Device for taking parts through corrugated pipe of automobile shock absorber dust cover

A bellows and shock absorber technology, applied in the field of automobile manufacturing equipment, can solve the problems of easy breakage and low efficiency of shock absorber dust cover, so as to avoid danger, reduce labor costs and production risks, and improve the level of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

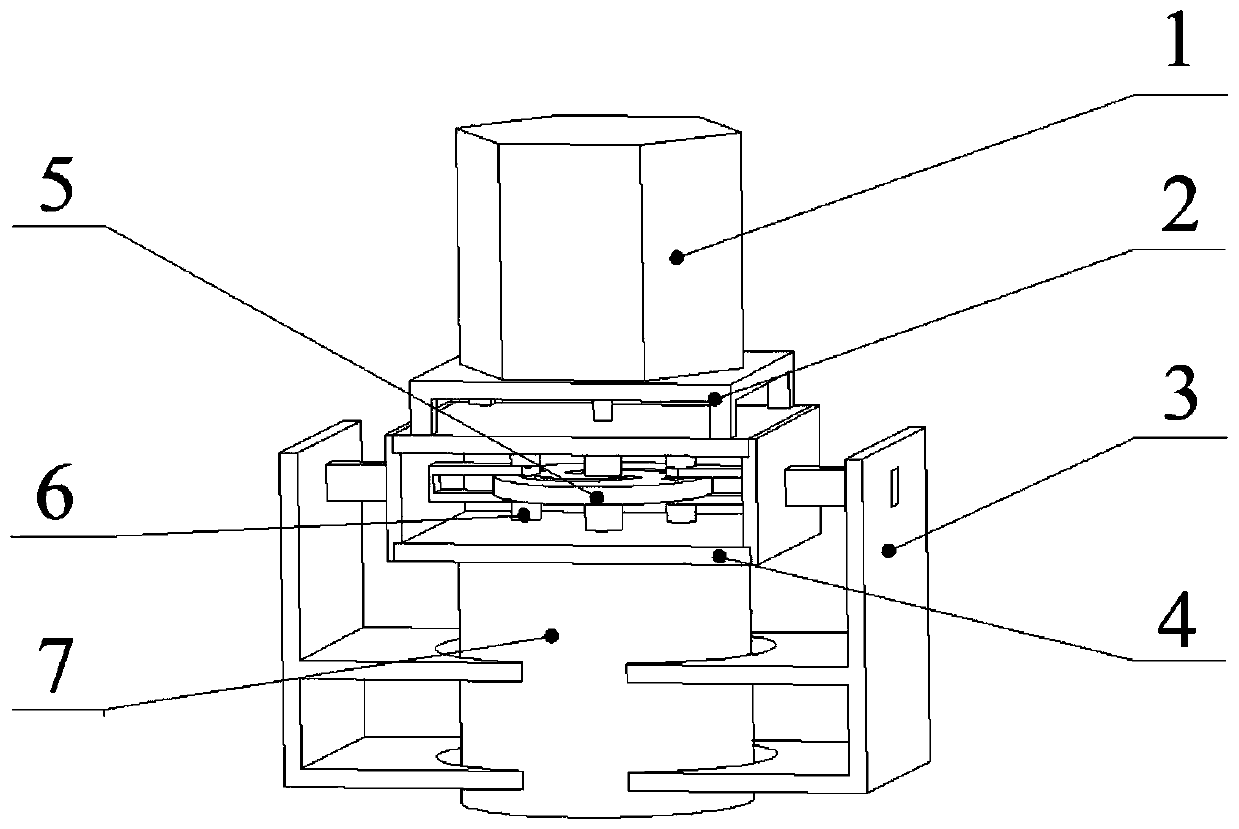

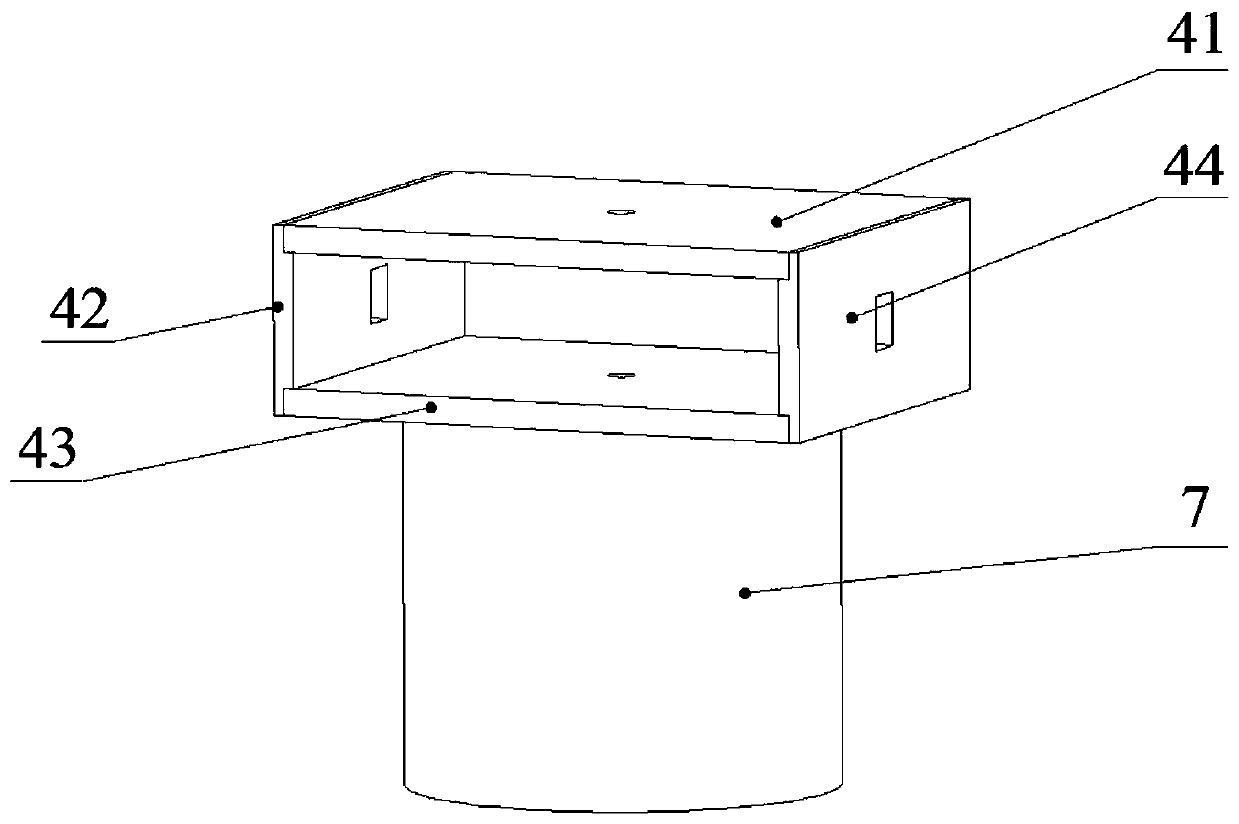

[0032] Such as figure 1 and figure 2 As shown, a device for taking parts through the bellows of the automobile shock absorber dust cover includes a frame, a driving device and a gripping arm assembly 3, the frame includes a drive box 4 and a motor support 2, and the drive box 4 includes