Moving unit, plug connector component and LED module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The invention relates to a mobile unit for contacting plug connectors of LED modules. Furthermore, the invention relates to a plug connector assembly and an LED module.

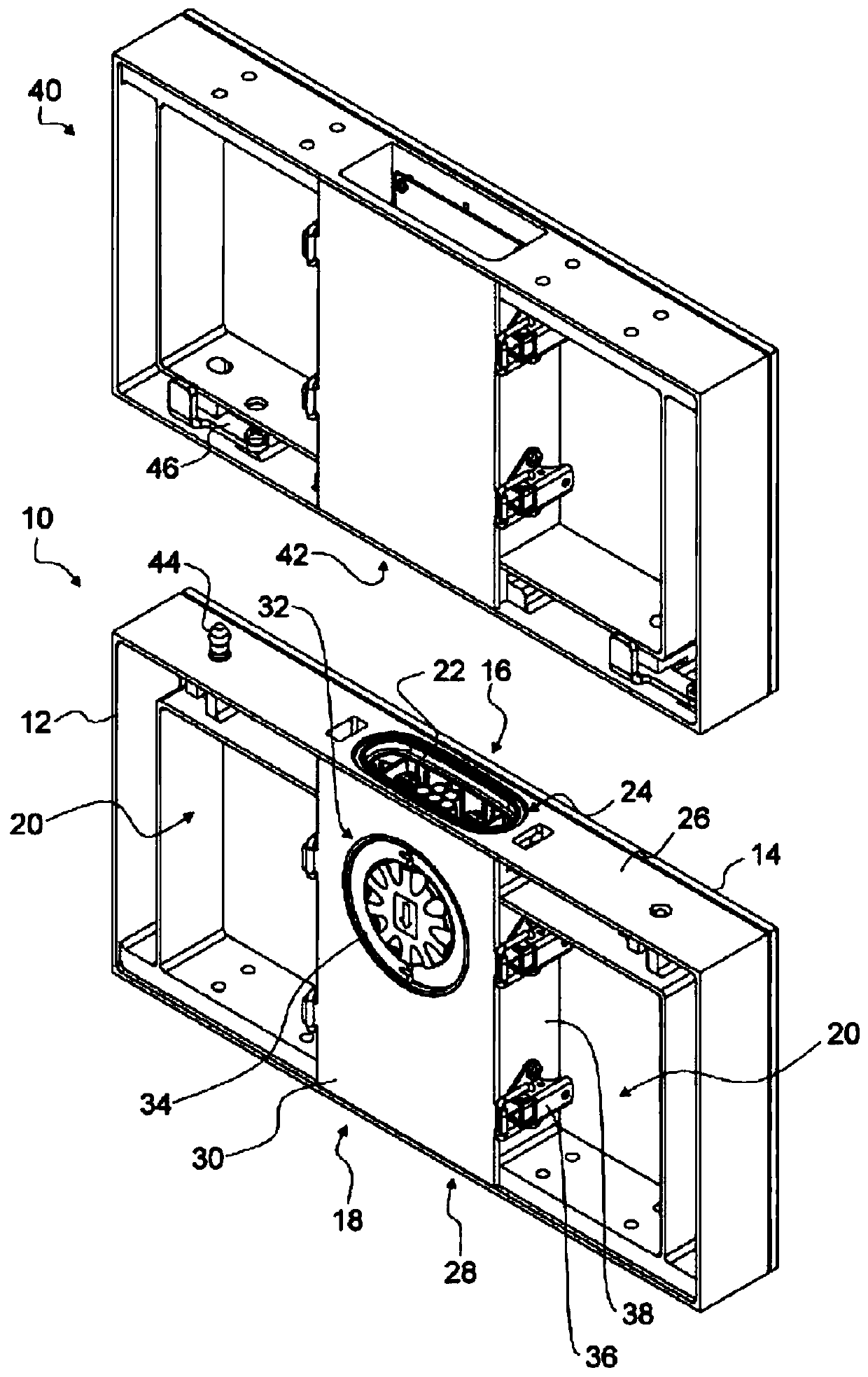

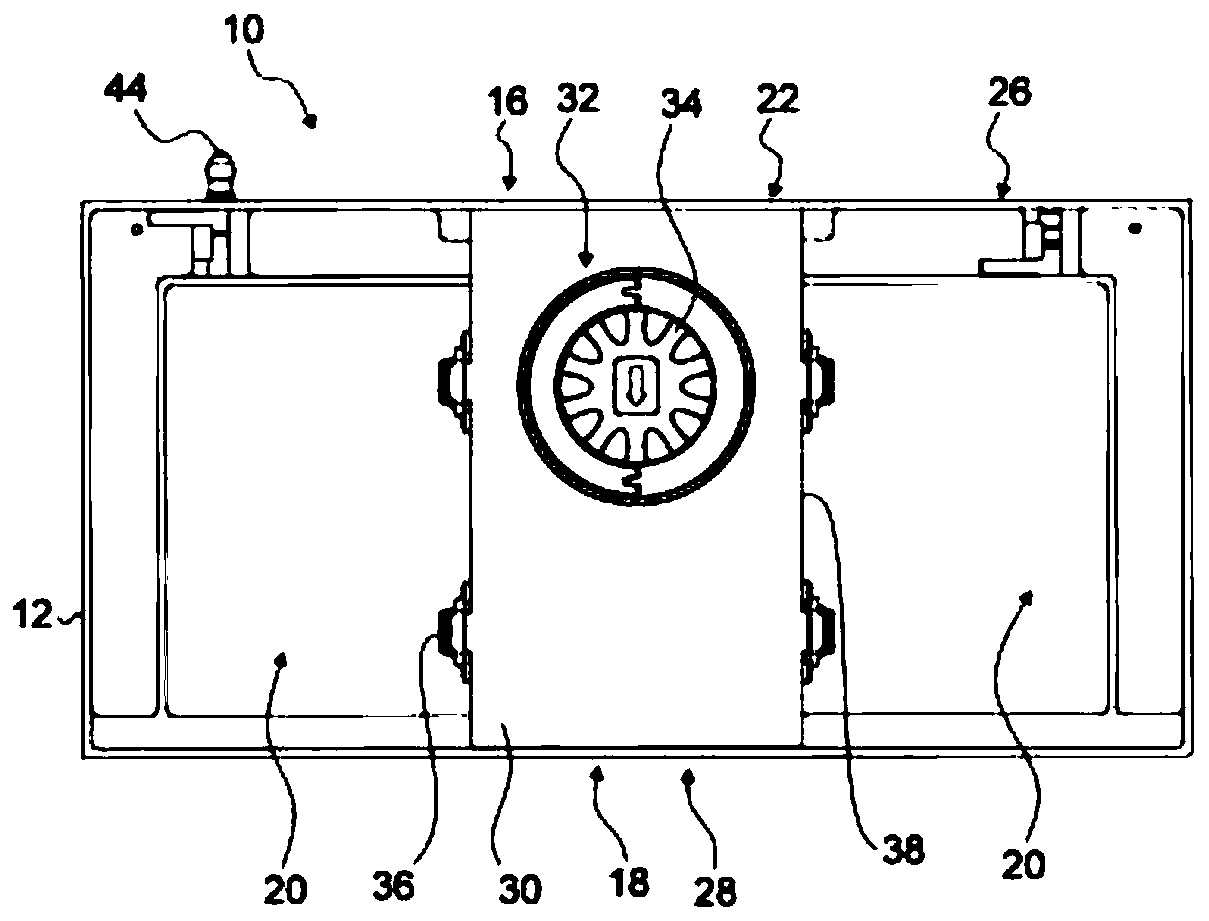

[0096] exist figure 1 An LED module 10 according to the invention is shown in , which has a holding frame 12 on which at least one LED panel 14 is arranged. For greater clarity (for drawing reasons), the LED module 10 is only shown at half height.

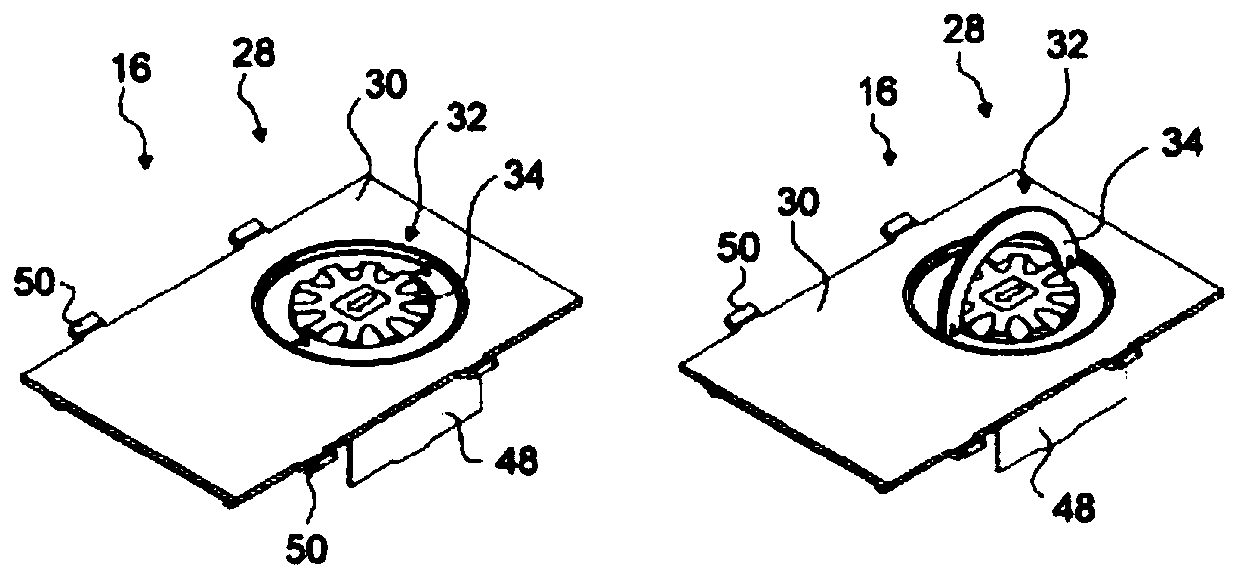

[0097] Furthermore, the LED module 10 comprises a plug-in connector assembly 16 which is accommodated at least partially in a receiving region 18 of the holding frame 12 , which is substantially U-shaped or pot-shaped.

[0098] The receiving area 18 is arranged centrally on the holding frame 12 , wherein a window-like free space 20 is provided on the sides, through which an operator of the LED module 10 can access the LED panel 14 .

[0099] The LED panel 14 can be fixed (electrically) magnetically on the holding frame 12 .

[0100] For example, four LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com