A clamping and conveying mechanism of a green onion harvester

A clamping conveying and harvesting machine technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of loose clamping, damage to green onions, and failure to achieve the effect of clamping and conveying, so as to facilitate collection and reduce The effect of small damage and good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

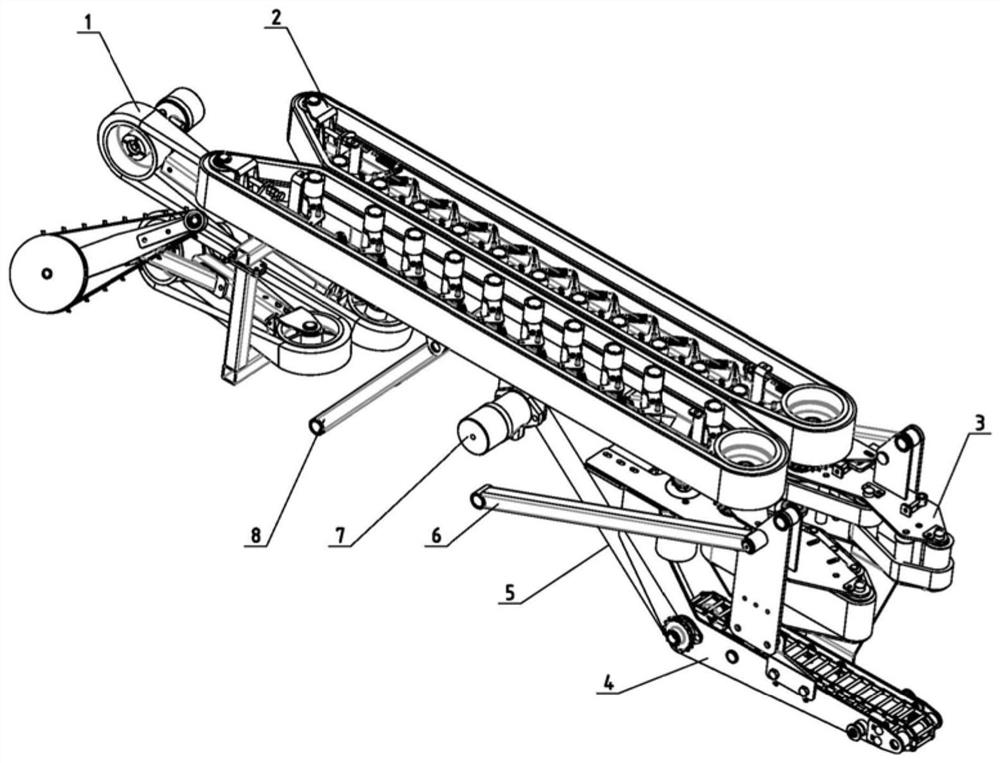

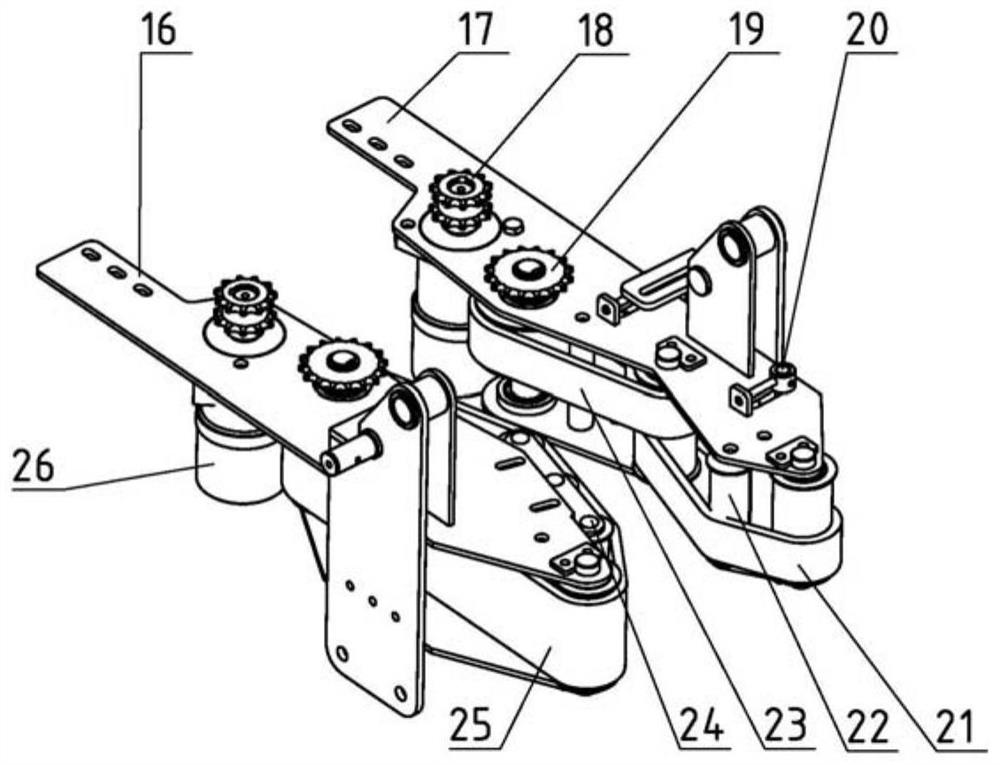

[0042] Attached below figure 1- attached Image 6 Further description will be made on the clamping and conveying mechanism disclosed in this embodiment;

[0043] Refer to attached figure 1 As shown, the clamping and conveying mechanism of the green onion harvester mainly includes a bottom conveying device 4, a primary clamping and conveying device 3, a secondary clamping and conveying device 2 and a green onion guiding device 1, and the whole structure passes through the front connecting rod 6 and the rear connecting rod. 8 connected to the host;

[0044] The clamping and conveying mechanism of the present disclosure can cooperate with the excavating device when in use. The bottom conveying device 4 penetrates into the excavating device and connects with the excavating shovel, and conveys the green onions and wrapped soil dug up by the excavating shovel upward from the bottom. The bottom conveying device 4 The rear connecting piece 9 and the front connecting piece 11 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com