Labor-saving touch trigger lock mechanism

A lock mechanism and touch technology, which is applied to building locks, building structures, locks with spring bolts, etc. Large, high manufacturing cost of automatic door locks, to achieve the effect of flexible and light unlocking operation, reduced matching accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

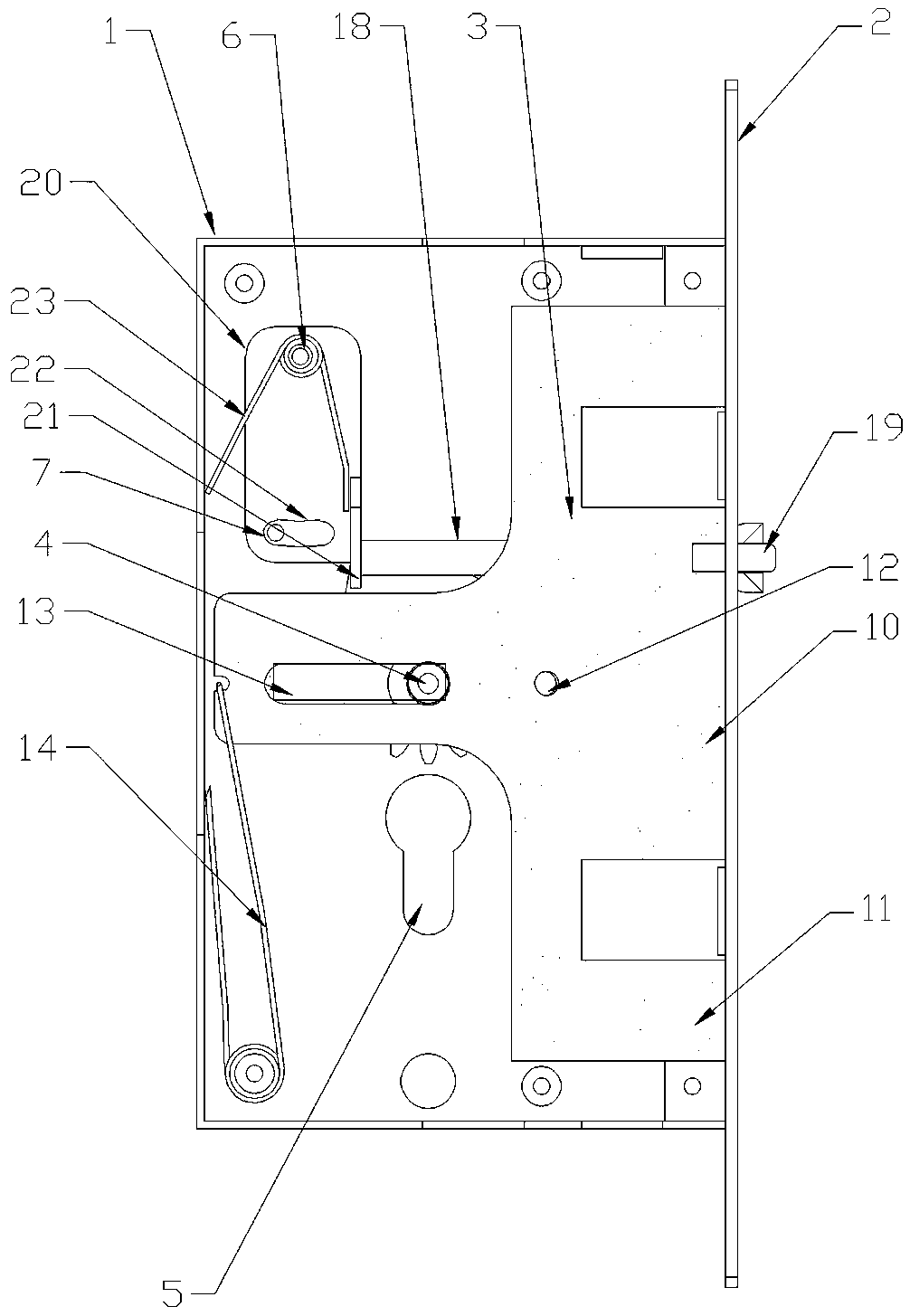

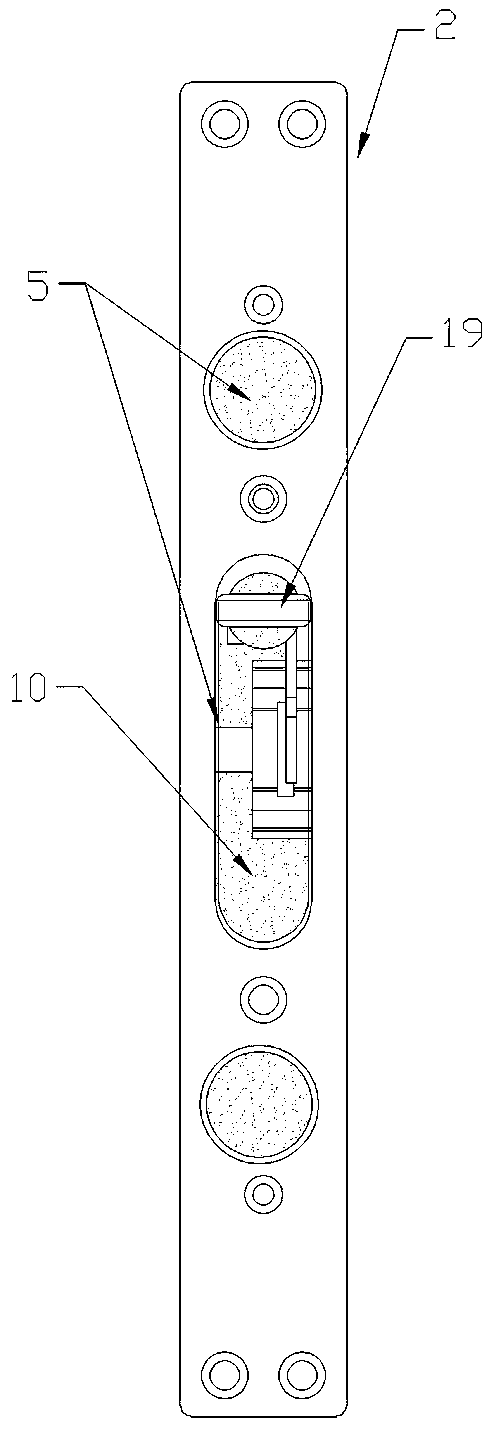

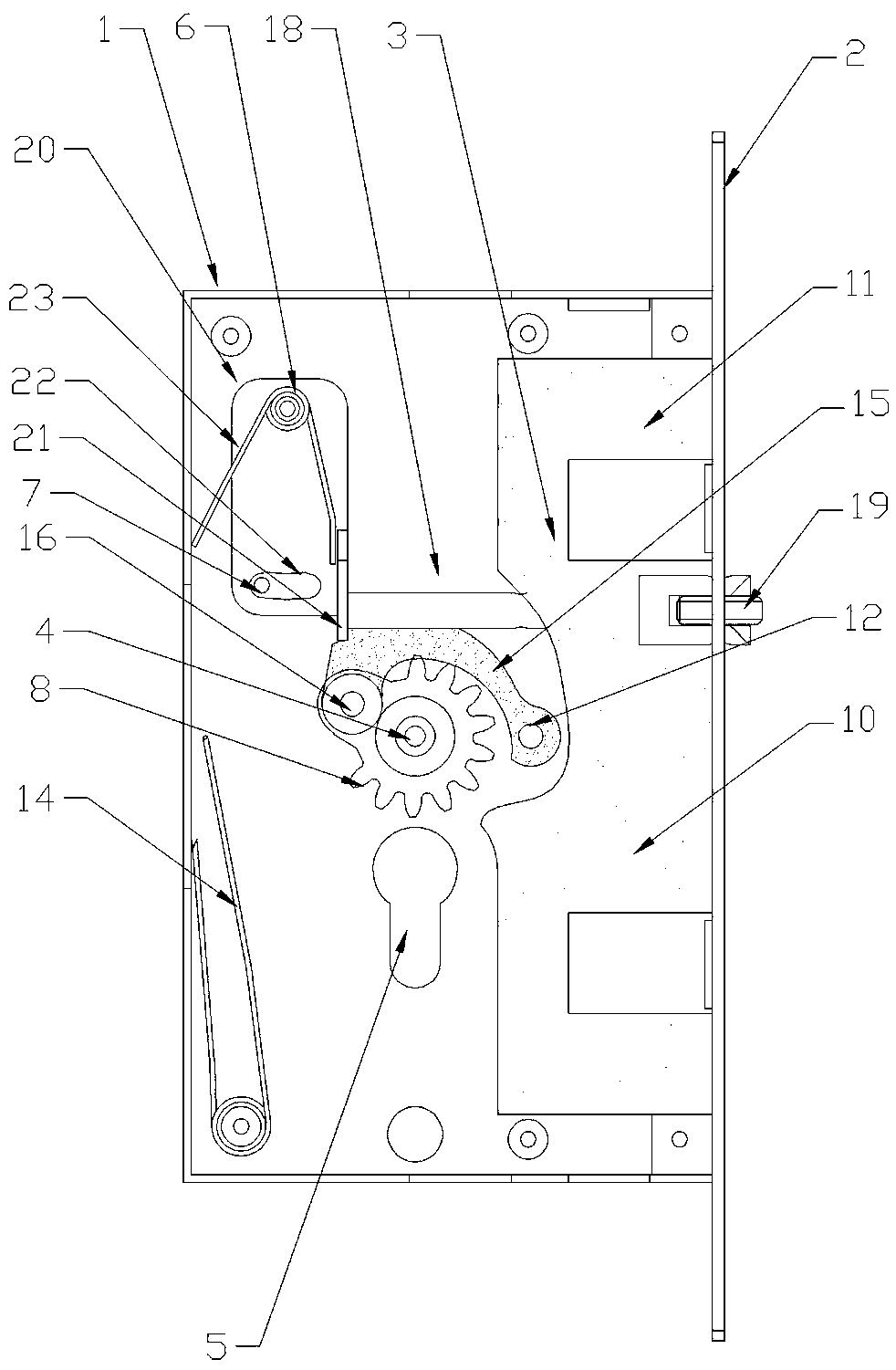

[0018] In order to more clearly illustrate the specific implementation of the present invention or the technical solutions in the prior art, the following will briefly introduce the drawings that need to be used in the specific implementation. Throughout the drawings, similar components or parts are generally identified by similar reference numerals. In the drawings, each device or part is not necessarily drawn in actual scale.

[0019] Figure 1 to Figure 5 As shown, it is a specific embodiment of the automatic lock triggered by the contact of the oblique tongue of the gear lock cylinder of the present invention. The present invention provides a labor-saving contact trigger lock mechanism, which includes a lock housing 1, a lock body mounting plate 2, and a lock tongue linkage Component 3 and the lock tongue trigger component; it is characterized in that: the inside of the lock housing 1 is provided with a guide rod 4, a lock cylinder installation hole 5, a mounting shaft 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com