Fully-polished glaze ceramic tiles with granular flashing decoration and preparation method thereof

A full-glazed, granular technology, which is applied in the field of architectural ceramics production, can solve the problems of poor decorative effects, instability, and weakened flashing effects, and achieve high granular reflective effects and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

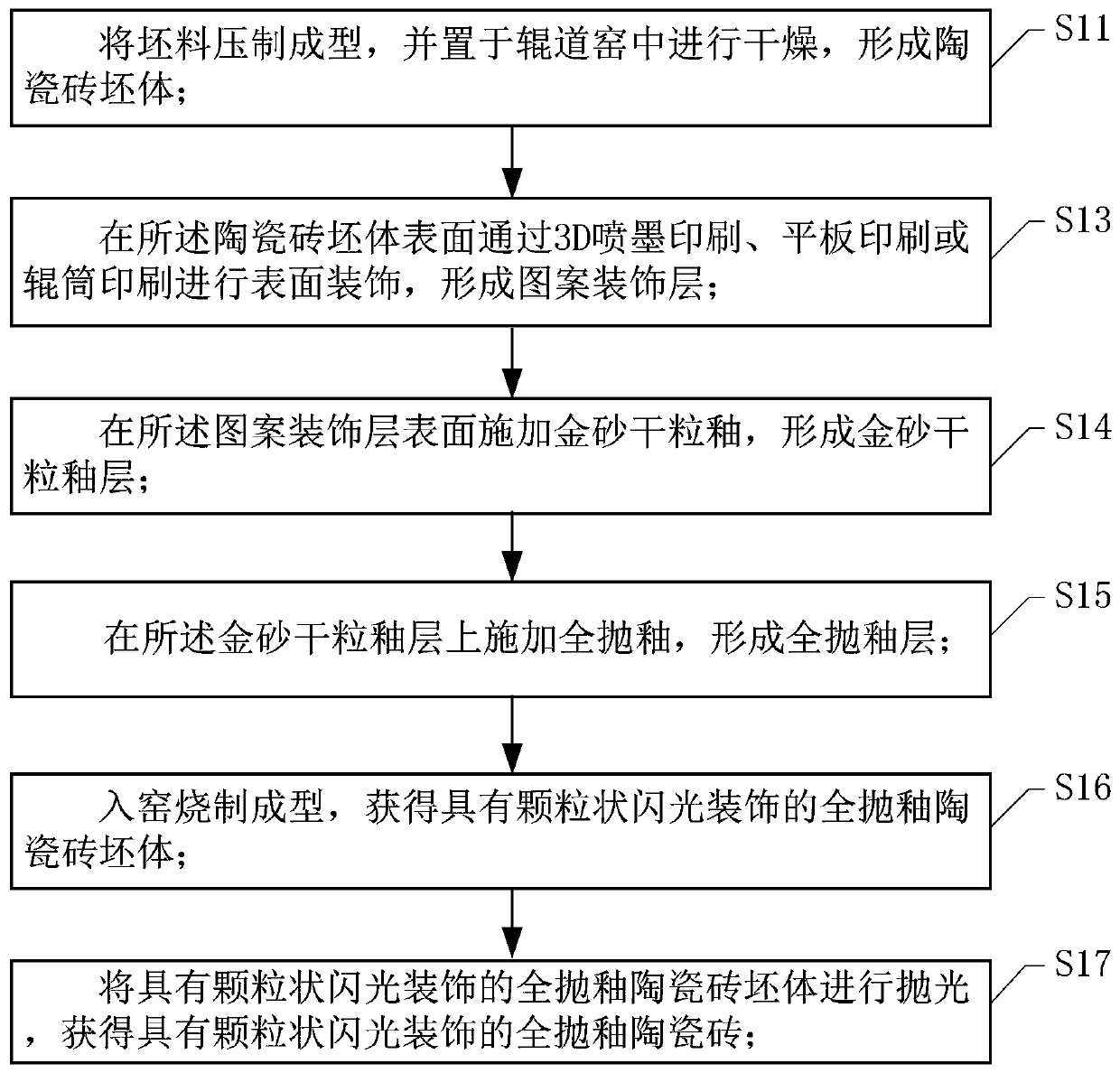

[0104] A preparation method of fully polished glazed ceramic tiles with granular flash decoration, which comprises:

