Amorphous alloy golf club head and manufacturing method thereof

A golf club head, amorphous alloy technology, applied in golf balls, golf clubs, sports accessories, etc., can solve the problems of amorphous and crystalline mixtures, etc., to improve the ability to form amorphous, ensure quality, and good energy transfer performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

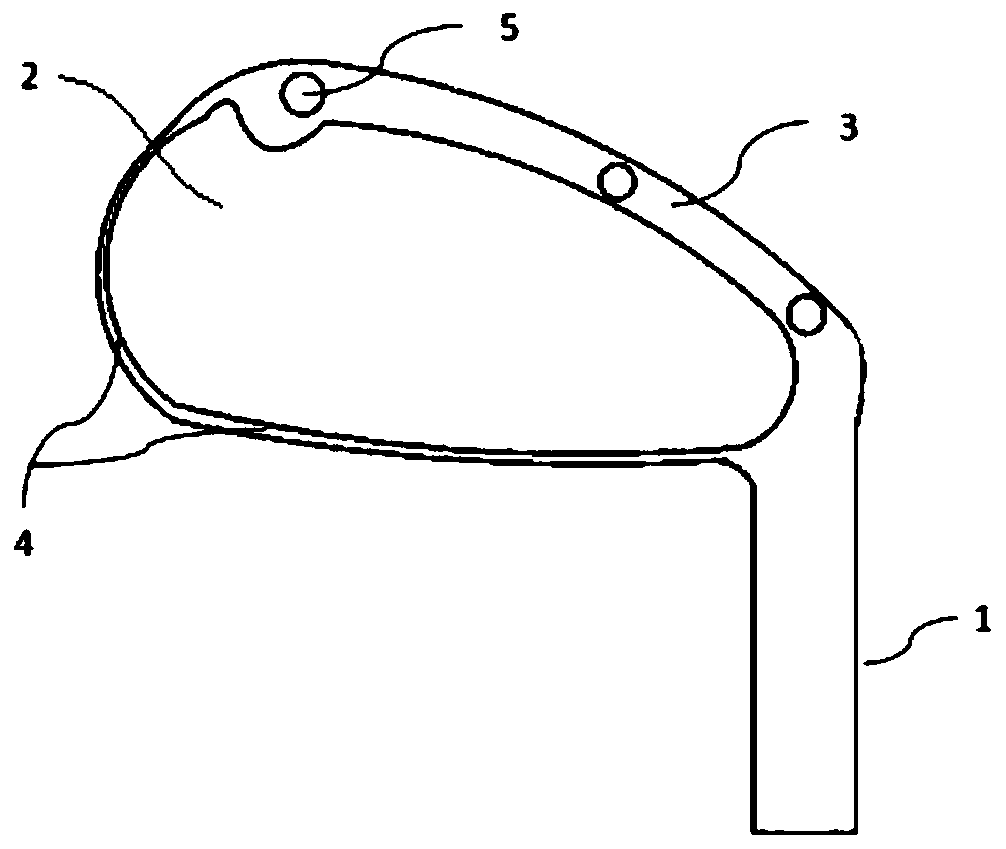

[0067] like Figure 4 As shown, an amorphous alloy golf club head of the present invention is integrally cast from an amorphous metal material, including:

[0068] a neck for coupling with the club;

[0069] a batting panel attached to the bottom of said neck;

[0070] a peripheral wall positioned behind the ball striking panel, the ball striking panel and peripheral wall forming a rear concave cavity;

[0071] The peripheral wall body includes a thin-walled portion enclosing the upper edge and the rear side edge of the ball striking panel, and a section of thick-walled portion enclosing the bottom of the ball striking panel rear;

[0072] A pad, embedded in the thick-walled part, is used to reduce the casting thickness of the thick-walled part; the embedded pad is provided with 3 pillars,

[0073] One end of each pillar is fixedly connected to the block body, and the other end of the pillar has an exposed surface that is not covered by the above-mentioned peripheral wall; ...

