Drive structure, main mechanical arm and auxiliary mechanical arm

A driving structure and manipulator technology, applied in the field of manipulators, can solve problems such as limited, unfavorable clamping workpiece adjustment and calibration, and the working arm cannot reach the installation position very accurately, so as to reduce the swing speed, facilitate adjustment and calibration, and adjust the accuracy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

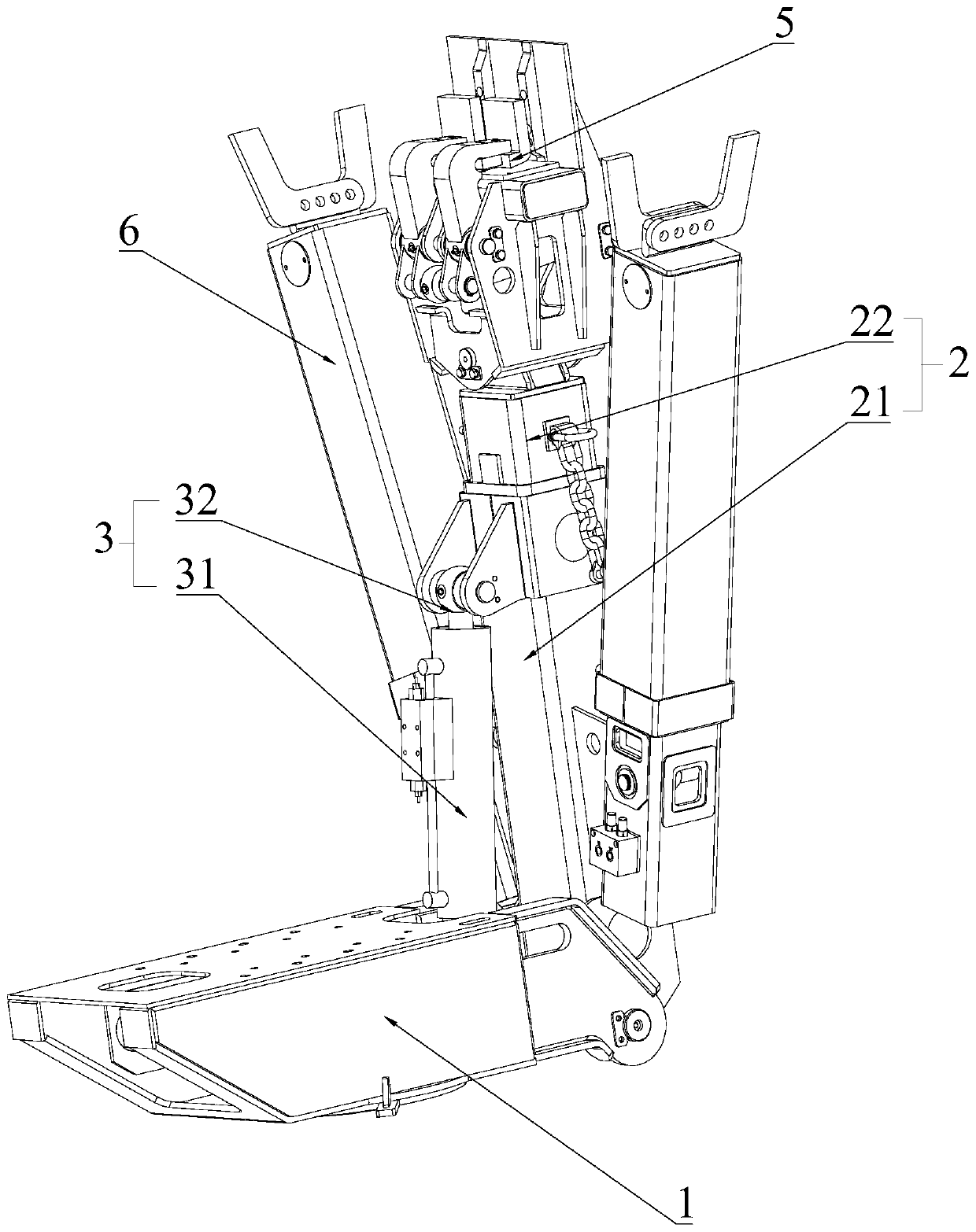

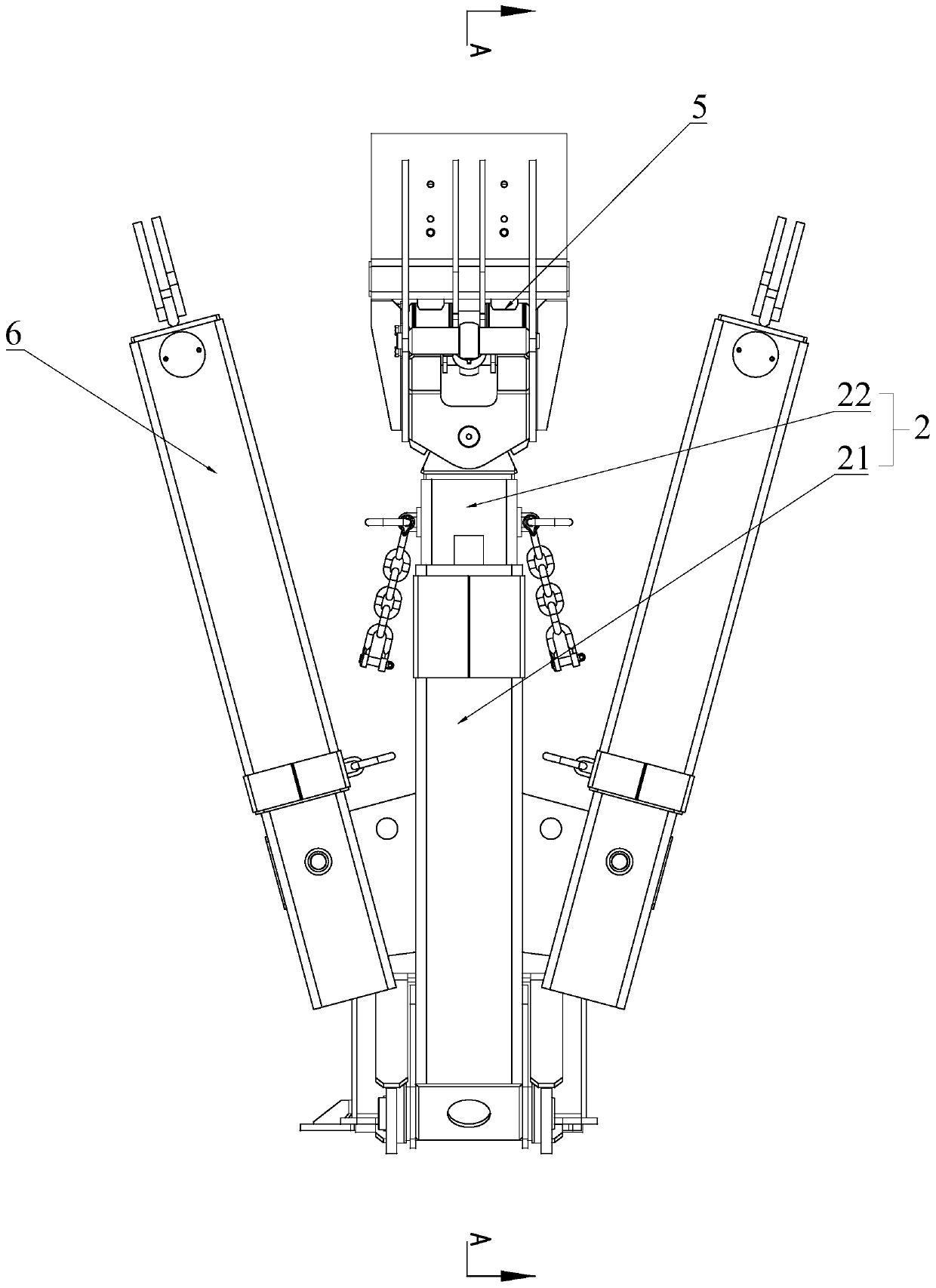

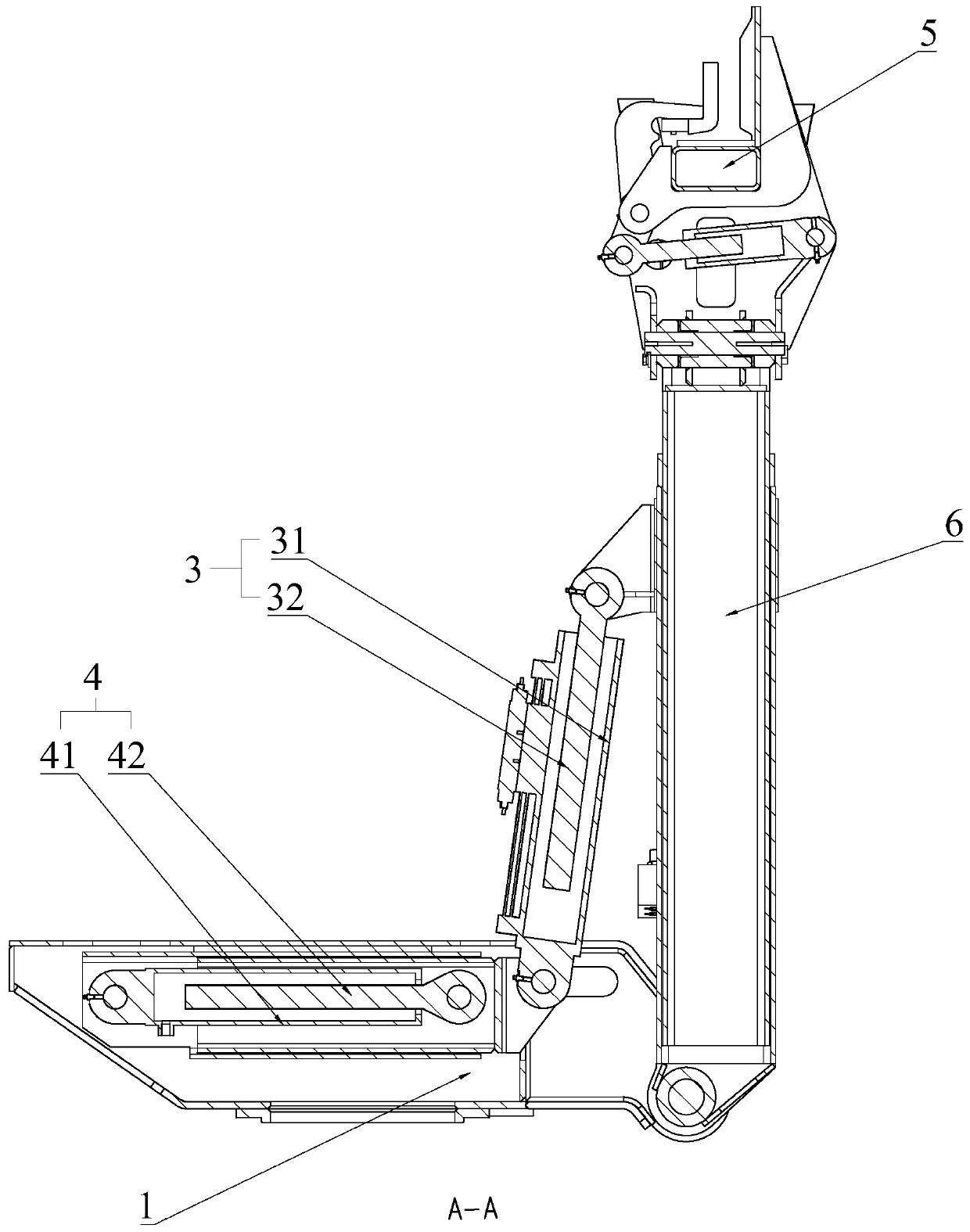

[0025] See figure 1 , figure 2 , image 3 As shown, the driving structure of the present invention includes a base 1 and a manipulator 2 hinged on the base 1. The manipulator 2 is hinged with a first driving member 3 that drives the manipulator 2 to rotate, and the first driving member 3 is connected with The second driving part 4 that changes the position of the first driving part 3 is arranged on the base 1. The position of the first driving member 3 is adjusted by the second driving member 4. When the manipulator 2 is rotated from the first position to the second position, the second driving member 4 of the front