Preparation method of plant-based concentrated broth

A plant-based and broth technology, which is applied in the field of plant-based concentrated broth preparation, can solve problems such as insufficient mellowness and taste of broth, and achieve the effects of delicious and mellow taste, satisfying dietary needs, and rich and harmonious meat aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing plant-based concentrated broth, characterized in that it comprises the following steps:

[0039] (1) mixing vegetable protein with water to obtain a mixture;

[0040] The content difference of at least 4 kinds of amino acids in the vegetable protein and the animal protein is within 10%;

[0041] (2) Adding protease to the mixture obtained in step (1), at a temperature of 50-60°C, under natural pH conditions (pH=5-7), after three enzymolysis, the temperature was raised to 85°C to inactivate the enzyme for 10 minutes to obtain Plant protein enzymatic hydrolyzate;

[0042] (3) Add auxiliary materials to the enzymatic hydrolyzate of plant protein obtained in step (2) and mix, heat and react at a temperature of 80-150° C. for 0.5-4 hours to obtain concentrated plant-based broth.

[0043] The vegetable protein in step (1) is not particularly limited, and the vegetable protein is preferably at least one of soybean protein, peanut protein, sunflower pro...

Embodiment 1

[0053] Basic Example 1 A kind of preparation method of chicken-flavored plant-based concentrated broth

[0054] (1) mixing soybean protein, corn protein and peanut protein in a mass ratio of 2:4:4 to obtain vegetable protein;

[0055] (2) Mix the vegetable protein prepared in step (1) with water according to the ratio of solid to liquid at 1:10 to obtain a mixture;

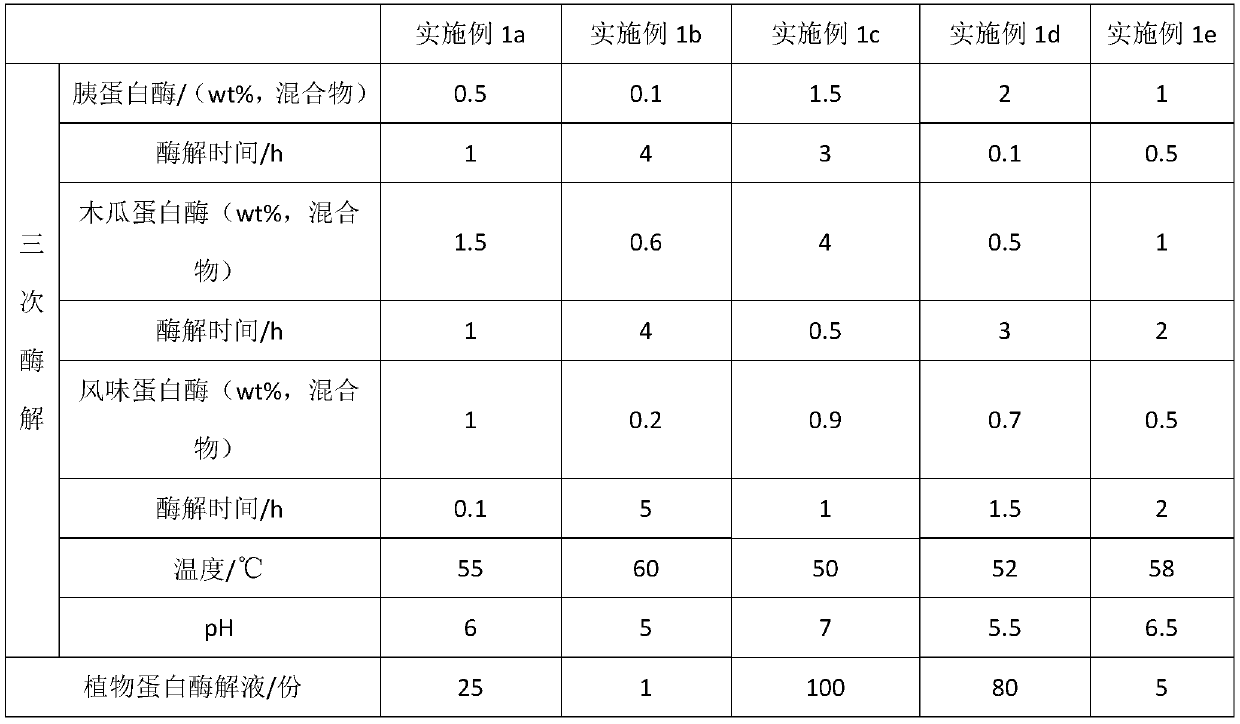

[0056] (3) At a temperature of 50-60°C and a natural pH (5-7), add 0.1-2% trypsin (wt%, mixture) to the mixture prepared in step (2) to enzymatically hydrolyze 0.1- 4h, 0.1-4% papain (wt%, mixture) enzymolysis for 0.5-4h, 0.2-1% flavor protease (wt%, mixture) enzymolysis for 0.1-5h, heat up to 85°C to inactivate the enzyme for 10min, to obtain plant protein enzymatic hydrolyzate ;

