Sewage and sludge treatment device with reciprocating scraping plate mechanism

A sludge treatment and scraper technology, which is applied to the feeding/discharging device of the settling tank, settling tank, filtration circuit, etc., can solve the problems of corrosion of the box, easy blockage of the sewage outlet, and deposition of sludge, etc., and achieve improvement Working environment, guarantee of sewage discharge function, effect of stable sewage discharge function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

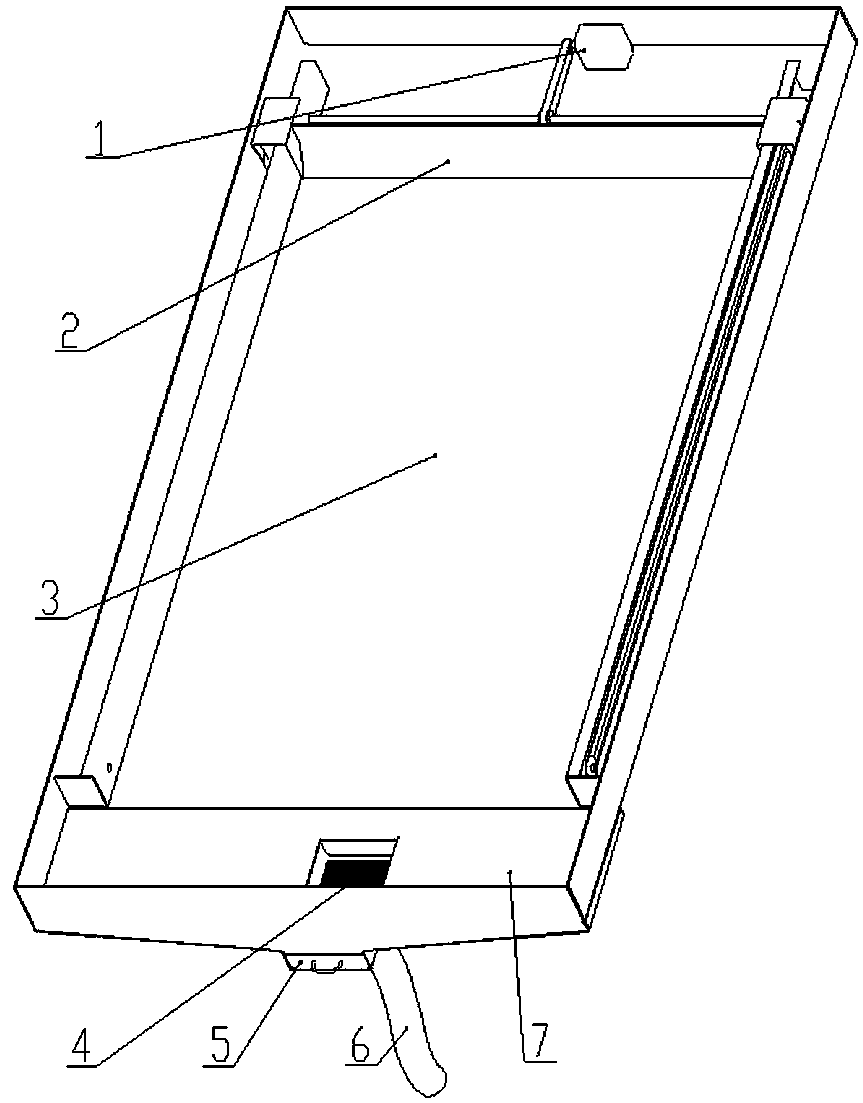

[0022] Such as figure 1 A sewage and sludge treatment device with a reciprocating scraper mechanism is shown, which is characterized in that it includes a sewage collection tank 3, a diversion chute 7, a filter pool 4, a filter screen 5, and is used to scrape the sewage collection tank 3 The scraper assembly 2 that deposits the sludge and the drive assembly 1 that drives the movement of the scraper assembly 2; the sewage collection tank 3 is installed at the bottom of the garbage compression tank, and the garbage compression tank corresponds to the diversion area of the sewage collection tank 3 Sewage holes are provided in the area of the bottom plate of the box body, and the diversion chute 7 is arranged in the sewage collection tank 3. The bottom of the diversion chute 7 is connected to the filter pool 4, and the middle of the filter pool 4 is connected to the filter screen 5. The drive assembly 1 is symmetrically arranged on the On both sides of the sewage collection ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com