Building concrete damage detection equipment

A technology for damage detection and concrete, applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of small size, troublesome and time-consuming, and difficult to find the sheath, so as to avoid difficult to find Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

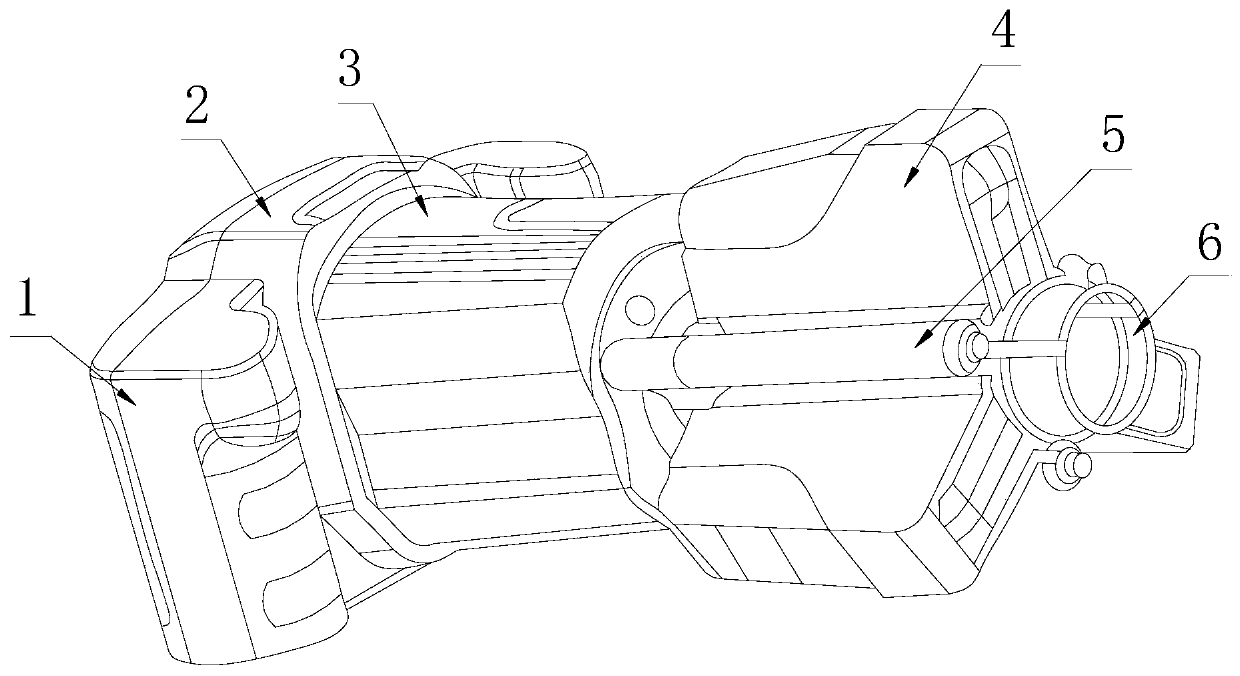

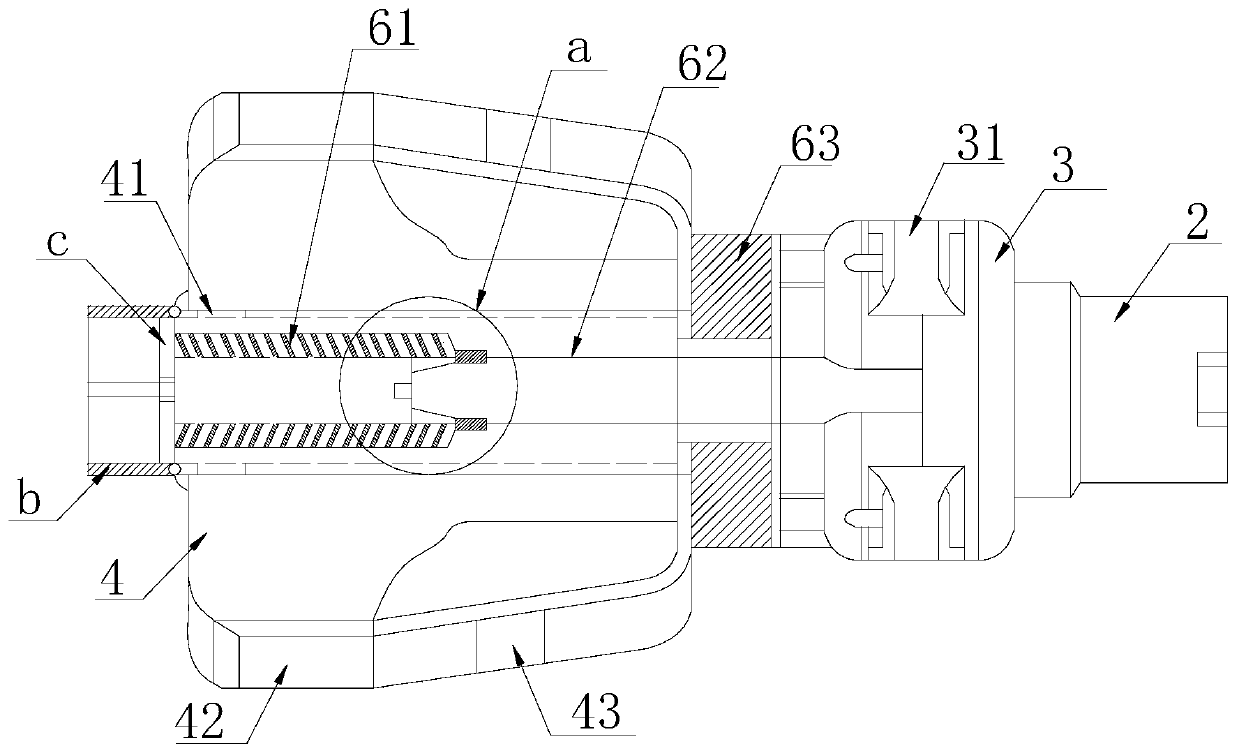

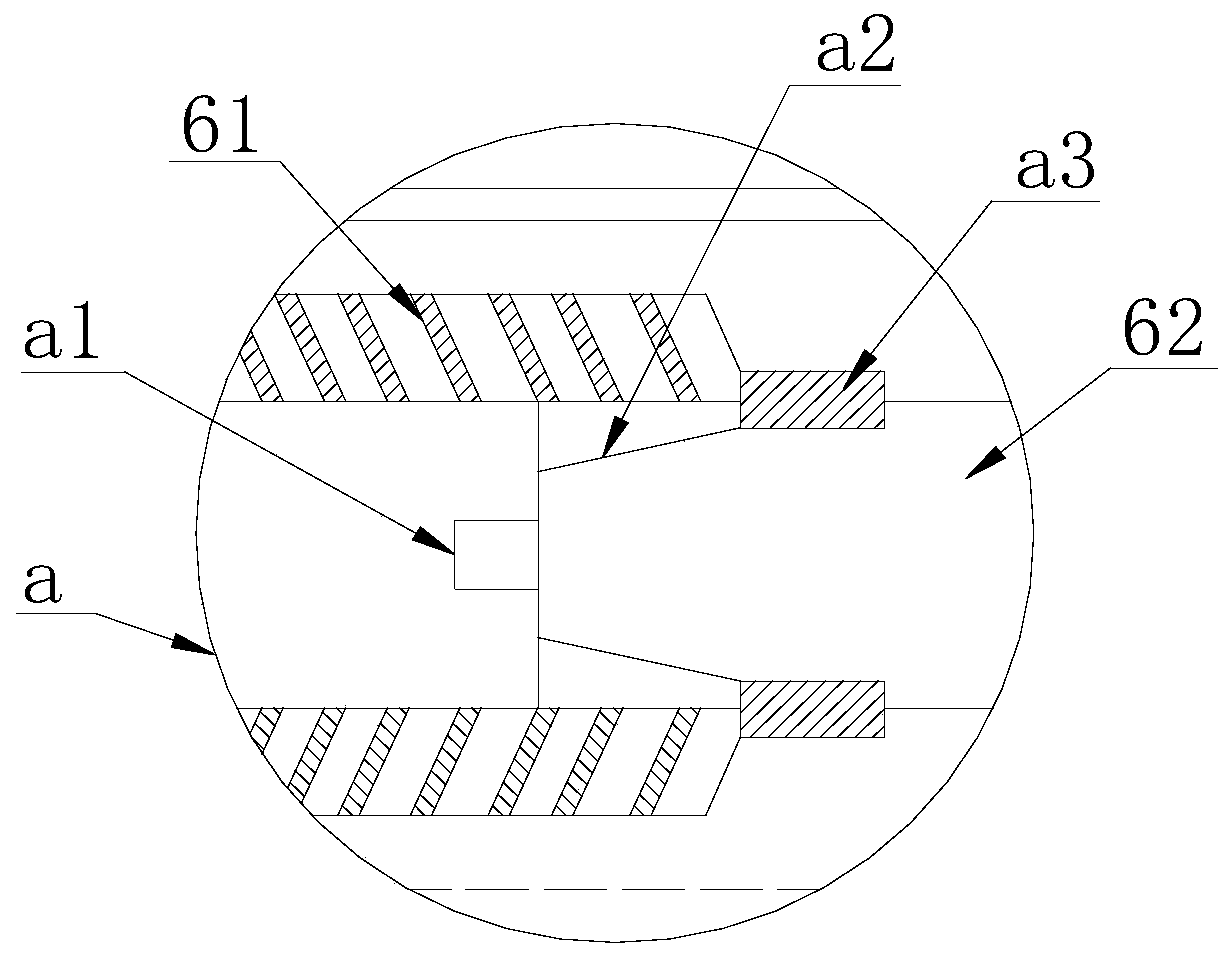

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of building concrete damage detection equipment, and its structure comprises handle 1, data collector 2, reduction box 3, protective shell 4, support bar 5, three-jaw chuck 6, and the data collector 2 The outer surface is fixed with a handle 1, the data collector 2 is electrically connected to the reduction box 3, the three-jaw chuck 6 is controlled by the reduction box 3, and the three-jaw chuck 6 is matched inside the protective shell 4 , a support rod 5 is fixed in the crack of the protective shell 4, a rotating sleeve 63 is movably fitted at the junction of the reduction box 3 and the three-jaw chuck 6, and the main screw is respectively installed in the level of the three-jaw head 6 62 and the auxiliary screw 61, a locking mechanism a is matched at the contact port of the auxiliary screw 61 and the main screw 62, the end of the auxiliary screw 61 relative to the main screw 62 is fixed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com