Defective product control warehouse and defective product control method

A quality control and defective technology, which is applied in the defective product control warehouse of printed circuit boards and the field of defective product control using the defective product control warehouse, can solve the problems of mixed storage of defective products, easy to be taken out of defective products at will, and prevent mix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

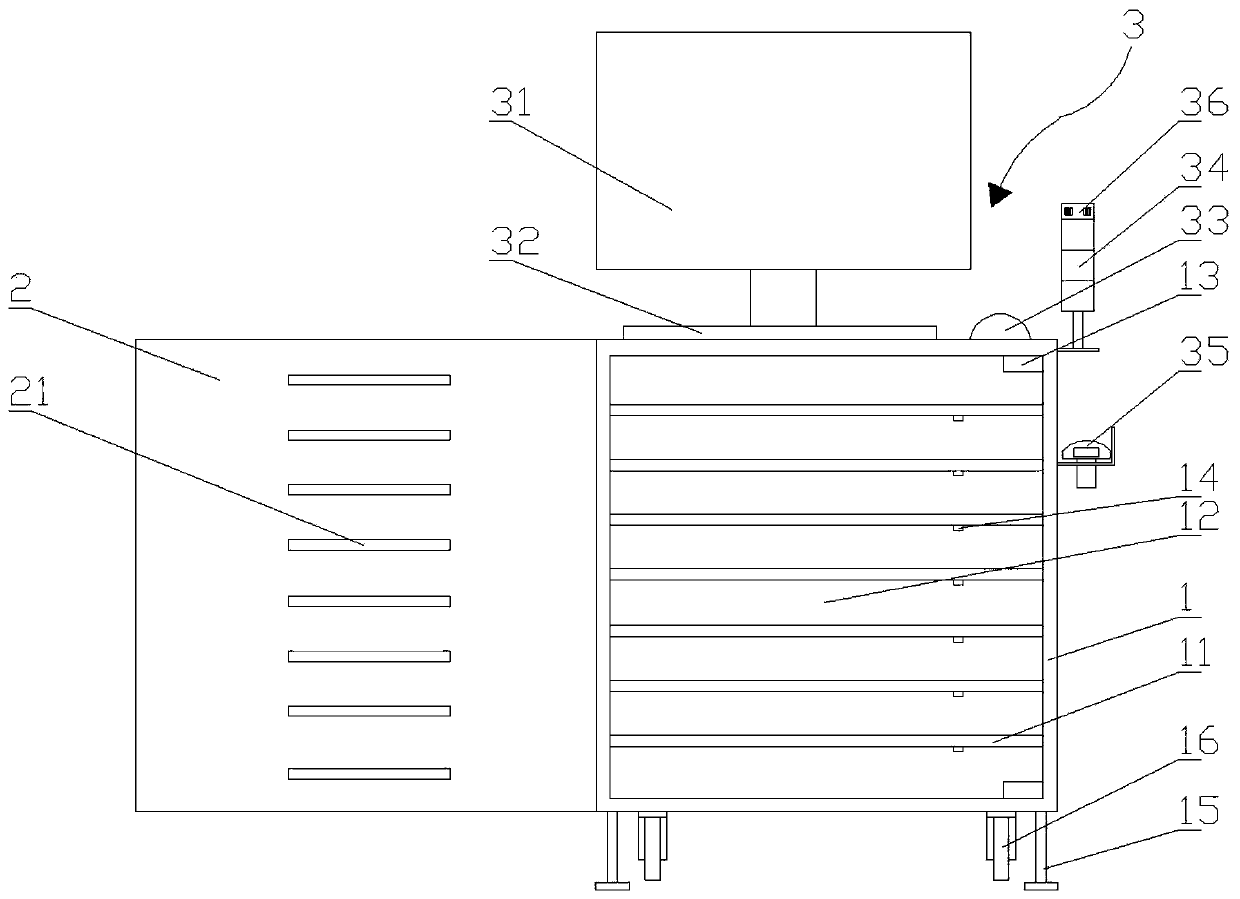

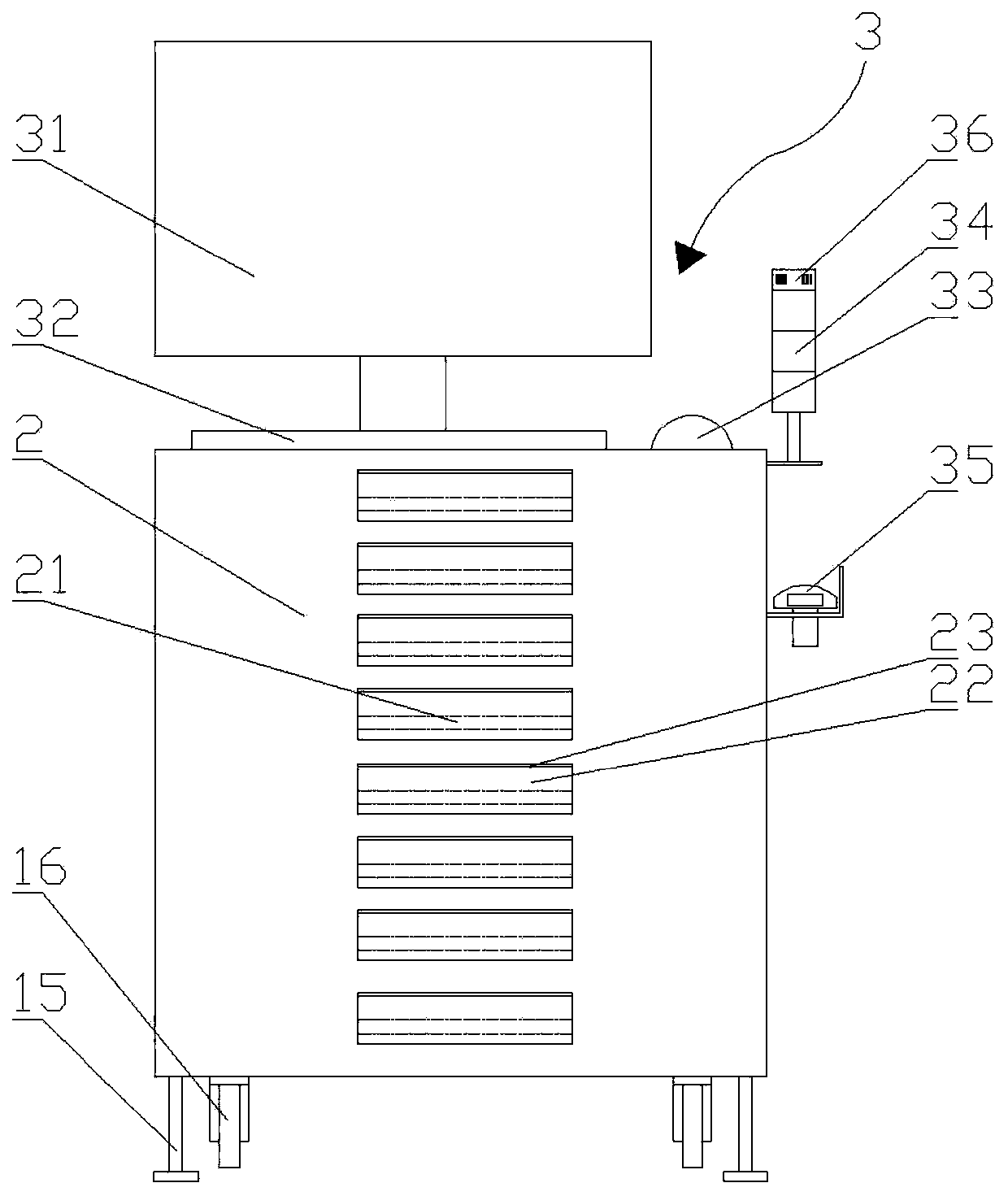

