Multichannel vacuum sublimation apparatus and using method thereof

A sublimation device and multi-channel technology, applied in sublimation, separation methods, chemical instruments and methods, etc., can solve the problems of low purification efficiency, complex structure, large amount of purified samples, etc., achieve convenient collection, avoid pollution, and improve purification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

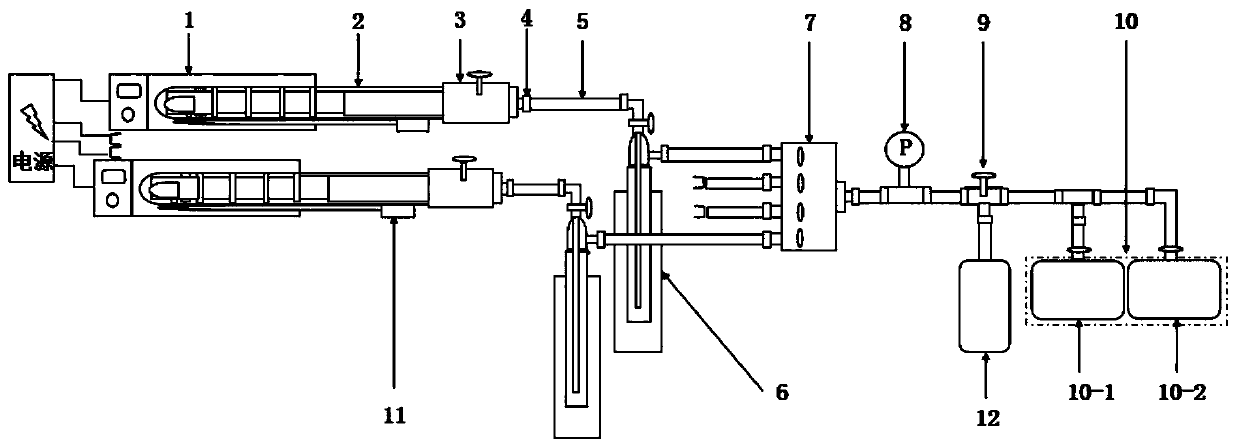

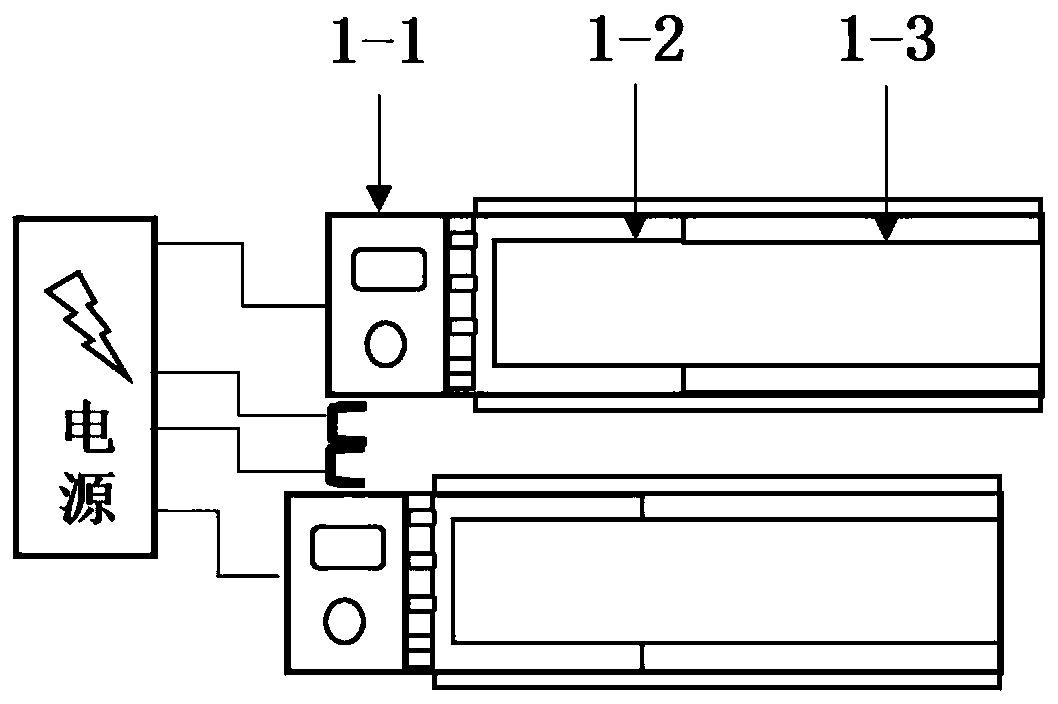

[0041] See figure 1 , is a schematic structural diagram of the deposition chamber of the multi-channel vacuum sublimation device provided in the embodiment of the present application when the deposition chamber is placed horizontally.

[0042] Specifically, the multi-channel vacuum sublimation device of the embodiment of the present application includes two deposition chambers 2 , two air extraction connection devices 3 and a multi-port normalization valve 7 , and one end of each air extraction connection device 3 is connected to the deposition chamber. port connection of body 2; where, as Figure 7 As shown, the multi-port normalizing valve 7 includes four pipelines 7-1, four on-off valves 7-2, a filter screen 7-3 and an adapter 7-4. After the four pipelines 7-1 are connected in parallel It is connected with the conversion joint 7-4, the four pipelines 7-1 are respectively connected in series with the four on-off valves 7-2, and the four pipelines 7-1 are connected in series...

Embodiment 2

[0066] In this example, the multi-channel vacuum sublimation device of Example 1 is used to test the multi-channel vacuum sublimation device based on the sublimation and purification effects of bibithiazole, bipyridine, and fluorenone compounds. The sample compounds involved are all poorly soluble, The thermal stability is good. Among them, the samples with serial numbers 1 to 3 in Table 1 are bidithiazole compounds, the sample with serial number 4 is a bipyridine compound, and samples 5 to 6 are fluorenone compounds. The specific experimental results are as follows 1 shown.

[0067] Due to the poor solubility of the above compounds, the crude products of the reactants were directly subjected to vacuum sublimation purification; after the first sublimation purification, the purity detection and yield calculation were not carried out, but the secondary sublimation purification was directly carried out, and the NMR or elemental analysis was detected. , the purity of the second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com