Building hose leather sheath assembling machine

A technology for assembling machines and holsters, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency and high labor intensity of manual suits, and achieve the effect of reducing labor intensity and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

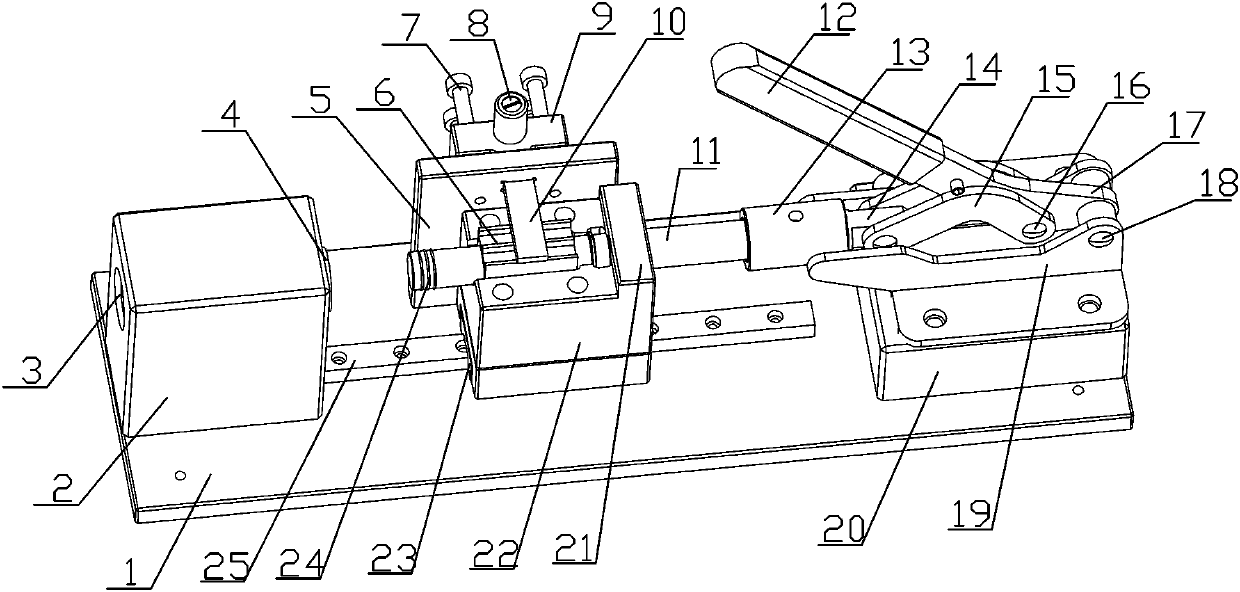

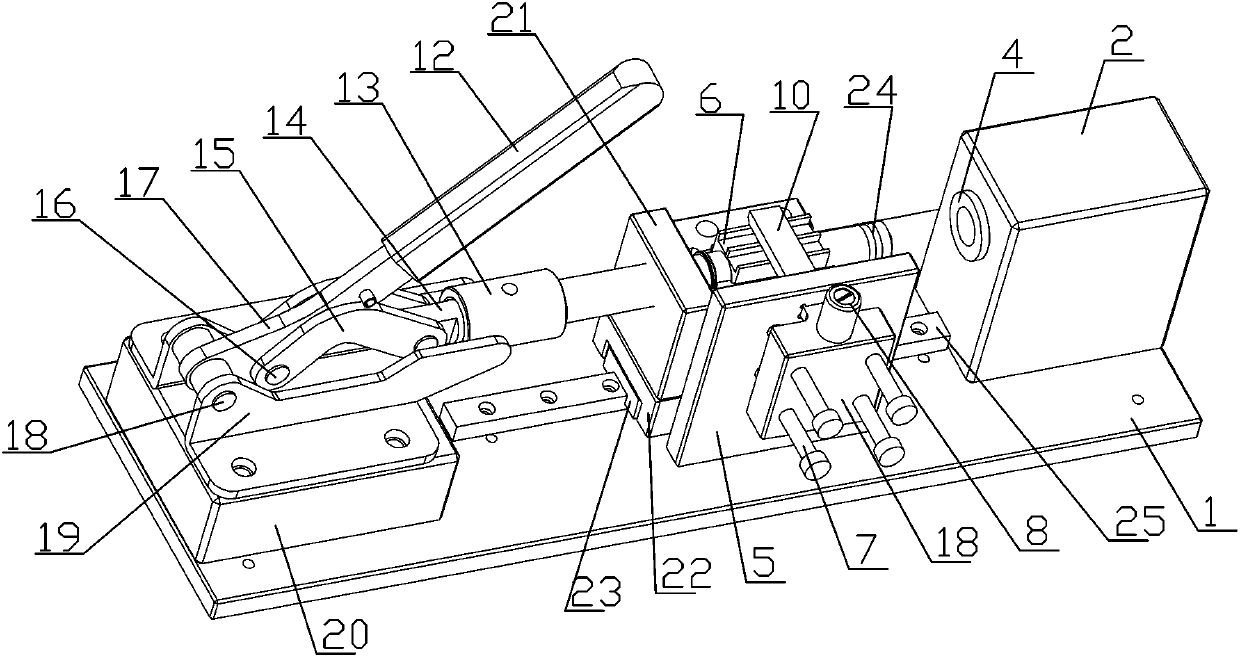

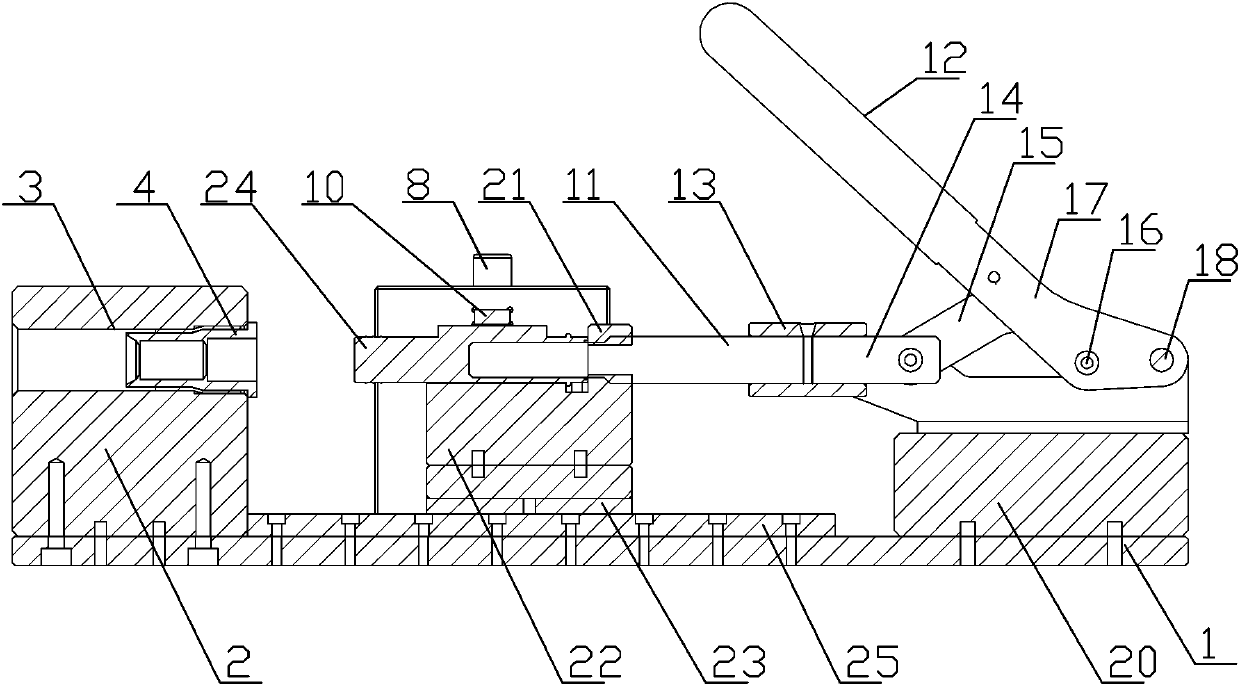

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see Figure 1-3 , a holster assembly machine for construction hoses, which includes a base plate 1, a slide rail 25 is installed at the middle part of the base plate 1, and a sliding sleeve 23 is installed on the slide rail 25 through sliding fit, and the sliding A slide block 22 is fixed on the top of the cover 23, and a pipe clamping mechanism for clamping the pipeline 24 to be assembled is installed on the side wall of the slide block 22; The side is provided with a holster positioning seat 2, and a holster positioning hole 3 is processed on the holster locating seat 2, and a connecting rod propulsion mechanism is installed at the other end of the slide rail 25, and the connecting rod propulsion mechanism and the slider 22 Match and promote it to slide along the slide rail 25. Through the hose holster assembly machine described above, the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com