Automatic vegetable vending machine with automatic bagging function

An automatic, vegetable machine technology, applied in coinless or similar appliances, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve vegetable damage, inconvenient and humane problems, such as avoiding waste, avoiding maintenance troubles, and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

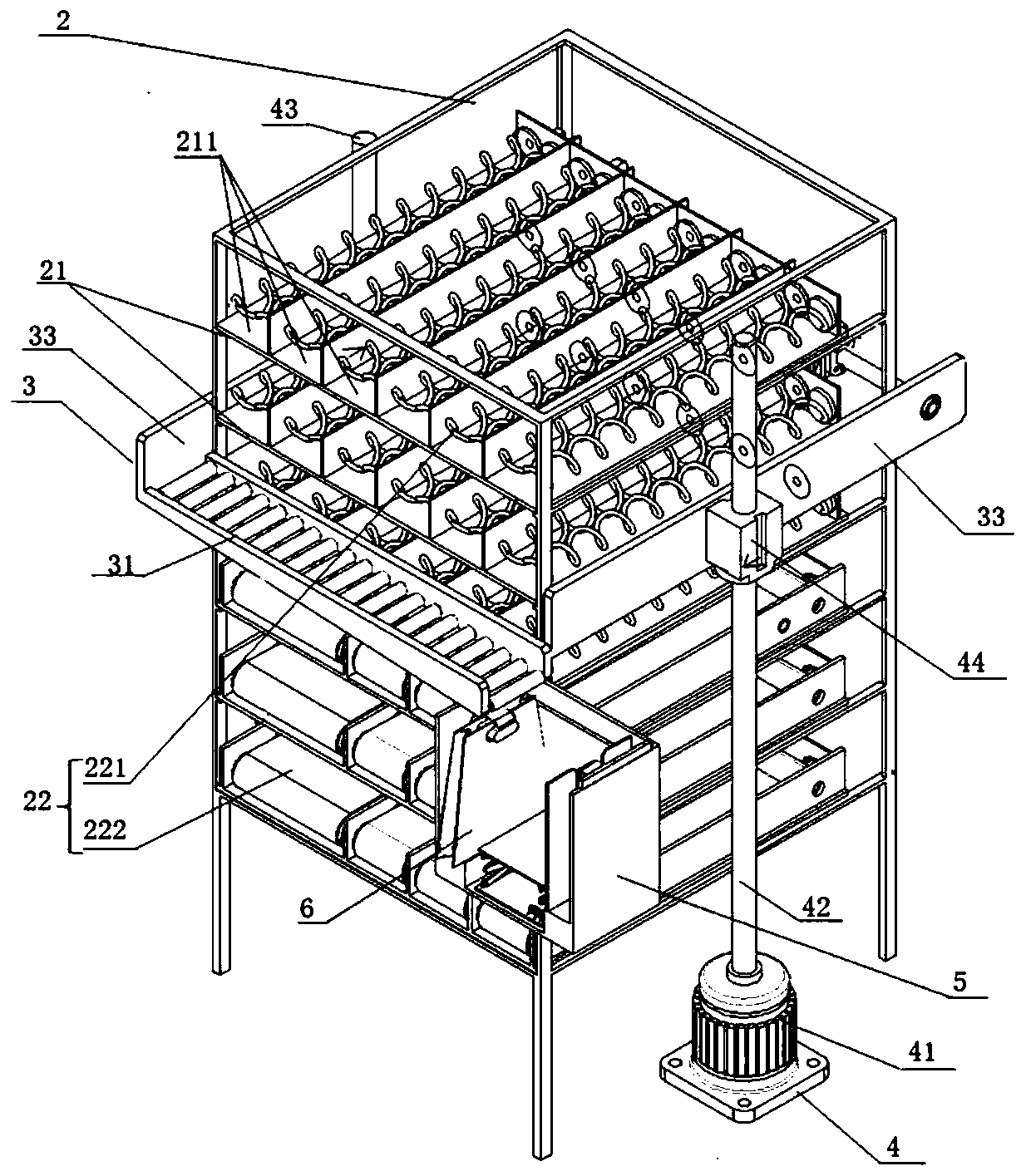

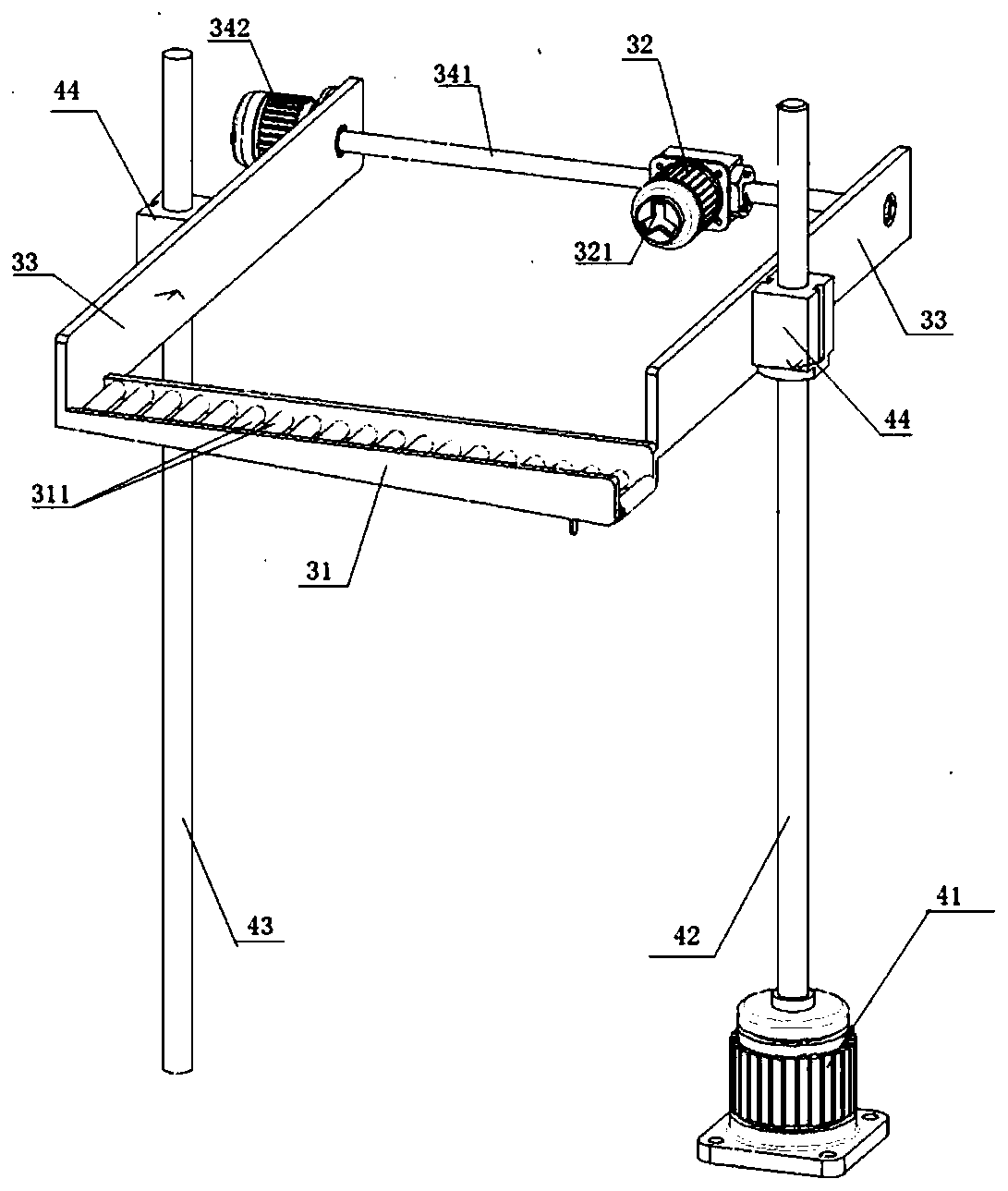

[0045] An automatic bagging vending machine, such as Figure 1~5 As shown, the box shell 1 and the shelf 2 arranged in the box shell 1 are included. The shelf 2 has a plurality of shelf layers 21, and each shelf layer 21 has a plurality of parallel cargo slots 211, and each cargo slot 211 is A delivery mechanism 22 is provided, and the automatic vegetable vending machine also includes a pallet unit 3, a pallet lifting unit 4 and an automatic bagging unit 5, wherein: the pallet unit 3 is surrounded by the shelf 2 and has a The delivery pallet 31 and the delivery motor 32 located at the rear side of the shelf 2, the delivery motor 32 can move along the direction in which the cargo slots 211 are arranged, and can be connected to the delivery mechanism 22 of each cargo slot 211 through a clutch mechanism; The pallet lifting unit 4 is used to drive the pallet unit 3 to lift, so that the pallet unit 3 moves to the position corresponding to each shelf layer 21; 3 lifting.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com