Modular robot self-repair simulation system and method

A simulation system, robot technology, applied in the field of robots, to meet the needs of use, good self-repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

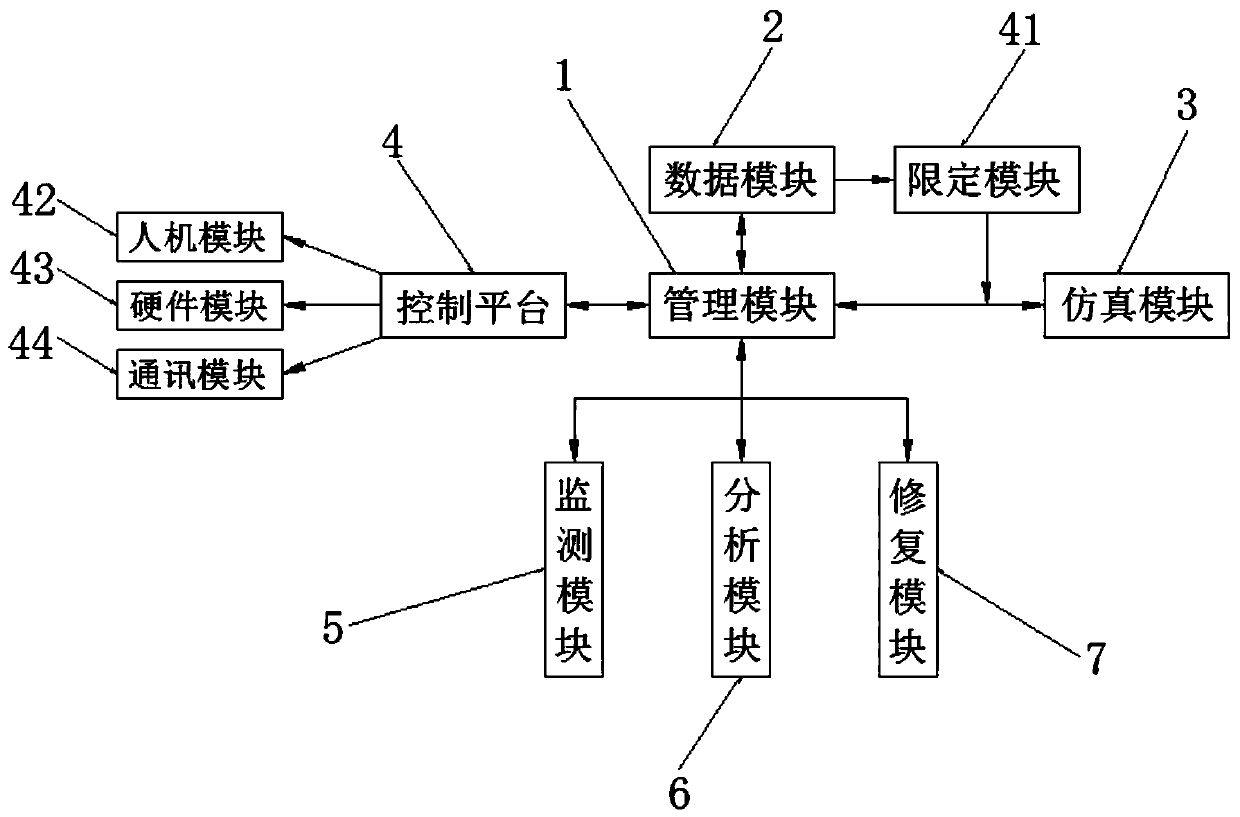

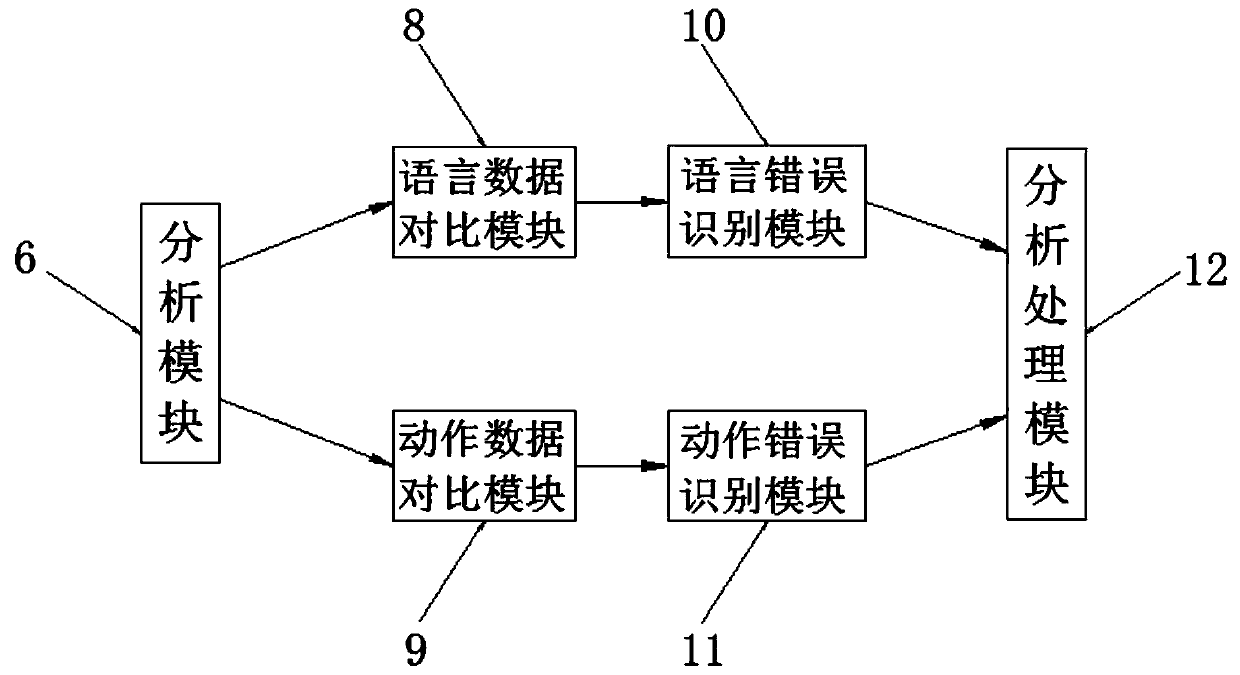

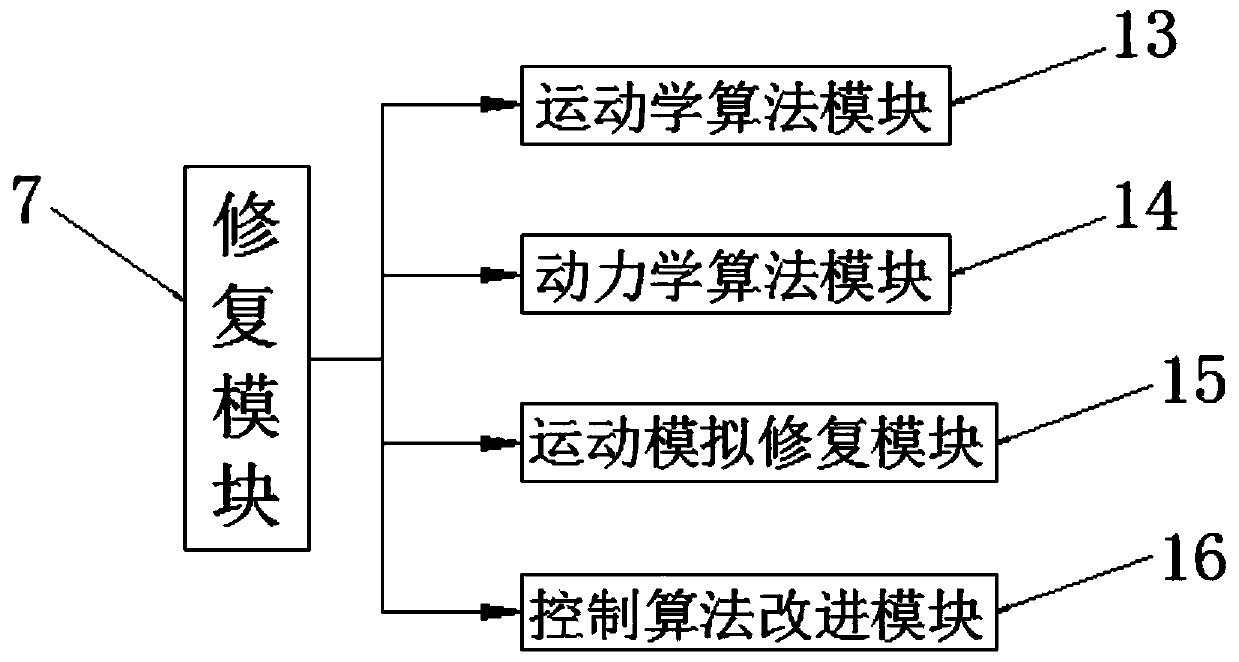

[0042] Embodiment one, such as Figure 1-3 As shown, a modular robot self-repair simulation system according to an embodiment of the present invention includes a management module 1, and the management module 1 is connected with a data module 2, a simulation module 3, a control platform 4, a monitoring module 5, an analysis module 6 and The repair module 7, through the simulation module 3, the module robot can better perform simulated action operations, so that people can use it better, and the monitoring module 5 can monitor the failure of the module robot during use. Real-time monitoring, so that it can be convenient to find problems in time, and then can facilitate better self-repair, the analysis module 6 includes a language comparison module 8 and an action comparison module 9, and the language comparison module 8 is connected with a language error recognition module 10 , the action comparison module 9 is connected with an action error identification module 11, and the la...

Embodiment 2

[0043] Embodiment two, such as Figure 4 As shown, the simulation module 3 includes an instruction receiving module 17, a language module 18, an action module 19 and an environment recognition module 20; it can make the module robot better receive instructions, thereby enabling better language and action simulation Operation, and can sense and recognize the environment while performing simulation operation, so as to better perform simulation operation.

Embodiment 3

[0044] Embodiment three, such as Figure 5As shown, the language module 18 includes a grammar module 21 and a sound module 22; through the grammar module 21 and the sound module 22, the modular robot can be closer to real people in dialogue and communication, so as to achieve better simulation effects .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com