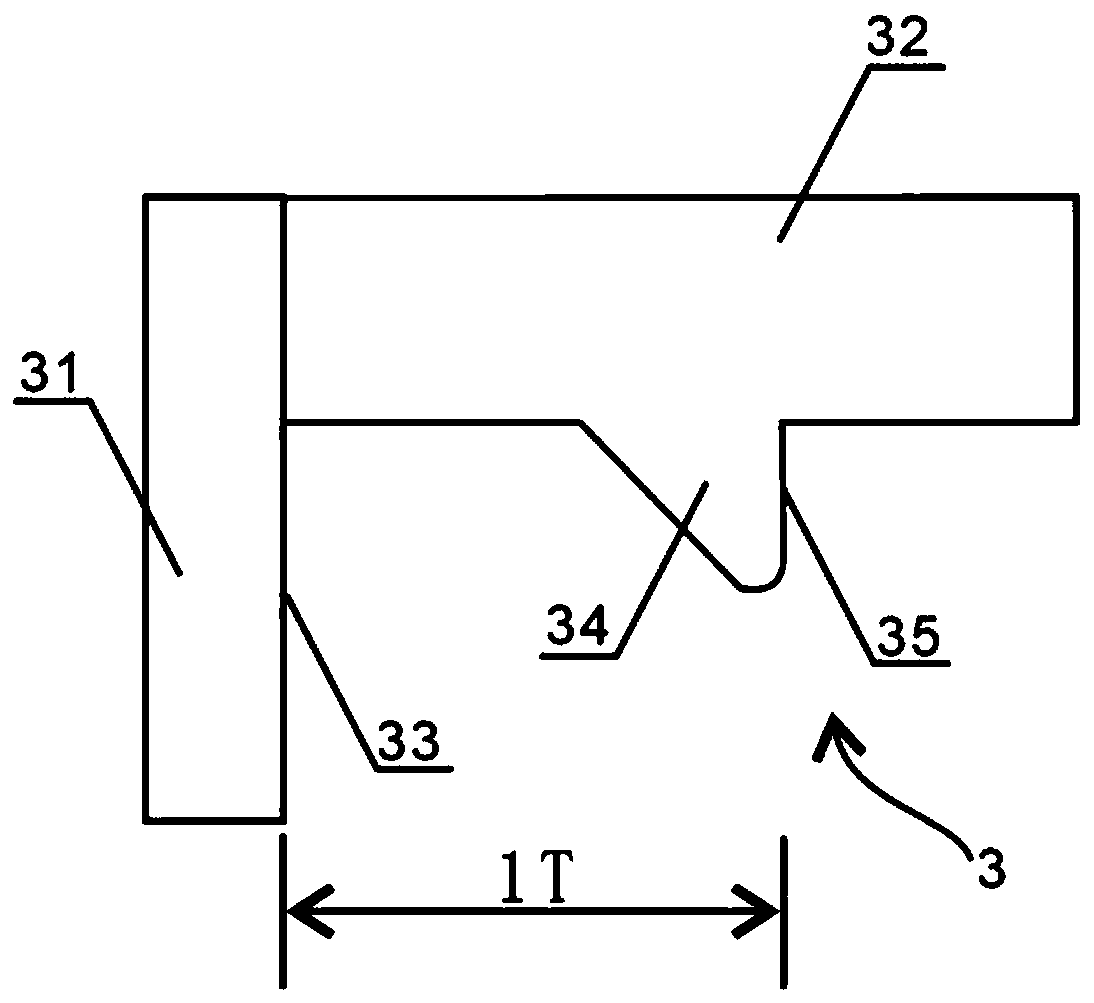

[0064] Such as Figure 2a , 2b As shown, in one embodiment of the present invention, the caliper 3 includes a first reference segment 31 and a second reference segment 32 arranged perpendicular to each other, and the side of the first reference segment 31 facing the second reference segment 32 is a measuring surface 33 , a screw saw 34 is set on the second reference section 32, the side of the screw saw 34 away from the first reference section 31 is a positioning surface 35, the positioning surface 35 is parallel to the measuring surface 33, and the distance between the positioning surface 35 and the measuring surface 33 The spacing is one pitch.

[0065] Utilize the caliper 3 described in the present embodiment, can obtain the method for controlling the starting point of the thread, the following example wherein with a kind of specific implementation method, this method comprises the following steps:

[0066] 1) In the thread roughing stage and before performance heat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com