Method for improving connection reliability of composite-material-based connecting member

A technology for composite materials and connectors, which is applied in the direction of analyzing materials, using stable torque to test material strength and strength characteristics, etc., and can solve the problem of imperfect tightening torque specification, high dispersion and complicated preparation process of composite connectors. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

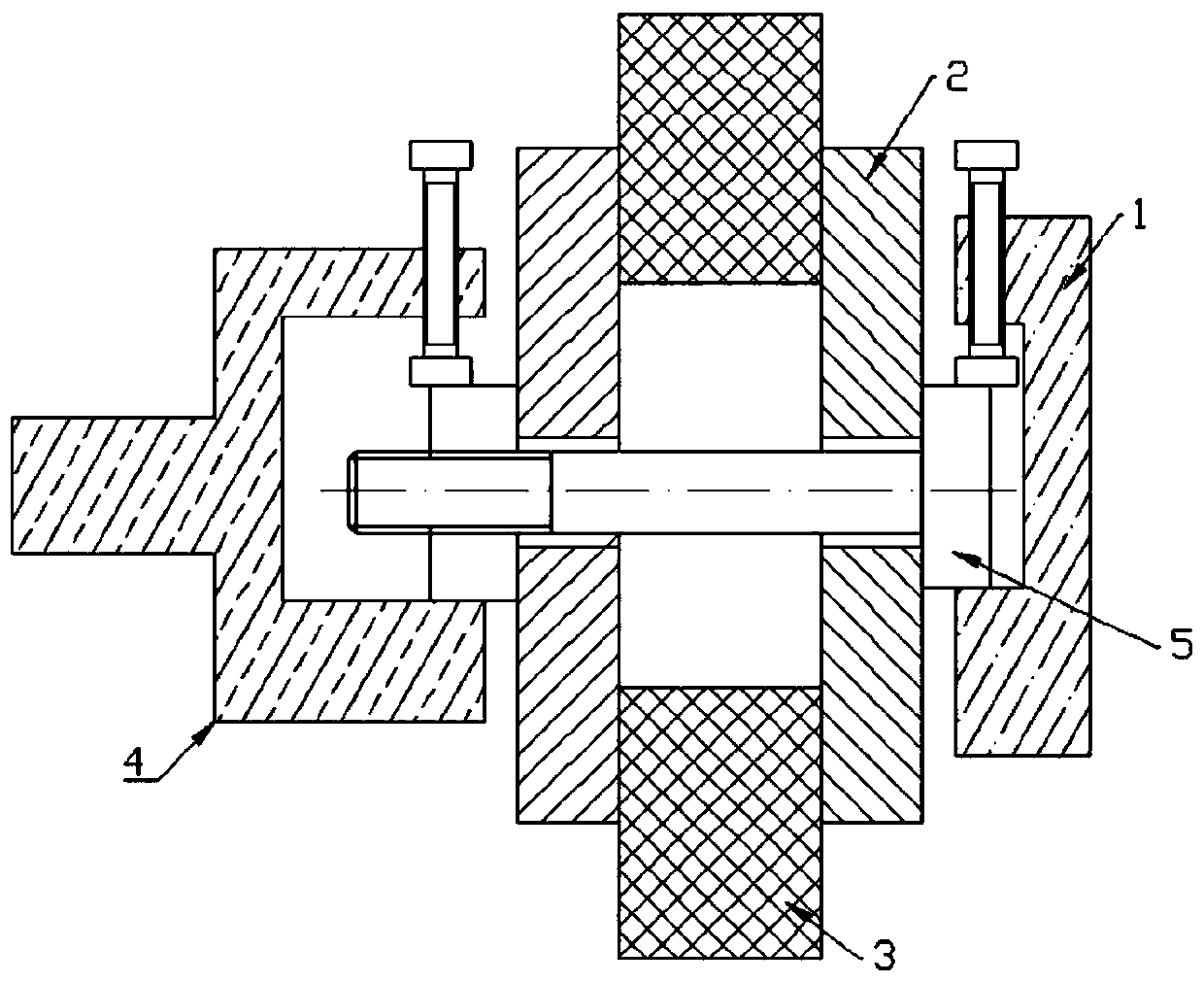

[0036] figure 1 A bolt fixing device for tightening between a connecting part and a connected part is given, including a screw fixing device 1 , a nut tightening device 4 , a connected part supporting device 3 and a strain sensor.

[0037] The screw fixing device 1 is a screw head pressing and fixing device, which is a ring structure. A threaded push rod structure is arranged at a group of opposite sides. After tightening, the screw head can be fixed and clamped. nail head form;

[0038] The nut tightening device 4 is a clamping device with an adjustable opening size. Cooperating with a torque wrench, one end of the clamping device with an adjustable opening size is to adjust the opening size through a threaded push rod, and the other end is an adapter that can be plugged with the torque wrench;

[0039] The supporting device 3 of the connected part is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com