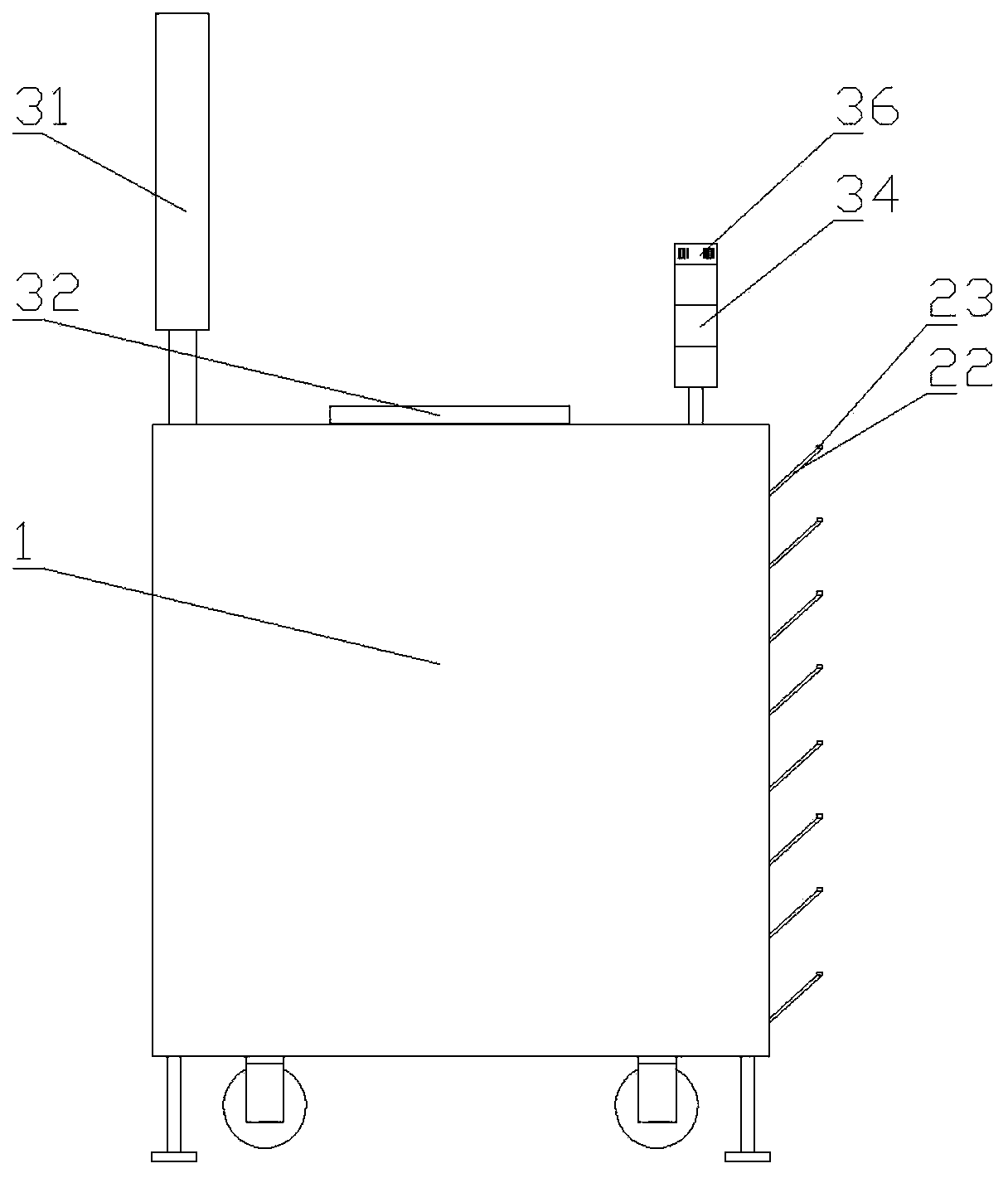

[0027] The technical scheme of the present invention will be further explained below in conjunction with the drawings:

[0028] The up and down direction in the present invention refers to figure 1 In the up and down direction, the outside in the present invention refers to image 3 Right in the middle.

[0029] Such as Figure 1-3 As shown, the present invention provides a defective product control warehouse, including: a box body 1, a box door 2, a control center 3, wherein the box body 1 is a frame structure, and the bottom of the box body 1 is provided with a roller 16 and a foot 15, in The external force pushes the lower box 1 to move along the production line through the roller 16. After moving in place, raise the foot 15 to fix the box 1 on the ground; the box door 2 is rotatably connected to the box 1, and the box door 2 has an opening State and closed state. Generally, the door 2 is locked on the box 1 by an electronic lock 13 and is in a normally closed state; the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com