Flexible connector arranged between ultra-large offshore floating platform modules and butt joint method

A flexible connector, floating platform technology, used in floating buildings, ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

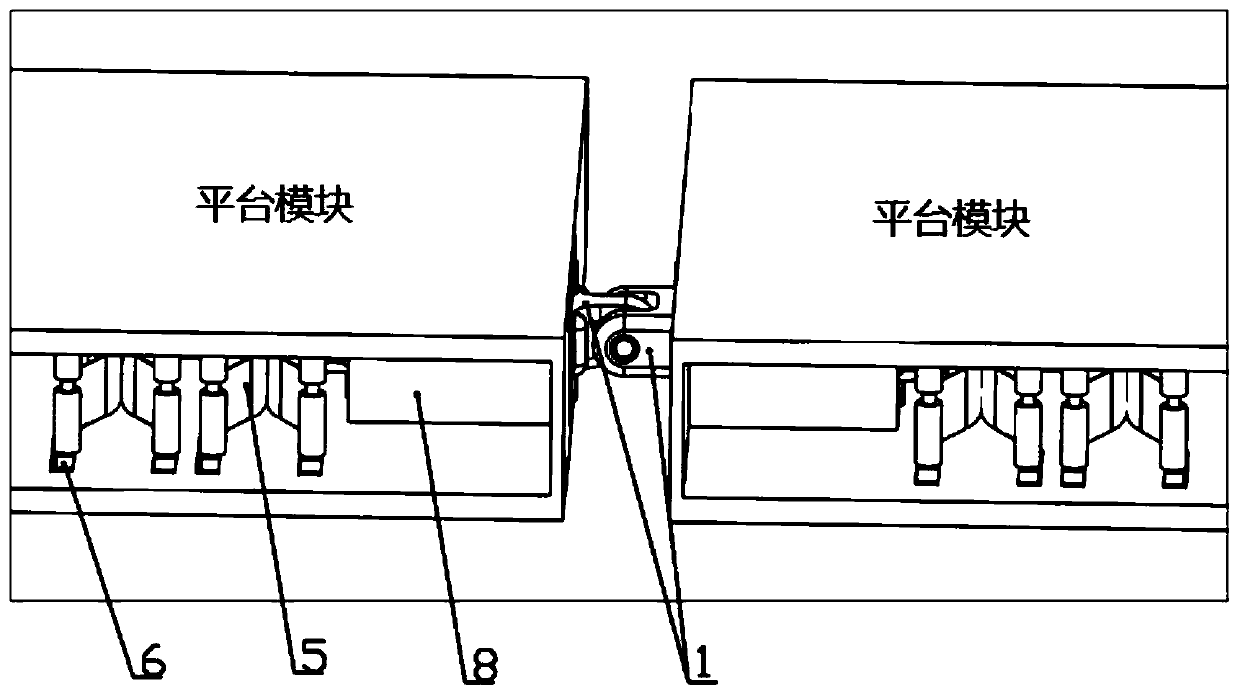

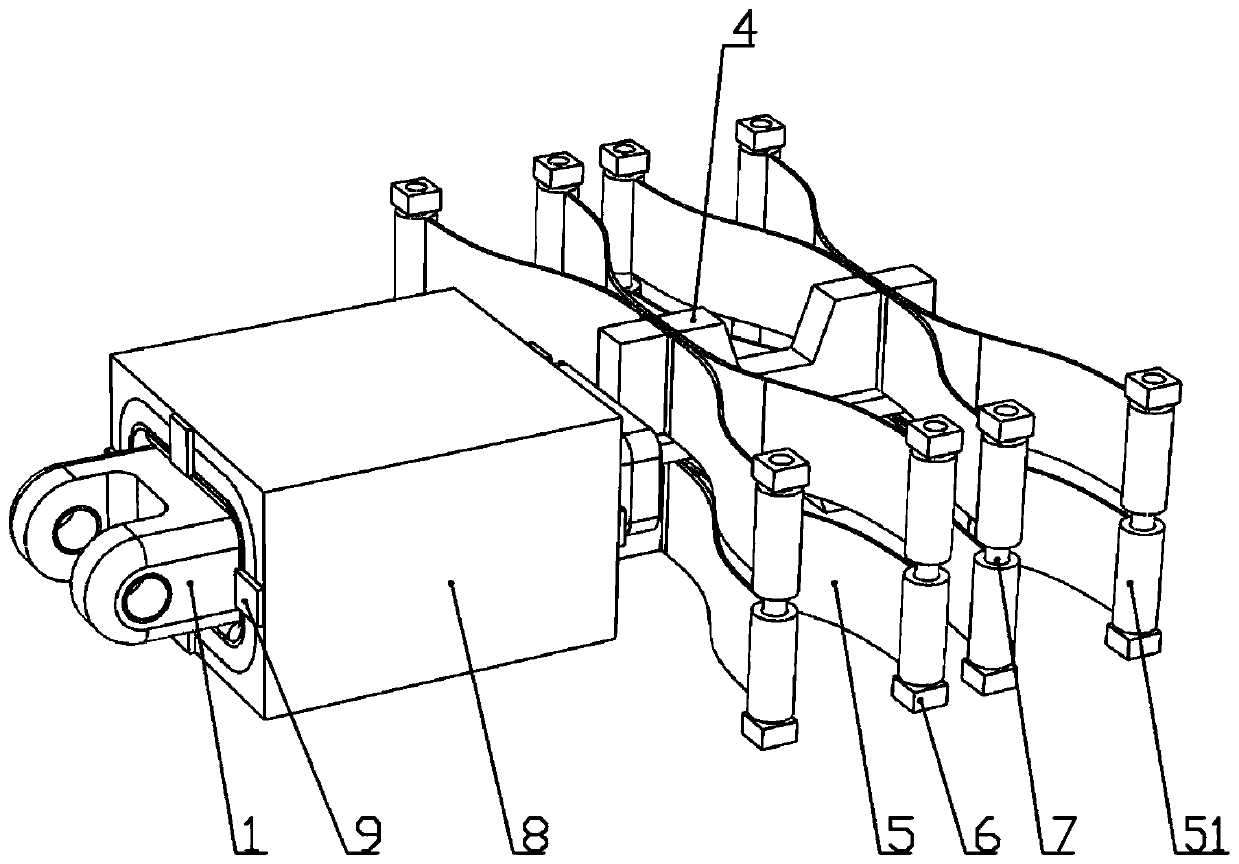

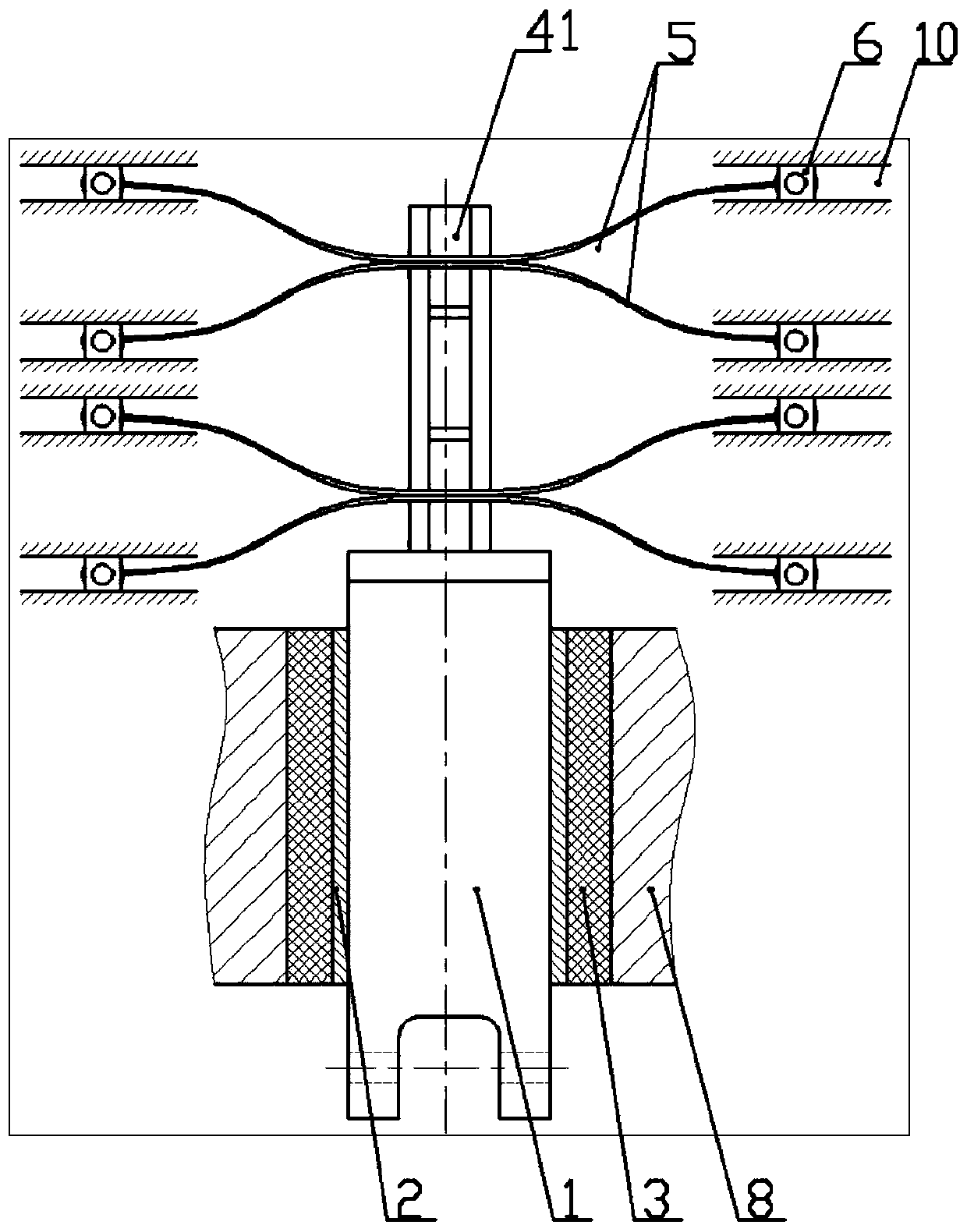

[0028] Such as Figure 1 to Figure 6 As shown, the flexible connector between modules of the ultra-large offshore floating platform disclosed in this embodiment includes a sliding column 1, a sliding sleeve 2, a rubber sleeve 3, a support 4, a spring steel plate 5, a slider 6, and a connecting shaft 7. The fixed seat 8 and the sliding sleeve block 9 are especially suitable for the docking of the platform module as an inner hollow square body.

[0029] In this embodiment, the sliding column 1 is a solid square column, the sliding sleeve 2 is a matching square tube, and the rubber sleeve 3 is elastically deformed when it is placed outside the sliding sleeve 2, so that the inner wall of the rubber sleeve 3 and the outer wall of the sliding sleeve 2 are in close contact. together, and the inner and outer walls of the rubber sleeve 3 are vulcanized. The rear end of the strut 1 has a threaded hole for connecting the support. The sliding column in other embodiments can also adopt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com