A ship repair and maintenance system

A maintenance system and ship technology, applied in the direction of slipway, dry dock, ship construction, etc., can solve the problem of difficult maintenance of the platform, and achieve the effect of improving the relative contact stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached figure 1 - attached Figure 4 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

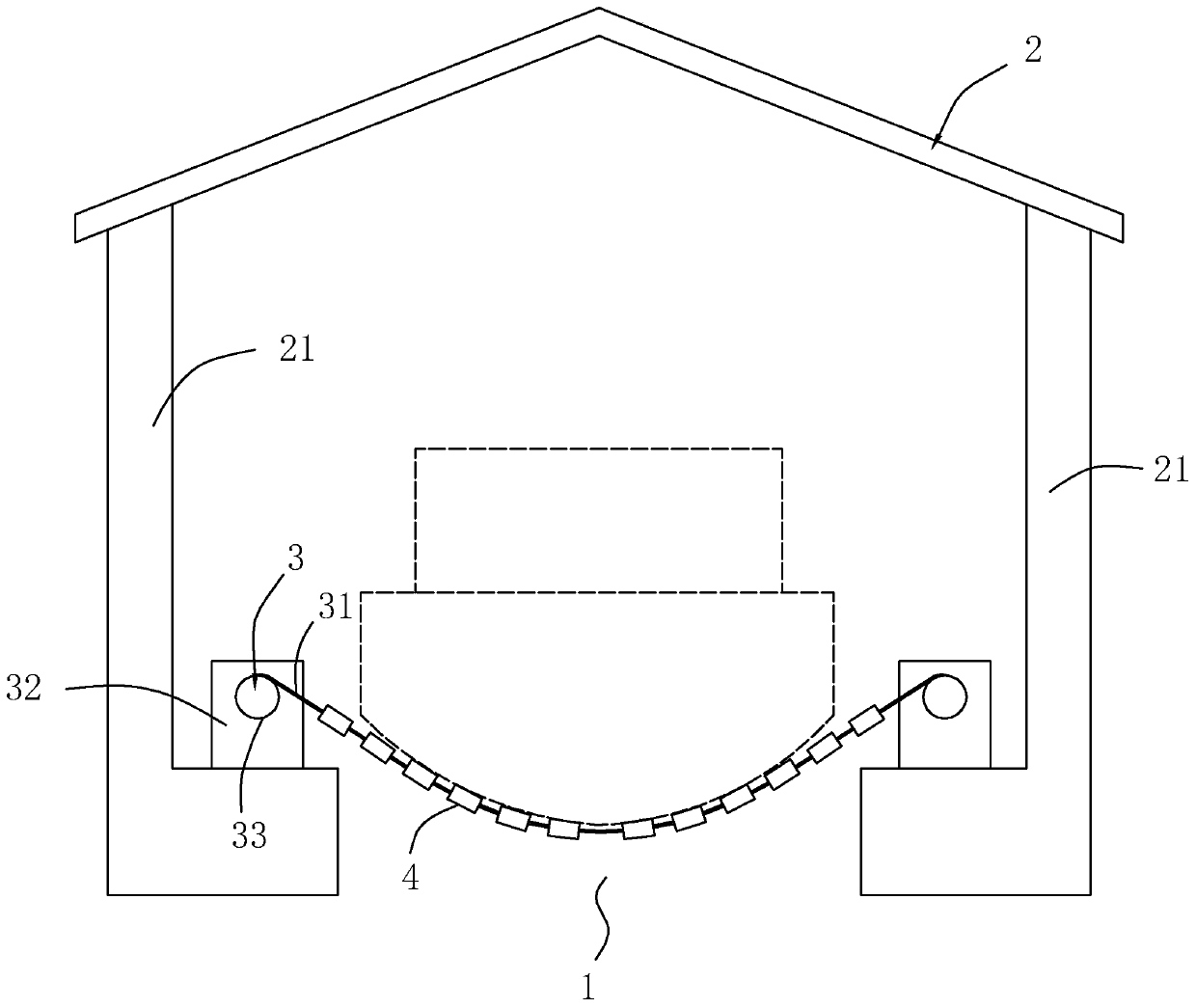

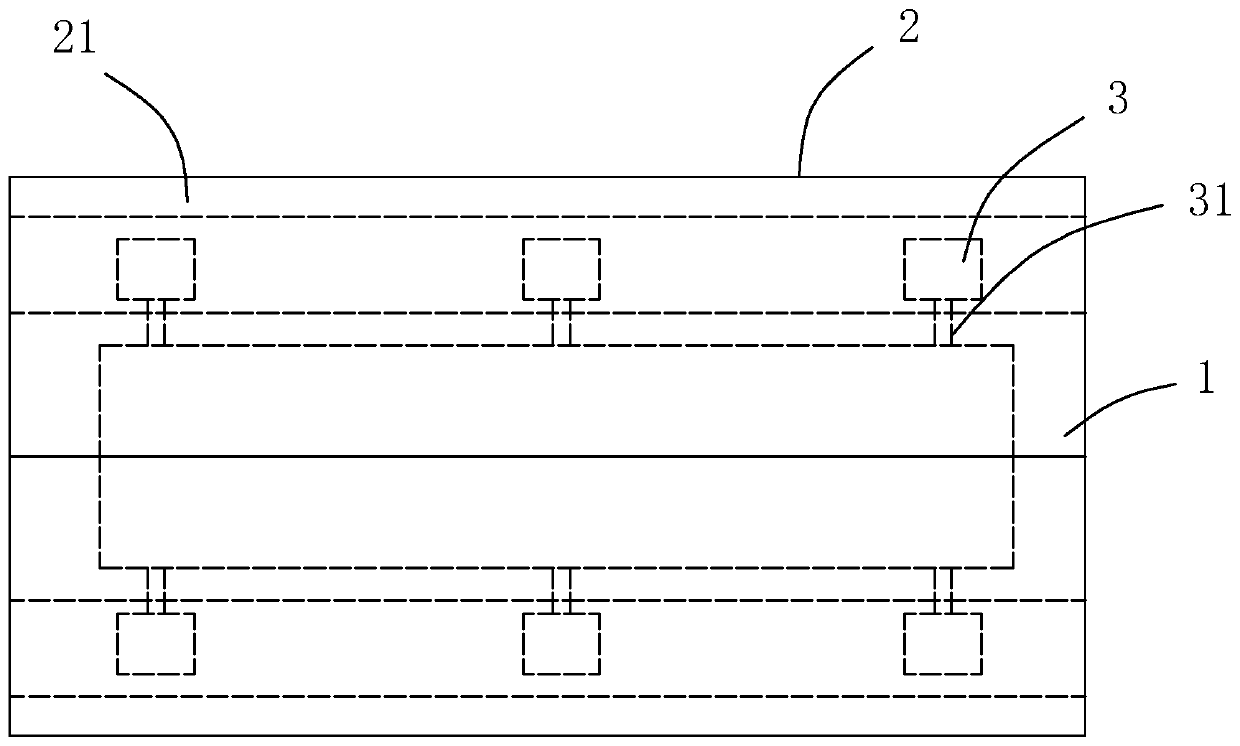

[0037] A ship repair and maintenance system, comprising a maintenance frame body 2, the maintenance frame body 2 includes maintenance columns 21 located on the left and right sides of a navigation channel 1, and upper ends of the maintenance columns 21 on both sides are provided with upper sheds.

[0038] A navigation channel 1 is arranged between the maintenance columns 21 on both sides. The navigation channel 1 runs through the maintenance frame body 2 front and rear. The body is located directly above the ship to be repaired, and the ship to be repaired moves into or out of the maintenance frame body 2 along the penetrating direction of the navigation passage 1.