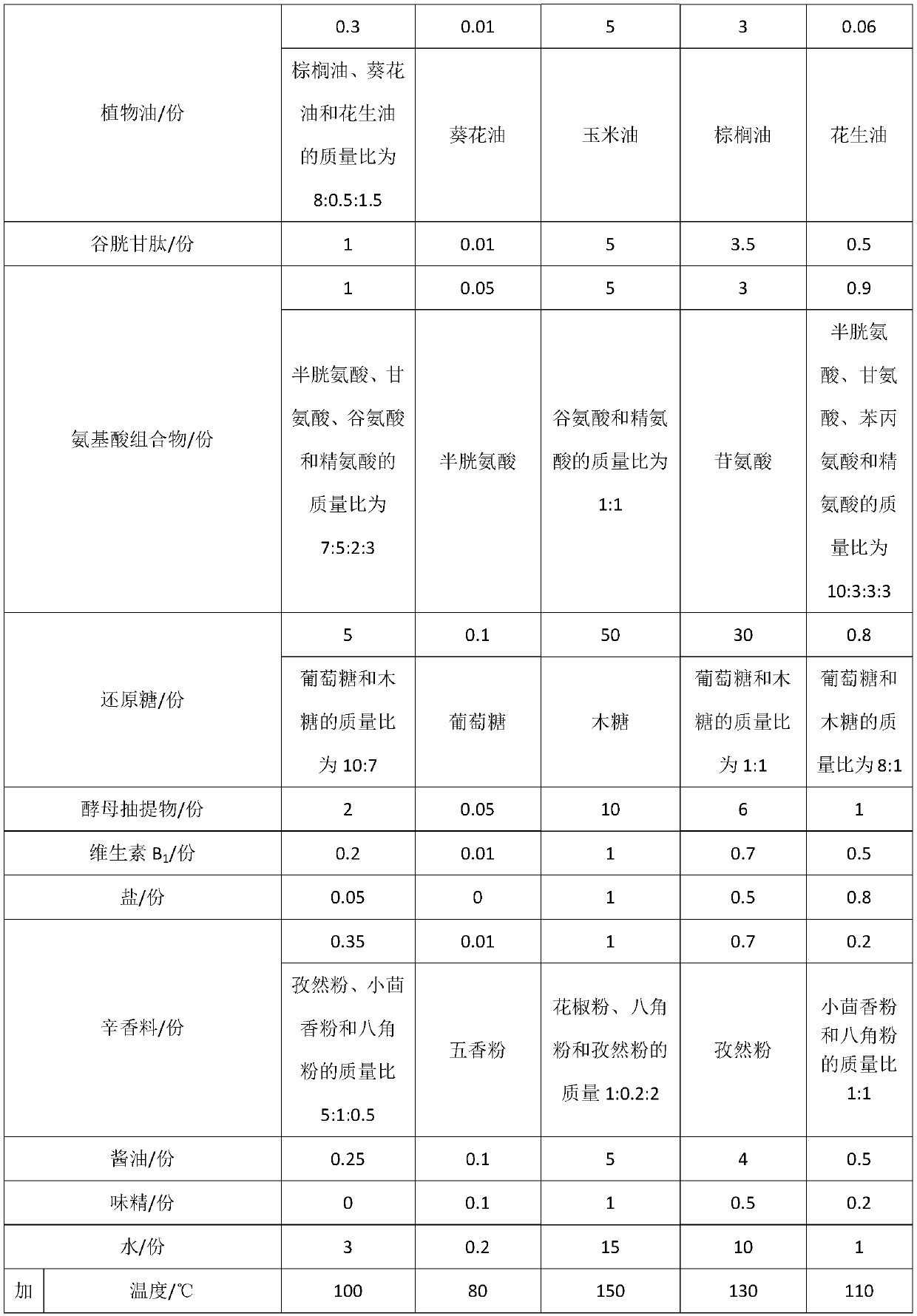

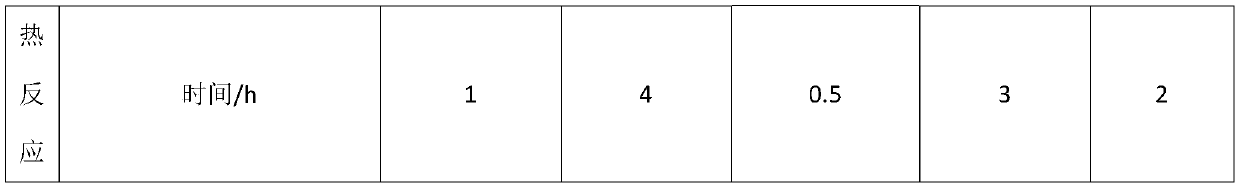

[0057] (4) Add auxiliary materials to the enzymatic hydrolyzate of plant protein obtained in step (3) and mix evenly, adjust the pH to 7.5, and react at 80-150°C for 0.5-4h to obtain concentrated plant-based broth, specifically, the ...

Embodiment 2

[0073] Basic Example 2 A method for preparing pork-flavored plant-based concentrated broth

[0074] (1) mixing soybean protein, wheat protein and peanut protein in a mass ratio of 2.5:2.5:5 to obtain vegetable protein;

[0075] (2) Mix the vegetable protein prepared in step (1) with water according to the ratio of solid to liquid at 1:5 to obtain a mixture;

[0076] (3) At a temperature of 50-60°C and a natural pH (5-7), add 0.1-2% trypsin (wt%, mixture) to the mixture prepared in step (2) to enzymatically hydrolyze 0.1- 4h, 0.1-4% papain (wt%, mixture) enzymolysis for 0.5-4h, 0.2-1% flavor protease (wt%, mixture) enzymolysis for 0.1-5h, heat up to 85°C to inactivate the enzyme for 10min, to obtain plant protein enzymatic hydrolyzate ;

[0077] (4) Add auxiliary materials to the enzymatic hydrolyzate of plant protein prepared in step (3), mix well, adjust the pH to 7.5, and react at 80-150°C for 0.5-4h to obtain concentrated plant-based broth, specifically, the plant The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com