A bottle cap positioning device for laser marking of bottle caps

A positioning device and bottle cap technology, which is used in laser welding equipment, typewriters, transportation and packaging, etc., can solve the problems of poor coding quality, affecting processing efficiency, and no bottle cap positioning, and achieve automatic unloading work, The effect of low production cost and convenient coding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

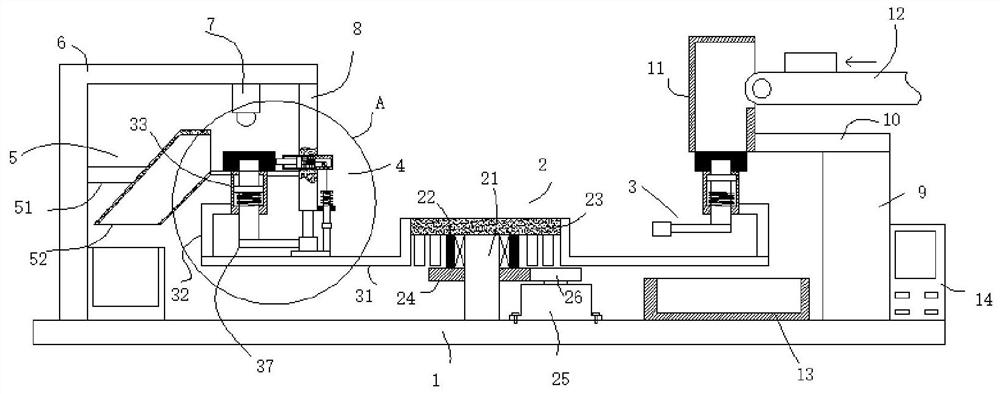

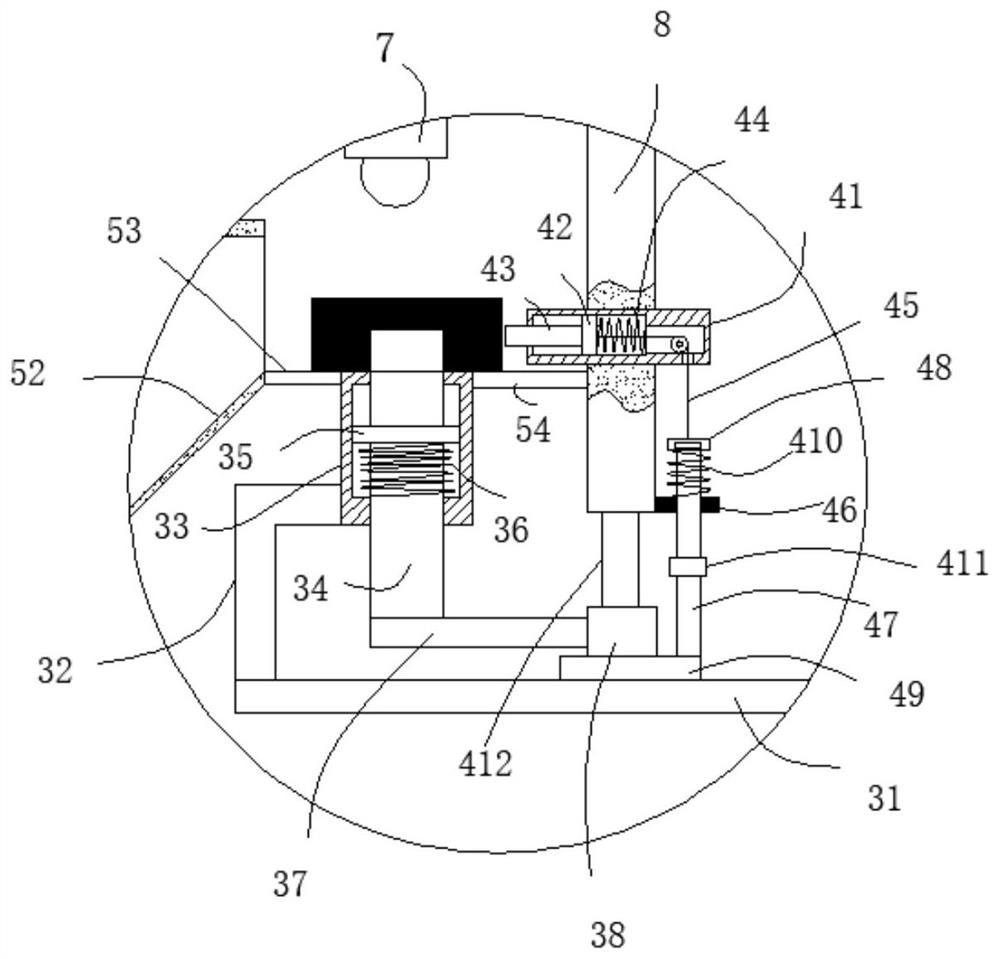

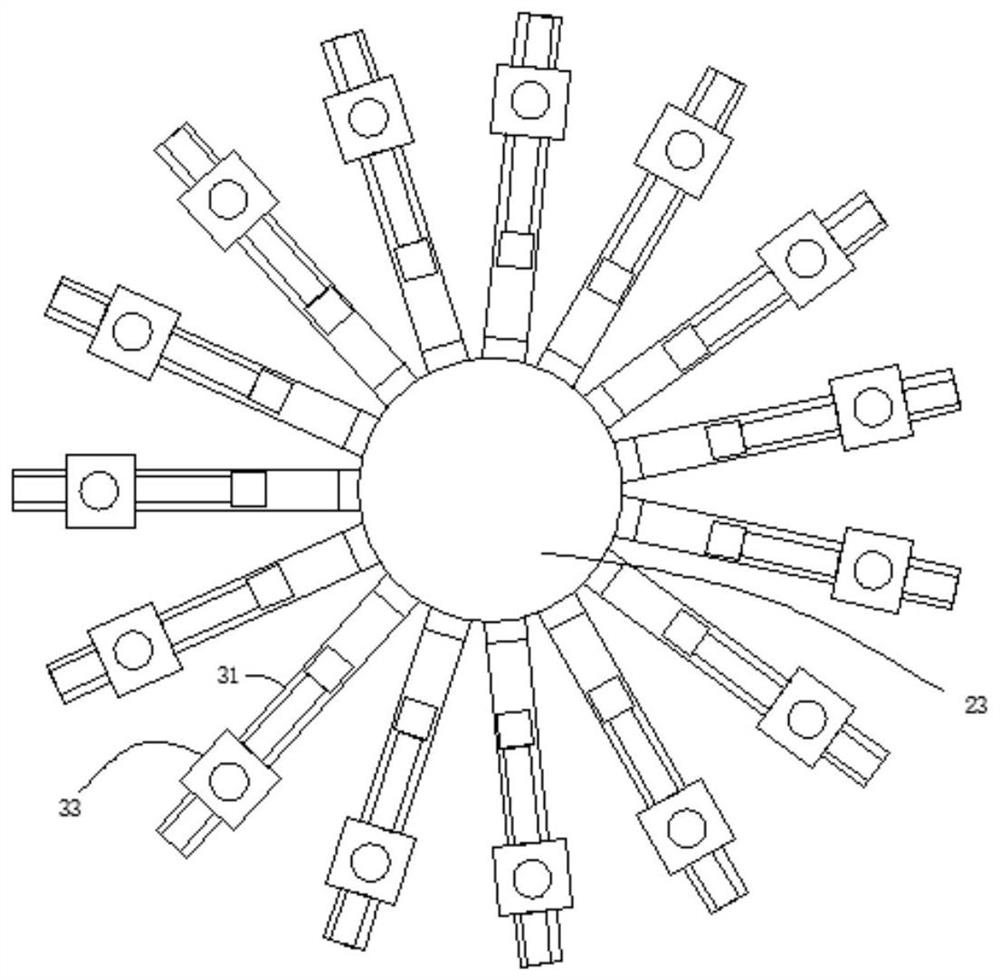

[0027] refer to Figure 1-6 , a bottle cap positioning device for laser marking, comprising a base 1 and a controller 14 fixed on the base 1, an L-shaped fixing plate 6 is fixed on the base 1, and a vertical The laser marking terminal 7 and the mounting plate 8 are equipped with a stripping assembly 4 on the mounting plate 8, a receiving assembly 5 matching the stripping assembly 4 is installed on the L-shaped fixed plate 6, and a driving assembly 2 is installed on the base 1. The driving assembly 2 is fixed with feeding assemblies 3 arranged in a circular array, the leftmost feeding assembly 3 is located below the laser marking dock 7, the base 1 is fixed with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com