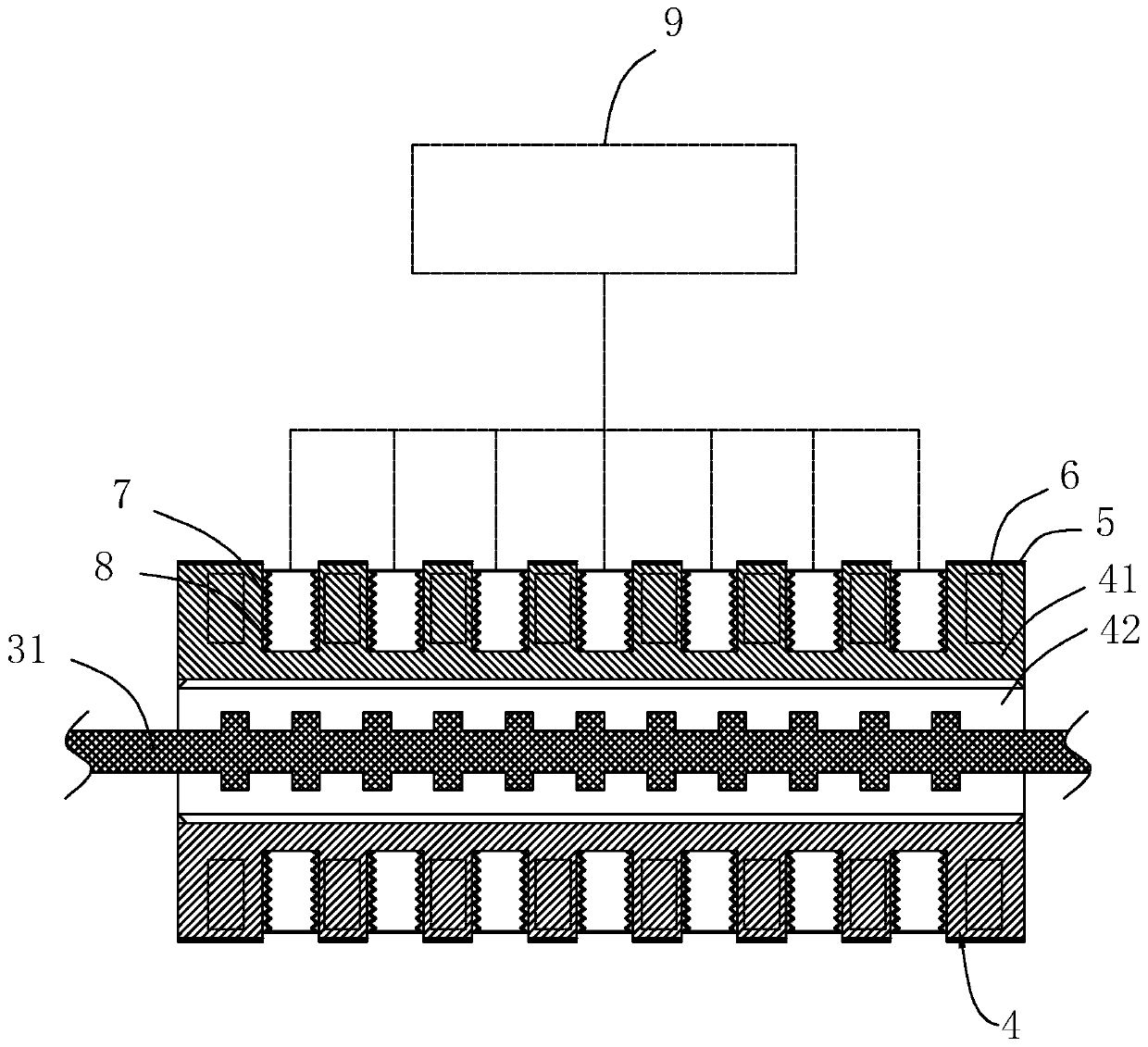

[0039] At least two groups of lifting components 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com