Combined precision seeder based on principle of built-in feeding

A combined, seeder technology, applied in the agricultural field, can solve the problems that the survival rate and growth rate of seedlings cannot be well presented, the seeder cannot achieve precise quantitative control, and cannot absorb enough nutrients, etc., so as to improve nutrition. Absorb, prevent influence, prevent clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

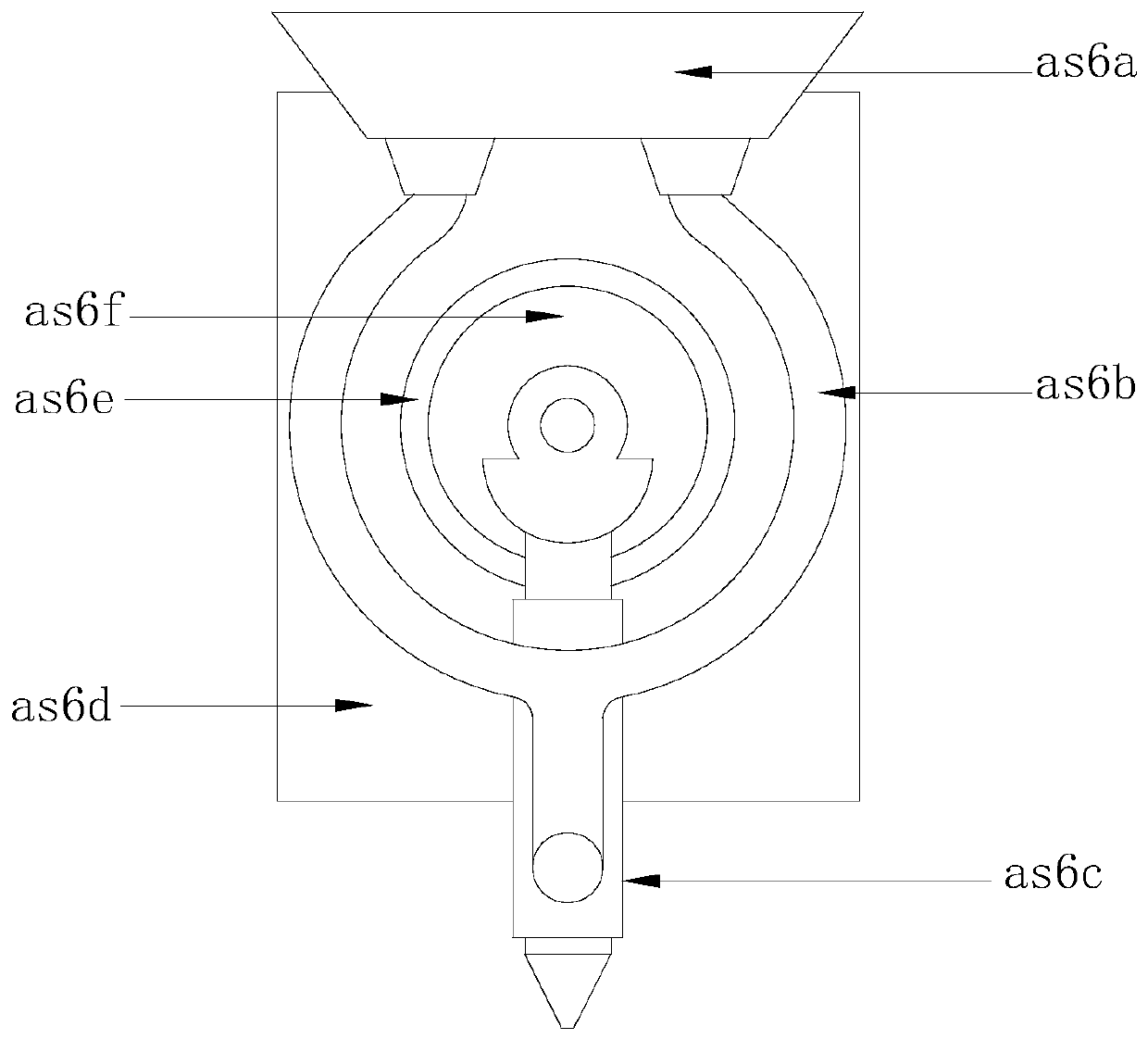

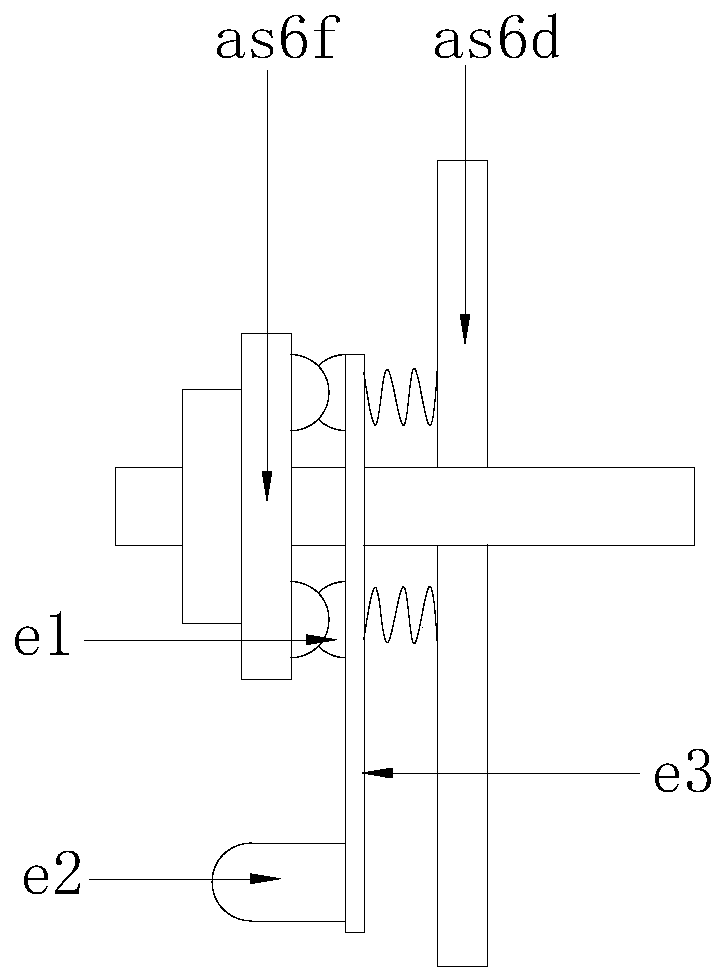

[0029] see Figure 1-Figure 6 , the present invention provides a combined precision seeder based on the principle of built-in material shifting, its structure includes an assembly main body as1, a storage box as2, a fixed frame as3, a driving motor as4, a scarifier as5, a seeding mechanism as6, and a driving wheel as7 , the drive motor as4 is provided with four, and the rear end is evenly and equidistantly distributed on the front end of the fixed frame as3 through a buckling method, and the two ends of the fixed frame as3 are connected with the two ends of the bottom of the assembled main body as1 through a fitting method, so The upper end of the seeding mechanism as6 is respectively installed on the bottom of the drive motor as4 by buckling. The sowing mechanism as6 is connected with the material storage box as2, and the lower end of one side of the material storage box as2 is respectively connected with the side of the drive motor as4, and the main body as1 is spliced and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com