damper

A technology of damper and damper shaft, which is applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problem that the damping force output control curve cannot maintain linearity, and achieve the effect of increasing the output adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

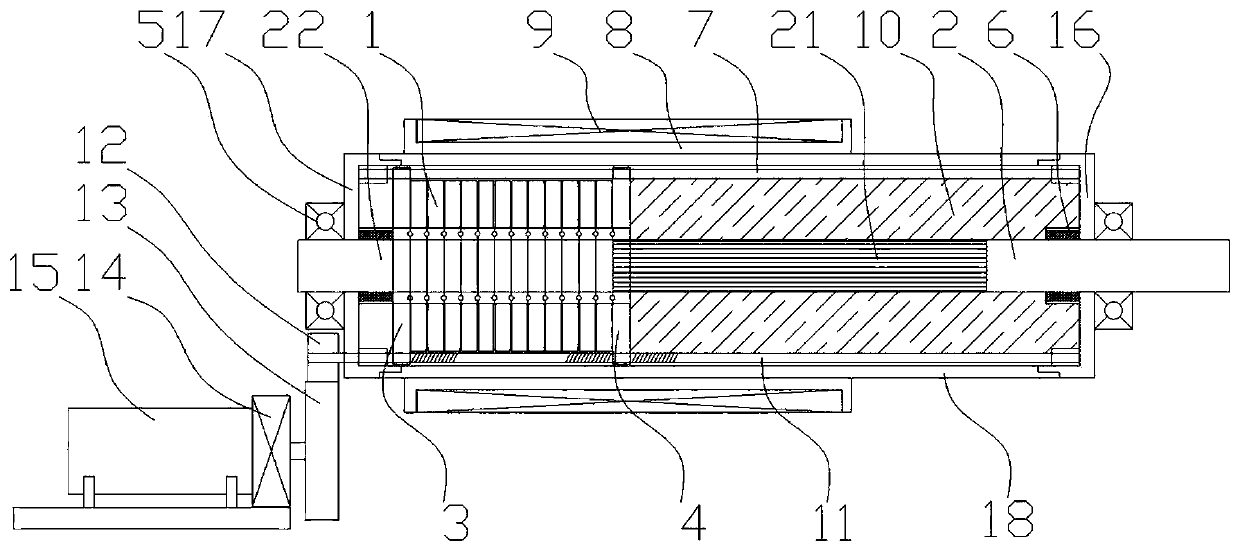

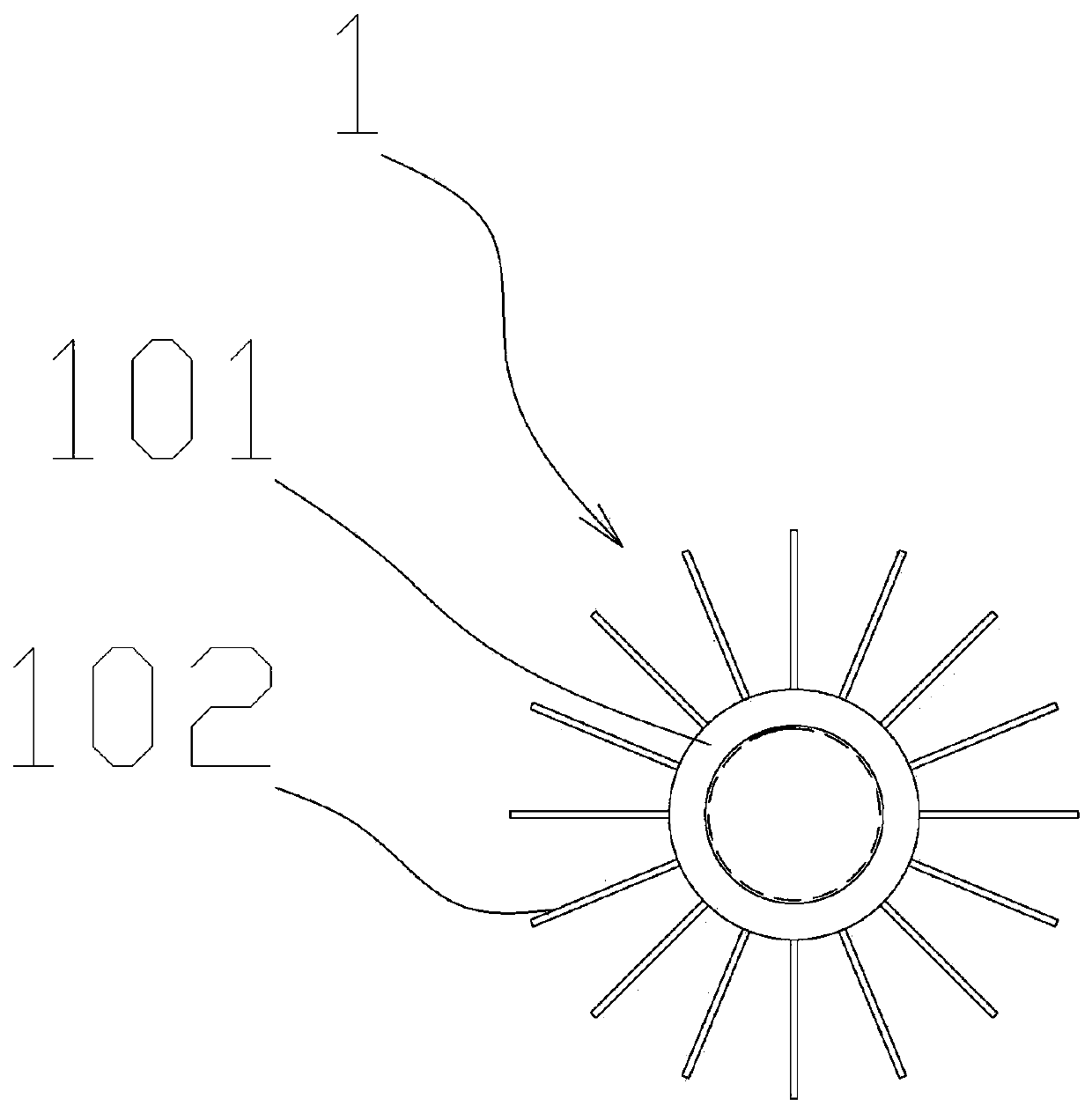

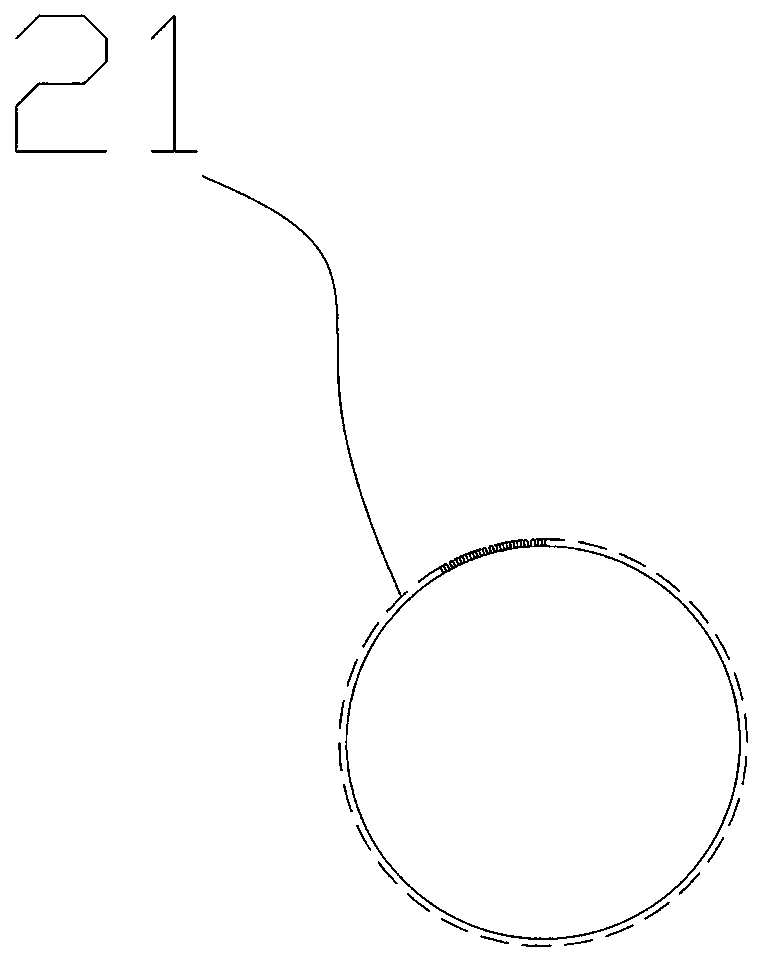

[0029] Such as Figure 1~3 Among them, a damper, a liquid medium 10 is provided in a sealed housing 18, a rotatable damping shaft 2 is provided in the sealed housing 18, the damping shaft 2 is slidingly connected with the damping plate 1, and the damping shaft 2 is provided with There are a toothed section 21 and a smooth section 22, and the outer wall of the toothed section 21 is provided with a plurality of teeth;

[0030] The damping sheet 1 includes a transmission ring 101 and a plurality of blades 102, the plurality of blades 102 are radially fixed on the outer wall of the transmission ring 101, and are uniformly distributed along the circumference, and the inner wall of the transmission ring 101 is provided with a plurality of blades that engage with the toothed segment 21. teeth;

[0031] The damping plate 1 and the toothed segment 21 of the damping shaft 2 are engaged and disengaged to adjust the magnitude of damping. With this structure, through the damping plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com