Nasal cavity cleaning actuator

A technology for actuators and nasal cavities, applied in inhalers, nebulizers for treatment, etc., can solve the problems of unsatisfactory spray effects, off-flying, fixed nozzle aperture, etc., and achieve soft atomization effects and fine spray particles. The effect of small diameter and increased comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

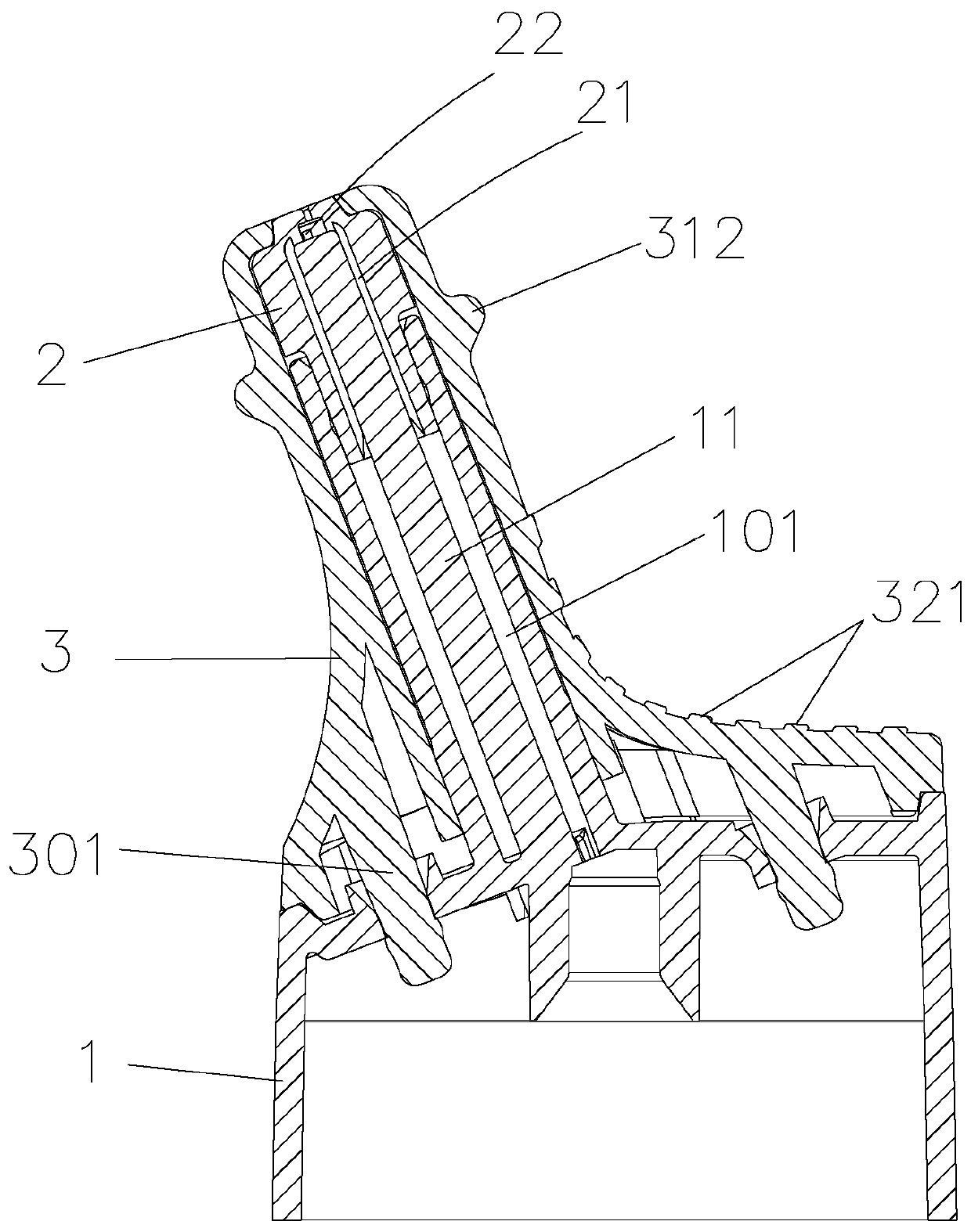

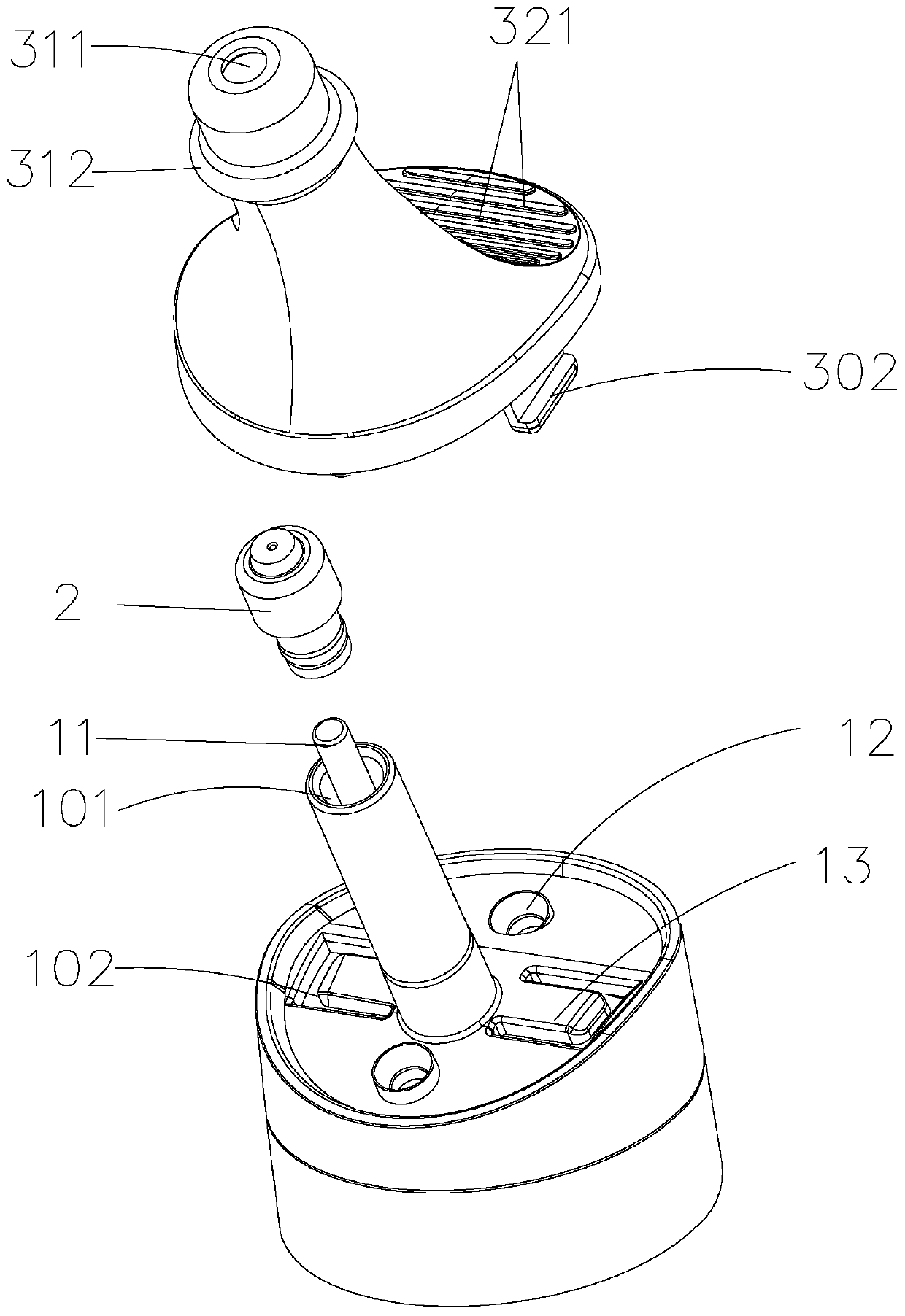

[0027] Such as Figure 1 to Figure 8 As shown, a nasal cleaning actuator includes a base 1 connected to the bottle, the top of the base 1 extends upwards to form a first liquid outlet channel 101 communicating with the inside of the bottle, the first outlet The end of the liquid channel 11 is connected with the atomizing nozzle 2, and the housing 1 is connected with the housing 3. The housing 3 includes a nozzle 31 for fixing the atomizing nozzle 2. The pressing part 32 that works together with the body 1, the center column 11 that can extend into the atomizing nozzle 2 is arranged on the seat body 1 and is located in the first liquid outlet channel 101, the inner wall of the atomizing nozzle 2 and the center column 11 is provided with a second liquid outlet channel 201 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com