Shelf shelving plate structure

A shelf and shelf technology, applied in the field of commercial facilities, can solve problems such as consumption of fasteners, loosening, and the influence of surface coating process, so as to improve processing efficiency, ensure service life, and avoid fasteners and spot welding electrode materials. the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

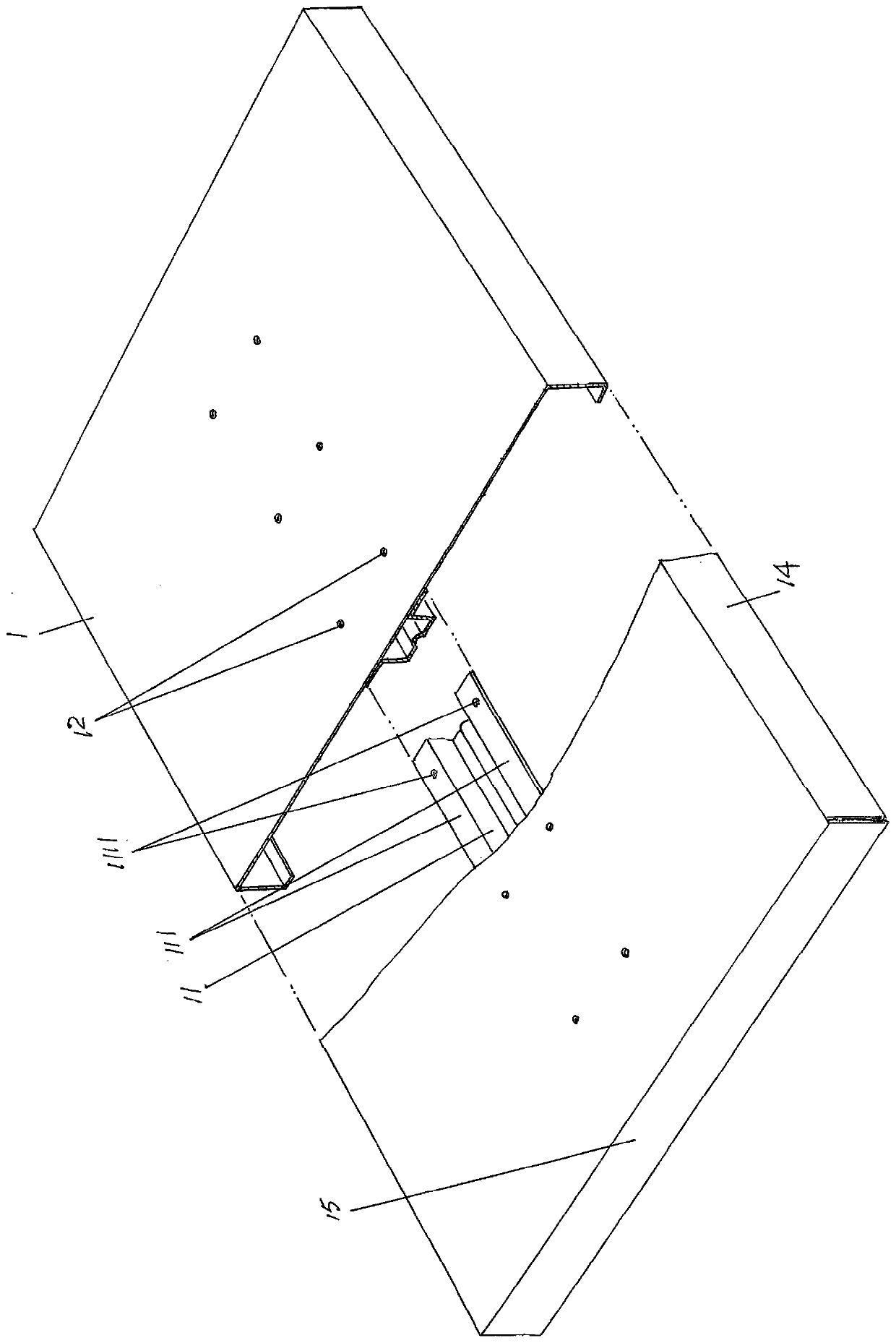

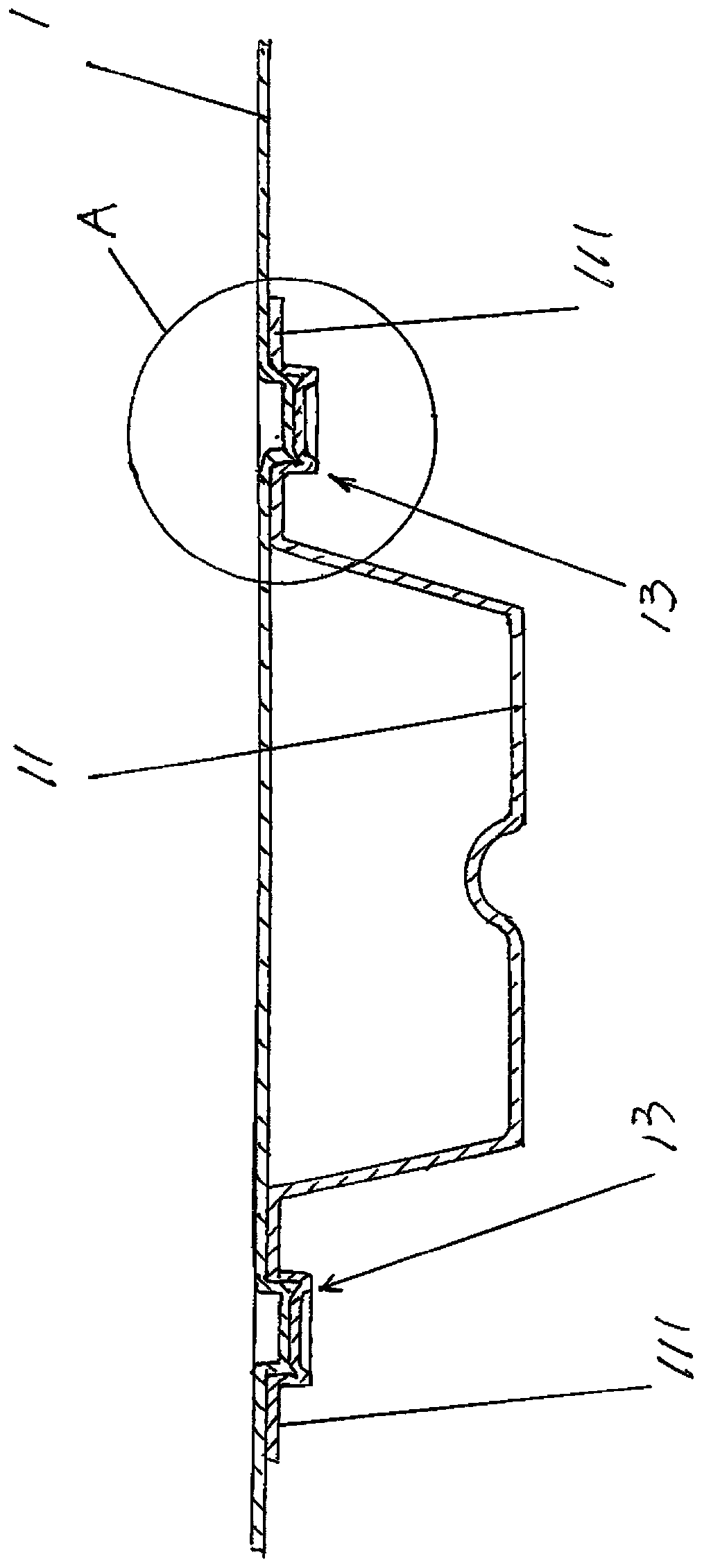

[0028] See Figure 1 to Figure 3 , shows a shelf body 1, in the use state of the shelf body 1, a reinforcing rib 11 is provided on the downward side, and the upper side and the other side of the reinforcing rib 11 in the length direction Each of them constitutes a reinforcing rib connecting wing 111, and the reinforcing rib connecting wing 111 is in contact with the downward facing side surface of the shelf body 1 in use, on the aforementioned shelf body 1 and corresponding to the aforementioned reinforcing rib The length direction of the bar connecting wings 111 is formed with shelf body joint points 12 (also called "shelf body joint parts", hereinafter the same) at intervals, and on the rib connecting wings 111 and corresponding to the aforementioned shelf The position of the body joint 12 constitutes a connecting wing joint 1111 (also called "connecting wing joint", hereinafter the same).

[0029] As the technical gist of the technical solution provided by the present inve...

Embodiment 2