The box body of square frame shape is spliced by top board 41 , bottom board 43 , left side board 42 and right side board 44 , and motor support 2 is fixedly installed above top board 41 .

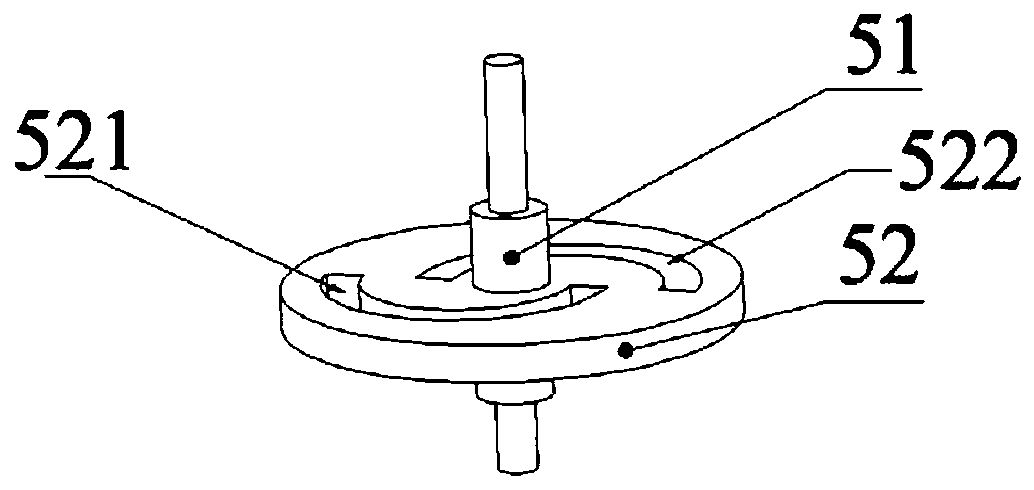

[0033] Such as Figure 3 to Figure 7 As shown, the drive device includes a drive motor 1 and a drive mechanism 5, the drive motor 1 is fixedly mounted on the motor support 2, the drive mechanism 5 includes a drive shaft 51 and a drive disc 52, and the drive shaft 51 is connected to the output shaft of the drive motor 1 , the drive shaft 51 stretches into the inside of the drive box 4 and is fixedly equipped with a drive disc 52, the drive disc 52 is disc-shaped, the drive shaft 51 and the drive disc 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com