Robot clamping tool

A technology for clamping tooling and robots, which is applied in the field of robots, can solve problems such as inability to effectively adapt to workpieces with different diameters, unstable clamping, and damage to workpieces, so as to achieve uniform force, improve stress concentration, and protect workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

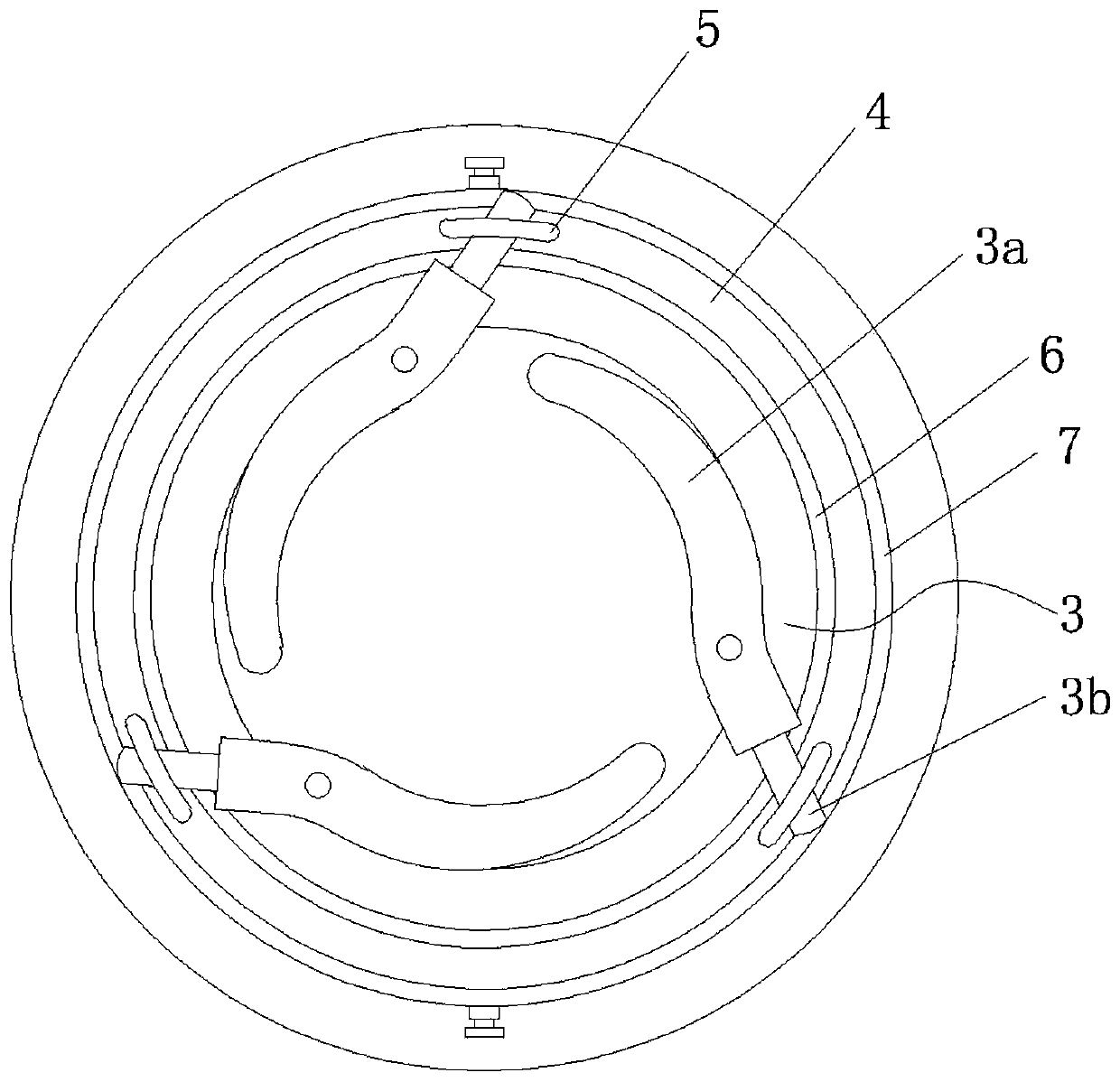

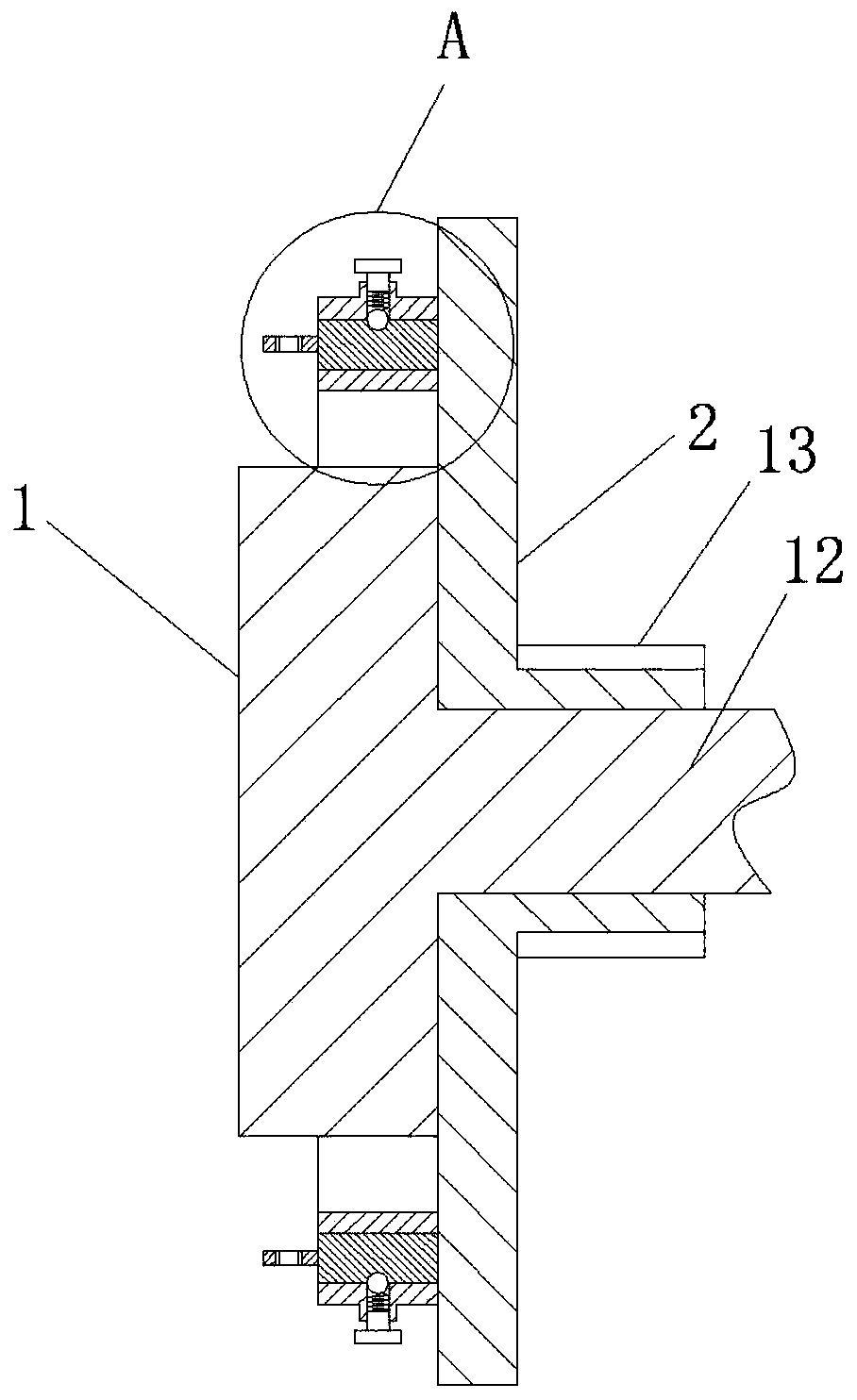

[0022] figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 It is a schematic diagram of the cooperation structure of the drive disk and the base disk of the present invention; image 3 for figure 2 The radial cross-sectional structural schematic diagram of ; Figure 4 for image 3 Schematic diagram of the enlarged structure at point A;

[0023] As shown in the figure: the clamping tooling of the robot in this embodiment includes a base plate 1, a drive plate 2 that rotates with the base plate, and several clamping arms arranged on the base plate symmetrically with the center axis of the base plate as the central axis. 3 and the unloading ring 4 arranged on the driving disk, the unloading ring and the driving disk are arranged coaxially, the clamping arm driver 5 corresponding to each clamping arm is connected on the described unloading ring 4, and the clamping arm There is a driving hole 5a on the driving part 5, the middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com