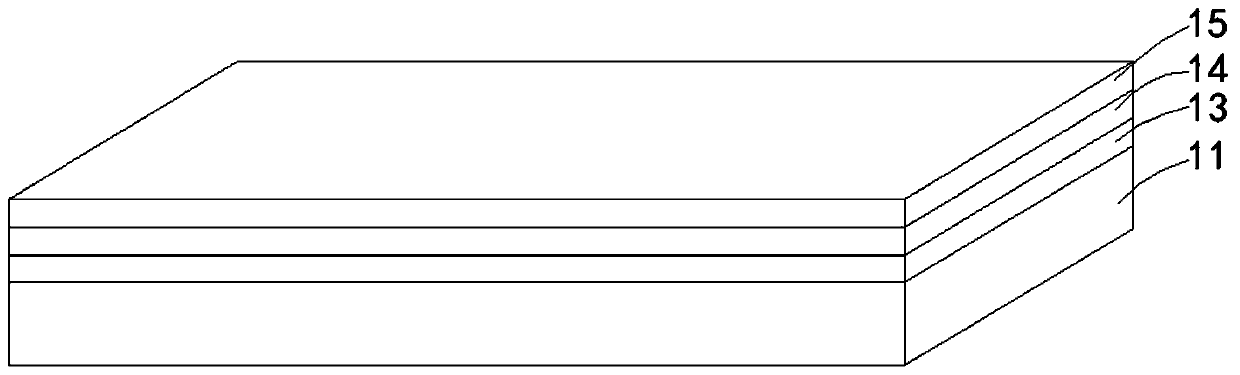

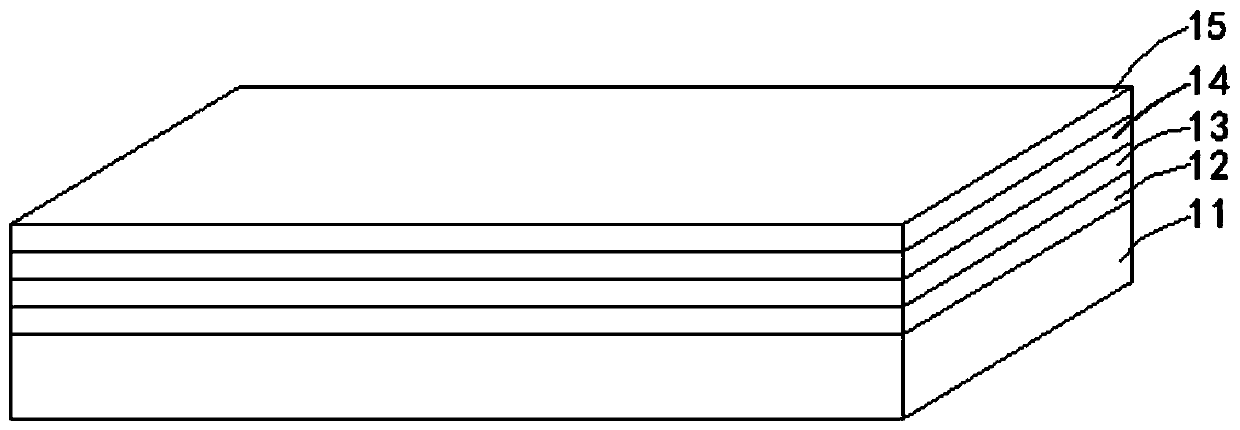

[0105] Step S11, pressing the blank into a shape, and placing it in a roller kiln for drying to form a ceramic tile body;

[0106] Step S13, performing surface decoration on the surface of the ceramic tile body by 3D inkjet printing, flat printing or roller printing to form a patterned decoration layer;

[0107] Step S14, applying gold sand dry glaze on the surface of the pattern decoration layer to form a gold sand dry glaze layer;

[0108] Step S15, applying a fully polished glaze on the gold sand dry grain glaze layer to form a fully polished glaze layer;

[0109] Step S16, firing into a kiln for molding to obtain a fully glazed ceramic tile body with granular flash decoration.

[0110] Step S17, polishing the fully polished glazed ceramic tile body with granular flash decoration to obtain a fully polished glazed ceramic tile with granular flash decoration;

[0111] Whe...

Embodiment 2

[0125] The difference between this embodiment and the first embodiment above is:

[0126] The gold sand dry grain glaze in the step D is applied on the pattern decoration layer through the glaze dotting process to form a gold sand dry grain glaze layer;

[0127] The composition of the golden sand dry grain glaze is calculated by weight percentage, including: transparent glaze slurry 65-95%, dry grain glaze 5-30%, ball earth glaze slurry 0-10%;

[0128] The specific gravity of the golden sand dry glaze is 1.20 to 1.70;

[0129] The viscosity of the glaze slurry of the golden sand dry glaze is 12-30s measured with a Markov funnel;

[0130] The glaze application amount of the golden sand dry glaze is 40-160g / m 2 ;

[0131] The composition of the ball soil glaze slurry is calculated in parts by weight, including: 100 parts of ball soil and 40-60 parts of water.

Embodiment 3

[0133] The difference between this embodiment and the first embodiment above is:

[0134] The gold sand dry grain glaze in the step D is applied on the pattern decoration layer through a spray glaze process to form a gold sand dry grain glaze layer;

[0135] The composition of the golden sand dry grain glaze is calculated by weight percentage, including: transparent glaze slurry 65-95%, dry grain glaze 5-30%, ball earth glaze slurry 0-10%;

[0136] The specific gravity of the golden sand dry glaze is 1.20 to 1.70;

[0137] The viscosity of the glaze slurry of the golden sand dry glaze is 12-30s measured with a Markov funnel;

[0138] The glaze application amount of the golden sand dry glaze is 40-160g / m 2 ;

[0139] The composition of the ball soil glaze slurry is calculated in parts by weight, including: 100 parts of ball soil and 40-60 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com