Power transmission device

A technology of power transmission and heat conduction, applied in transmission, fluid transmission, transmission control, etc., can solve problems such as lock-up clutch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

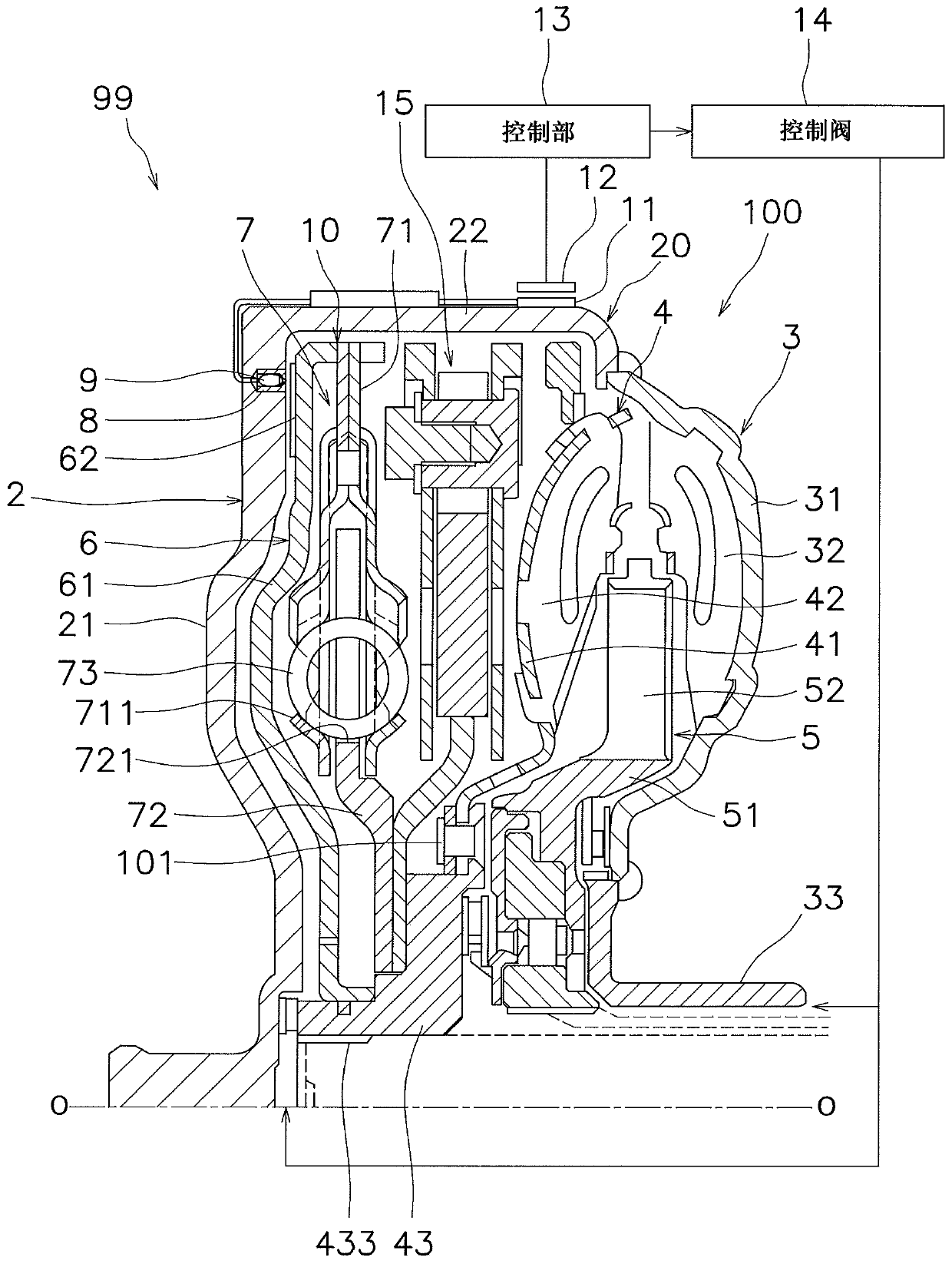

[0027] Embodiments of the power transmission device according to the present invention will be described below with reference to the drawings.

[0028] [the whole frame]

[0029] figure 1 It is a cross-sectional view of a power transmission device 99 according to an embodiment of the present invention. The power transmission device 99 includes a torque converter 100 . In the following description, "axial direction" refers to the direction in which the rotation axis O of the torque converter 100 extends. In addition, "circumferential direction" refers to the circumferential direction of a circle centering on the rotation axis O, and "radial direction" refers to the radial direction of a circle centering on the rotation axis O. The radially inner side refers to the side closer to the rotation axis O in the radial direction, and the radial outer side refers to the side away from the rotation axis O in the radial direction. In addition, although not shown, in the figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com