[0036] See Figure 5 ,Depend on Figure 5 As shown, the two ends of the long edge flange 14 of the aforementioned shelf body are respectively provided with mounting and fixing holes 141 for the long edge flange of the shelf body; The adjustment bolt hole 151 is installed, and the installation adjustment bolt hole 151 of the shelf body is an oval hole opened horizontally.

[0037] See Figure 6 ,exist Figure 6 The shelf column triangular support plate 33 fixed on the shelf column 3 of the angle steel shelf is shown in the figure. The shelf shelf body 1 of the present invention is installed as required by the bolts corresponding to the long side edge flanges of the shelf body 141 and the corresponding bolts. Install the bolts in the adjusting bolt holes 151 on the shelf body and Figure 6 The angle steel shelves (ie storage shelves) shown are fixed.

Embodiment 3

[0039] See Figure 7 Since the length of the shelf body 1 is relatively long, the aforementioned reinforcing ribs 11 are arranged in a spaced state on the shelf body 1 facing downwards in a state parallel to the short side direction of the aforementioned shelf body 1. On one side, the longitudinal connection or front-to-back connection of the shelf shelf body 1 and the aforementioned shelf insert 2 in Embodiment 1 is changed to a horizontal connection or left-right connection. All the other are the same as the description to embodiment 1.

[0040] See Figure 8 , showing the column beam 32 of the shelf column 3, Figure 7 The illustrated shelf body 1 rests on a post beam 32 . All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com