Embodiment 2

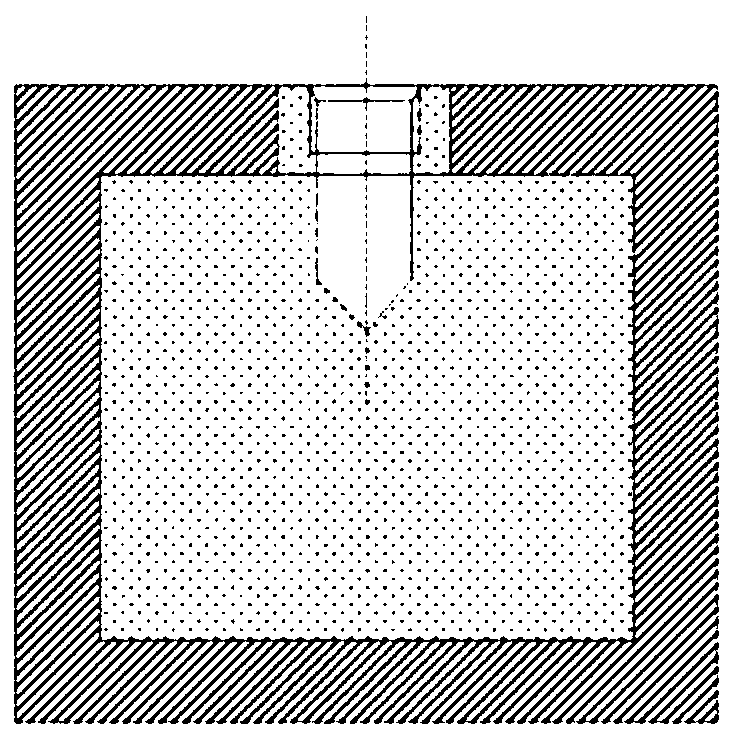

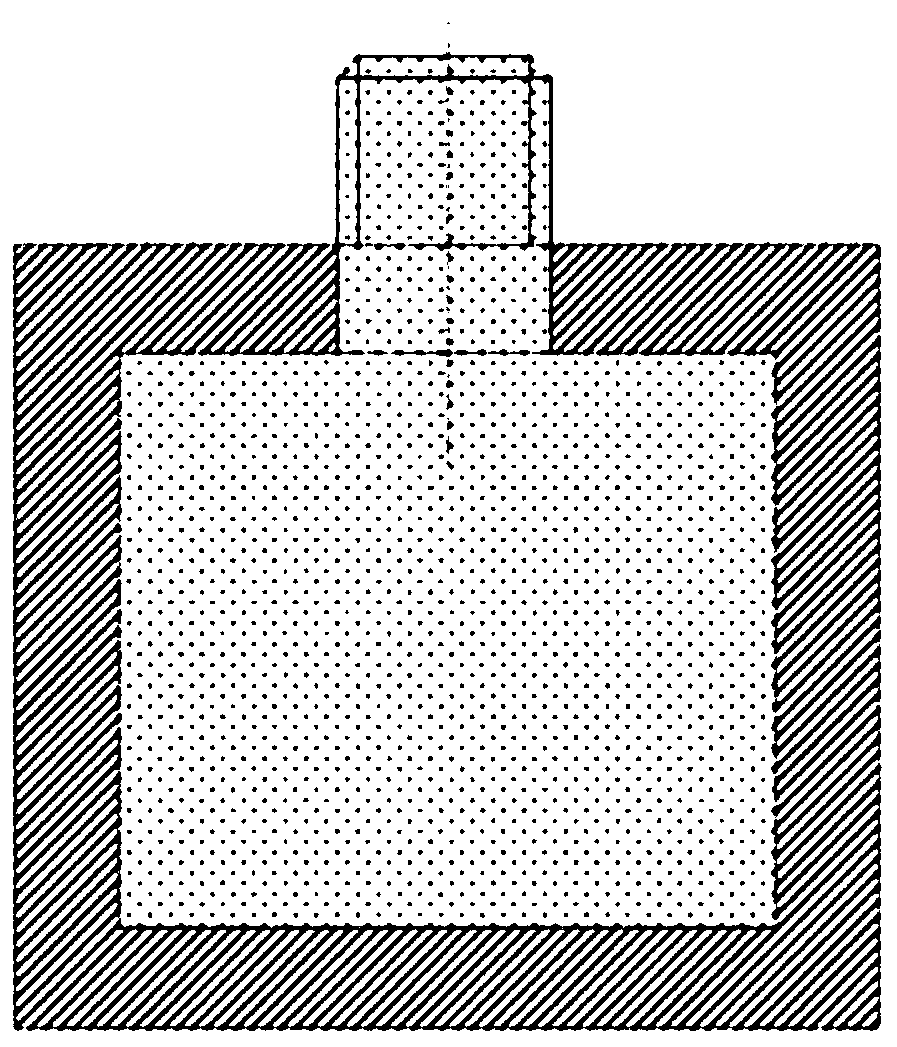

[0075] like image 3 As shown, an amorphous alloy golf club head of the present invention is integrally cast from an amorphous metal material, including:

[0076] a neck for coupling with the club;

[0077] a batting panel attached to the bottom of said neck;

[0078] a peripheral wall positioned behind the ball striking panel, the ball striking panel and peripheral wall forming a rear concave cavity;

[0079] The peripheral wall body includes a thin-walled portion enclosing the upper edge and the rear side edge of the ball striking panel, and a section of thick-walled portion enclosing the bottom of the ball striking panel rear;

[0080] A spacer, embedded in the thick-walled part, is used to reduce the casting thickness of the thick-walled part; the embedded spacer is provided with 3 metal pillars,

[0081] One end of the metal prop is fixedly connected to the spacer body, the other end of the metal prop has a bare section, the outer wall of the bare section is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com