A plug-in sealed shield segment

A shield segment and sealing technology, which is applied in the field of plug-in sealed shield segments, can solve the problems of low water pressure and poor joint sealing, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

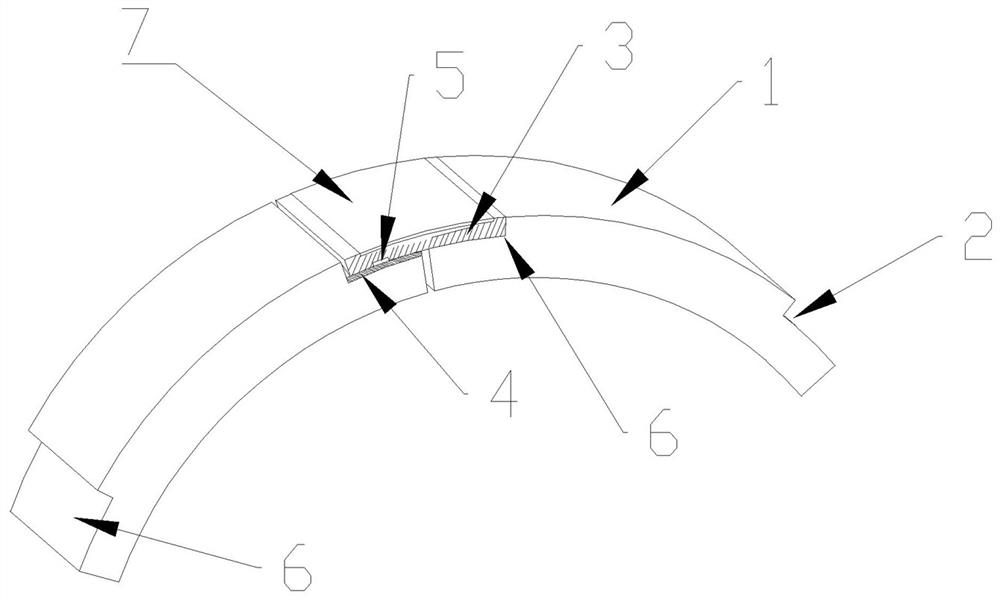

[0026] Such as figure 1 As shown, a plug-in sealed shield segment includes an arc-shaped segment body 1, and a first installation groove 6 and a second installation groove 2 are respectively provided on both sides above the segment body 1. The first installation groove 6 and the second installation groove 2 have an "L" shape structure with the opening facing outward; in the first installation groove 6, an extension rubber plate 3 is adhered by glue, and in the second installation groove 2 A small rubber plate 4 is stuck with glue; the outer side of the extended rubber plate 3 is located outside the segment body 1; the depth of the first installation groove 6 is greater than that of the second installation groove 2, and the first installation groove 6 The depth difference between the first installation groove 6 and the second installation groove 2 is equal to the thickness of the small rubber plate 4 ; the extensible rubber plate 3 is rectangular, and its thickness is equal to ...

Embodiment 2

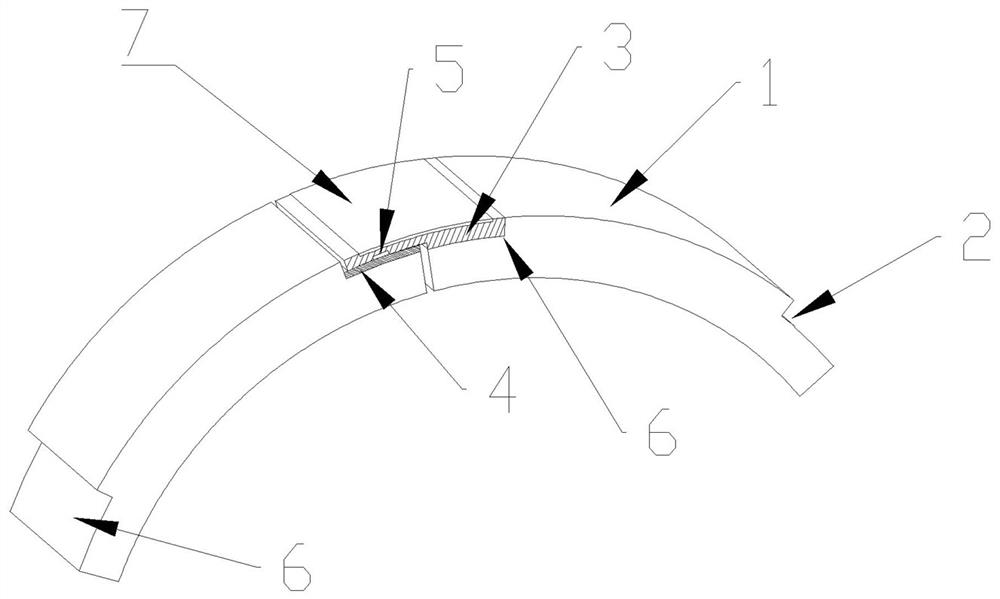

[0030] Such as figure 2 As shown, a plug-in sealed shield segment includes an arc-shaped segment body 1, and a first installation groove 6 and a second installation groove 2 are respectively provided on both sides above the segment body 1. The first installation groove 6 and the second installation groove 2 have an "L" shape structure with the opening facing outward; in the first installation groove 6, an extension rubber plate 3 is adhered by glue, and in the second installation groove 2 A small rubber plate 4 is adhered by glue; the outer side of the extended rubber plate 3 is located outside the segment body 1 .

[0031] The extended rubber plate 3 includes a fixed plate fixed in the first installation groove 6 and an extension plate located outside the segment body 1, and the sum of the thickness of the extension plate and the small rubber plate 4 is equal to the second installation groove 6. The depth of the groove 2 and the thickness of the fixing plate are equal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com