A method to prevent the roof from being pressed when the working face and the withdrawal channel are connected

A technology of retraction channel and working face, which is applied in the field of preventing the top plate from pressing when the working face and the retraction channel are connected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

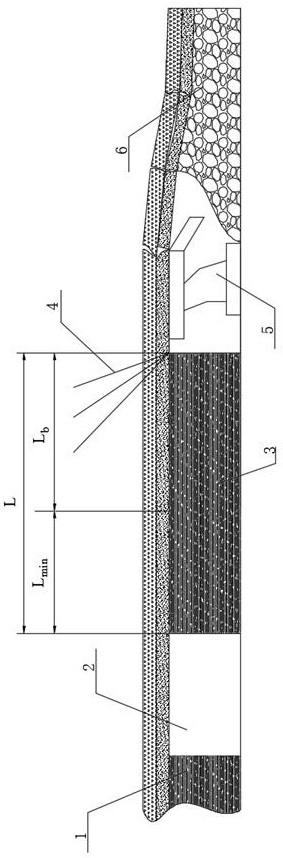

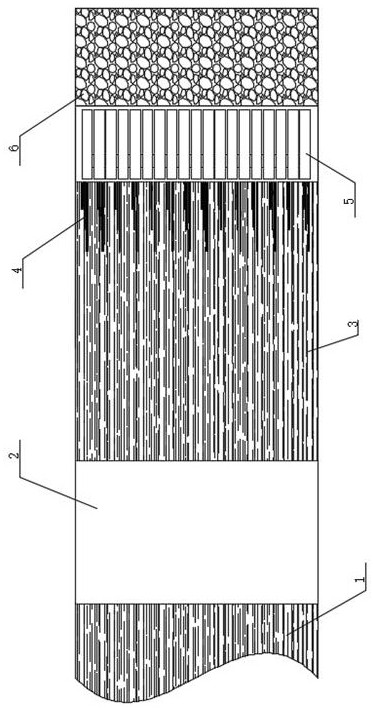

[0028] In order to explain the technical objectives, features and effects of the present invention more clearly, the present invention will be further described in conjunction with the accompanying drawings.

[0029] The 310011 mining face of a certain mine is currently mainly mining No. 2 and No. 3 coal seams. The thickness of the coal seam is 2.8m-4.5m, the average thickness is 3.8m, and the inclination angle of the coal seam is 1°-3°. Full-height fully mechanized top coal caving mining method. The top directly above the coal seam is medium-fine-grained sandstone with a thickness of about 6.4m; further up is gray medium-fine-grained sandstone with a thickness of 8.3m, and the rock is relatively hard. The specific implementation steps are as follows:

[0030] (1) Determine the lithology of the upper old top of the coal seam as fine sandstone with a thickness of 8.3m and a distance of 6.4m between the two layers through the histogram of the mine drilling, which is used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com