section adjusts the position of the first driving member 3 along the rotation direction of the manipulator 2, That is to say, the swing speed can be increased to achieve rapid swing. When the manipulator 2 quickly swings to the second position, the second drive member 4 adjusts the position of the first drive member 3, and the first drive member 3 does not operate t...

Embodiment 2

[0029] See figure 1 , figure 2 , image 3 As shown, the driving structure of the present invention includes a base 1 and a manipulator 2 hinged on the base 1. The manipulator 2 is hinged with a first driving member 3 that drives the manipulator 2 to rotate, and the first driving member 3 is connected with The second driving member 4 that changes the position of the first driving member 3.

[0030] The first driving member 3 includes a first cylinder 31 and a first telescopic rod 32 slidably connected in the first cylinder 31, and the first telescopic rod 32 is hinged to the manipulator 2. It can be adjusted effectively with the manipulator 2. The second driving member 4 is arranged on the base 1, and the second driving member 4 includes a second cylinder 41 and a second telescopic rod slidably connected in the second cylinder 41 42. The second cylinder 41 is fixedly connected to the base 1, and the end of the second telescopic rod 42 is connected to the first driving member 3. ...

Embodiment 3

[0033] The basic structure is the same as the second embodiment of the working arm structure, except that the second telescopic rod 42 is fixedly connected to the first cylinder 31. The fixed connection refers to the structure that can connect the second telescopic rod 42 and the first cylinder 31 fixedly, that is, the fixed connection is realized when the first driving member 3 and the second driving member 4 are running for some time, that is, the first driving The angle between the part 3 and the second driving part 4 is constant. When the manipulator is adjusted to operate, the first driving part 3 and the second driving part 4 will inevitably run at the same time. The first driving part is adjusted along the rotation direction of the manipulator 2 through the second driving part 4 The position of the part 3 can speed up the swing speed and achieve rapid swing, or adjust the position of the first driving part 3 in the opposite direction of the rotation of the manipulator 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com