Double-column lifting grab handle structure and operation method for assisting automatic parking of automobiles

An operation method and a technology of a lifting mechanism, applied in lifting frames, lifting devices, etc., can solve problems such as the inability to directly apply vehicle grabbing robot equipment, and achieve the effect of improving parking efficiency and reducing psychological pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

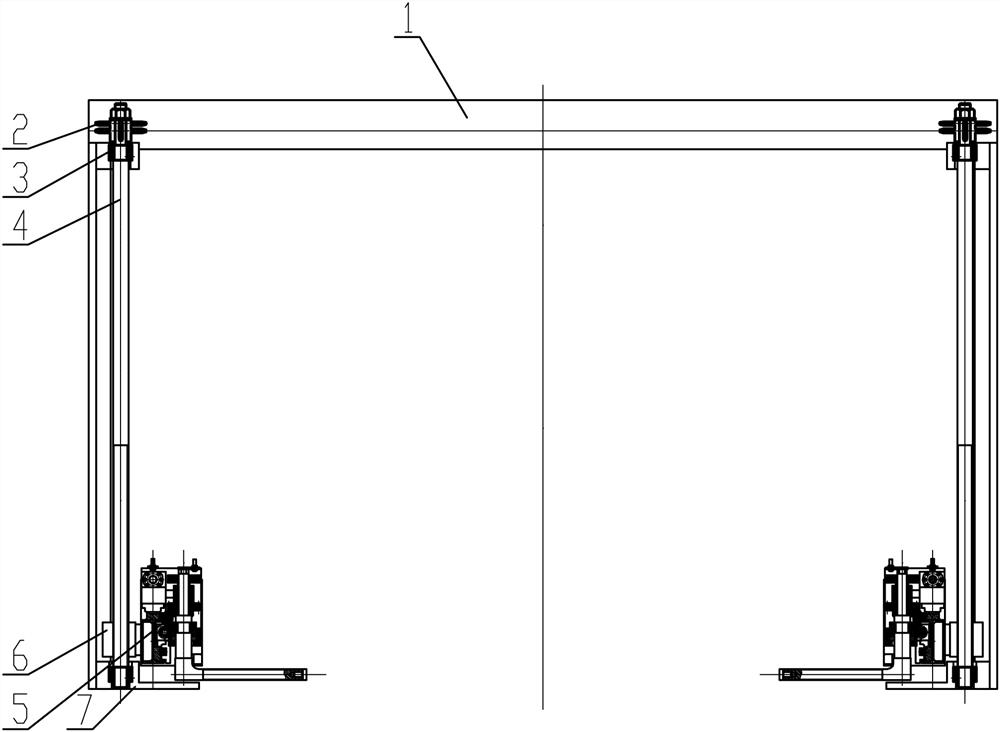

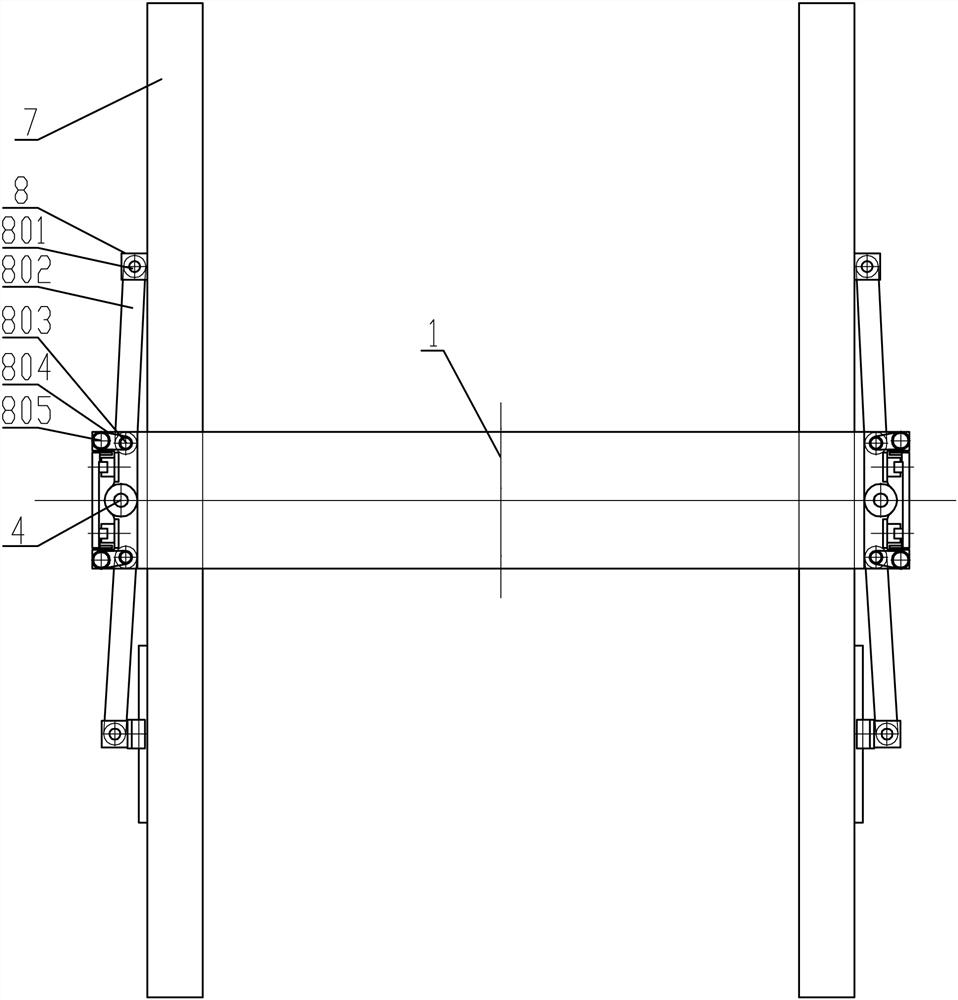

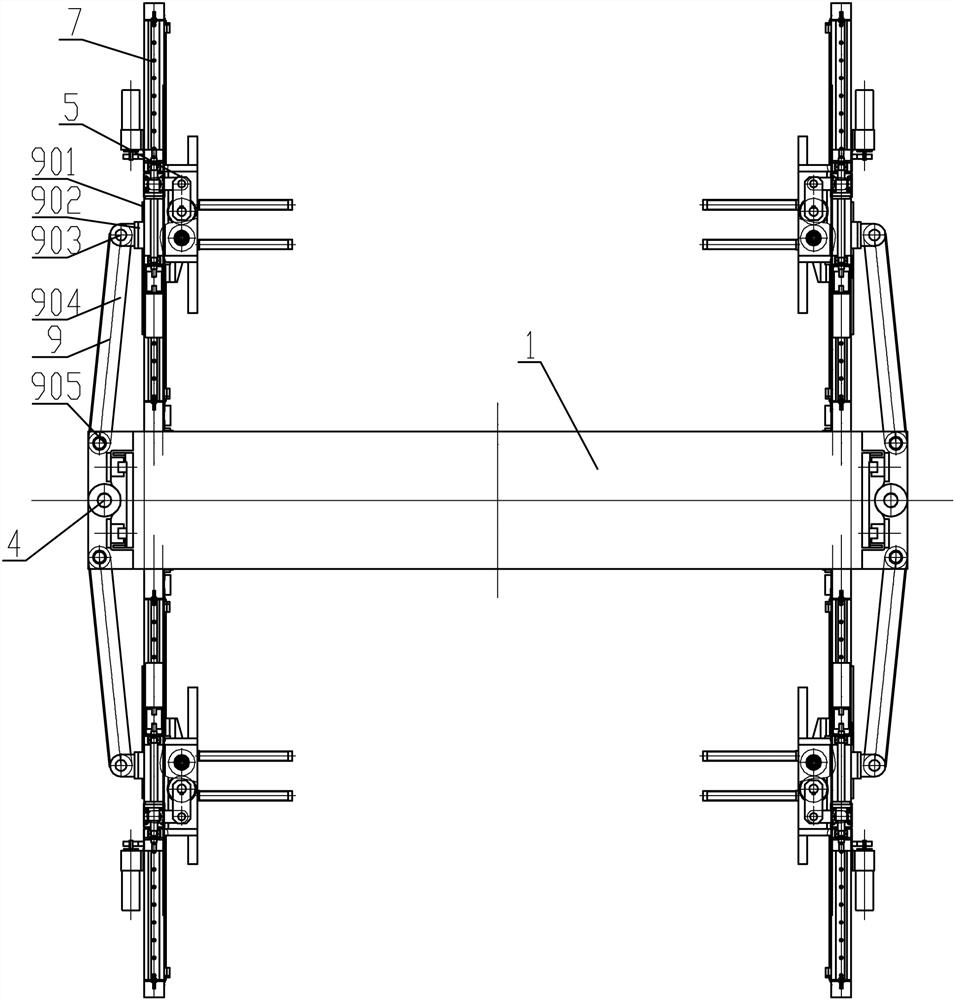

[0048] like Figure 1-9 As shown, the double-column lifting grab structure for assisting automatic parking of automobiles includes a top hoisting beam 1, and swing frames 7 are symmetrically installed at both ends of the bottom of the top hoisting beam 1. 10 is a double-column vertical lifting mechanism for lifting. The two-column vertical lifting mechanism is equipped with a grabbing device 5 for grabbing the car 10, and the sides of the swing frame 7 are respectively symmetrically installed for adjusting A swing adjustment mechanism for its swing angle. By adopting the above structure, the double-column lifting gripper structure can be used for automatic grabbing, lifting and straightening of cars placed at any angle, and then assists the AGV trolley device to complete the automatic storage and parking of cars, improving the parking efficiency of cars , Alleviate the psychological pressure of the driver to park the car. During the parking process, the driver only needs to ...

Embodiment 2

[0057] The operation method of any one of the double-column lifting grab structure for assisting the automatic parking of automobiles includes the following steps:

[0058] Step 1, according to the angle at which the car 10 is placed, the angle of the swing frame 7 is automatically adjusted by the swing adjustment mechanism, so that the car grabbing device 5 is arranged along a direction parallel to the center line of the car 10;

[0059] Step 2, after the angle adjustment is completed, start the car grabbing device 5, and clamp the tires of the car 10 through the first car clamping lever 518 and the second car clamping bar 519 of the car grabbing device 5, and then complete the grabbing of the car 10 ;

[0060] Step 3, start the double-column vertical lifting mechanism, drive the lifting nut seat 6 through the lifting screw 4 of the double-column vertical lifting mechanism, and then use the lifting nut seat 6 to synchronize the car grabbing device 5 and the car 10 on its top....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com