An automatic conveying material rack for small parts of automobile welding line

A technology for welding lines and small parts, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of lack of personal safety of operators, inability to meet the requirements of automatic production lines, and high labor intensity of employees. The effect of equipment utilization, saving equipment costs and energy consumption, and reducing business operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

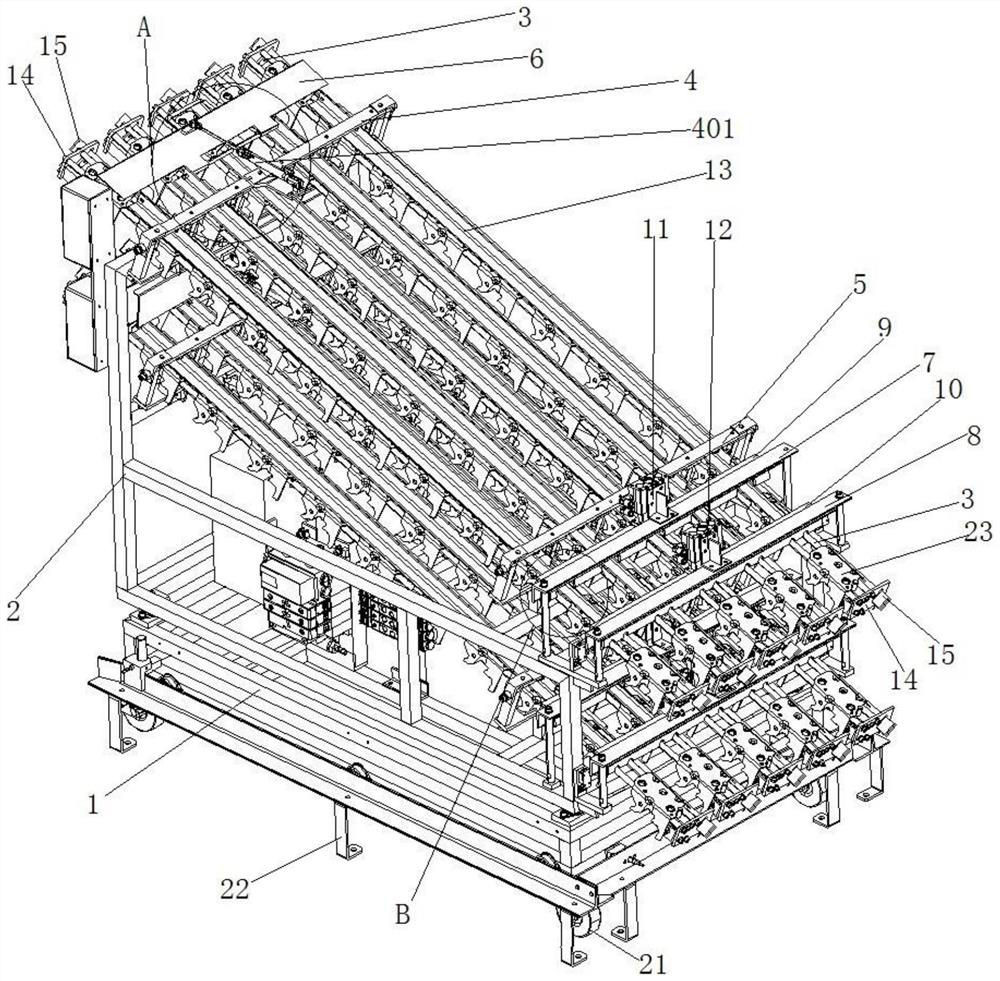

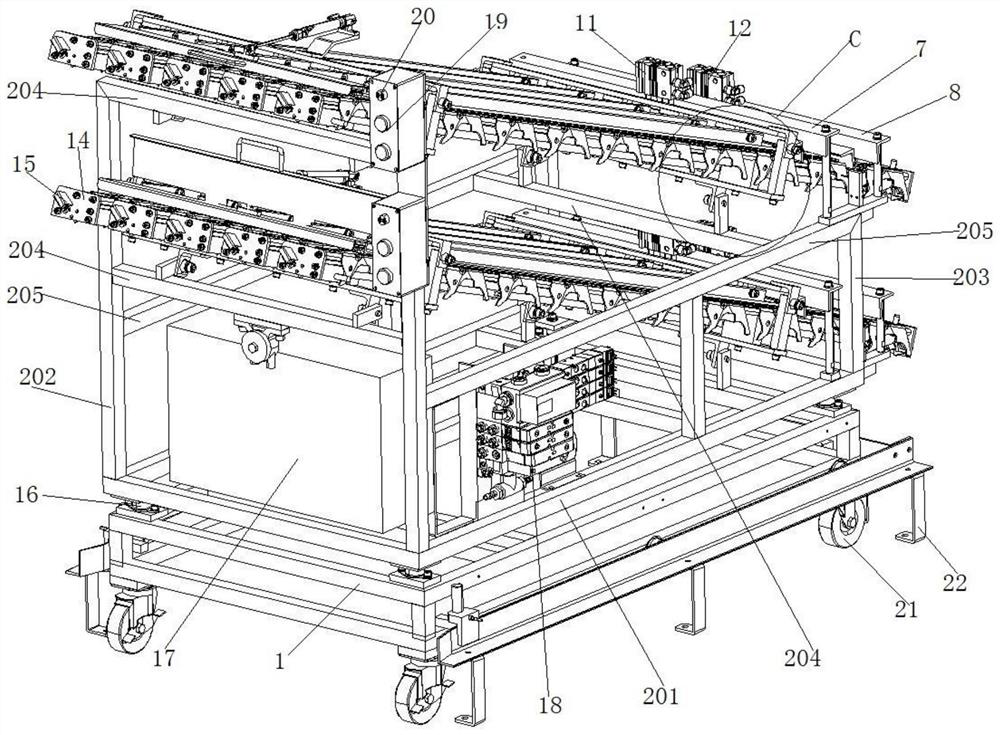

[0039] Such as Figure 1 ~ Figure 4 As shown, an automatic conveying material rack for small parts in an automobile welding line includes a bottom plate 1, a material bin bracket 2 is arranged above the bottom plate 1; a row of feeding components is arranged on the material bin bracket 2 with the least inclination , each of the feeding assemblies has at least one pair of sliding material guide rods 3 arranged in parallel, and the two ends of the sliding material guiding rods 3 are respectively provided with a material replenishment port and a material grabbing port; The first mounting frame 4 and the second mounting frame 5 are fixedly installed on the material bin bracket 2, the first mounting frame 4 is set close to the side of the material replenishment port, and the second mounting frame 5 is close to the One side of the material grabbing port is set; a pneumatic pull rod 401 is arranged above the first installation frame 4, and the end of the pneumatic pull rod 401 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com