CFD-based heavy metal wastewater sulfuration precipitation reactor optimization method

A technology of sulfide precipitation and optimization method, applied in the direction of chemical process analysis/design, complex mathematical operations, etc., can solve the problems of materials, time waste, can not meet the analysis requirements of reactor design optimization, etc., to achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

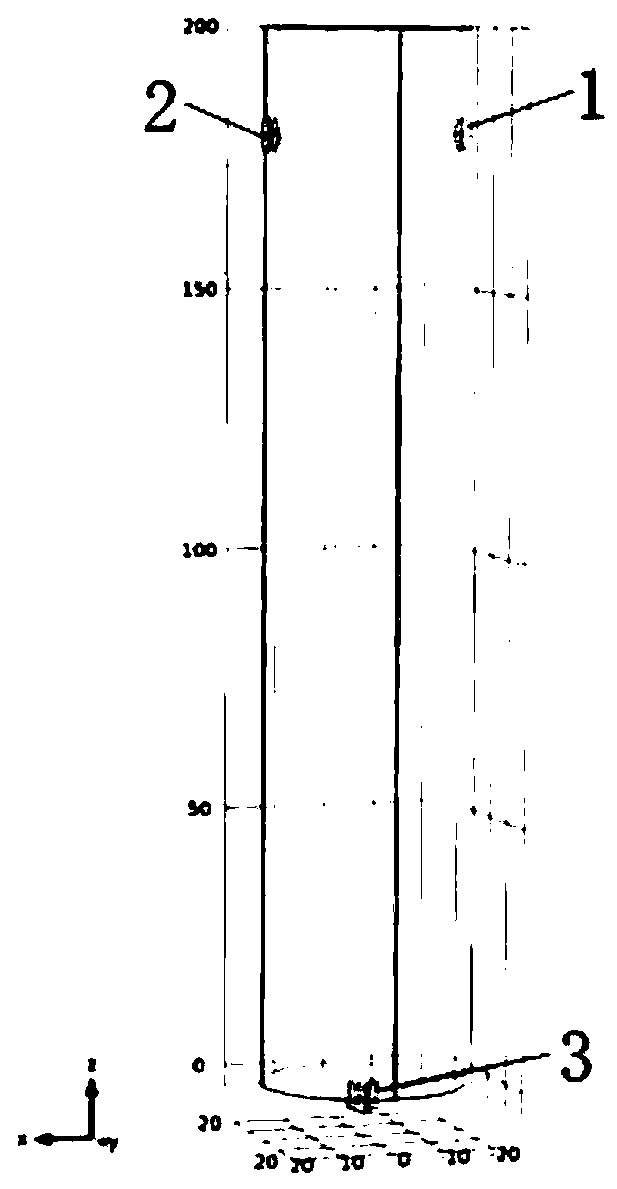

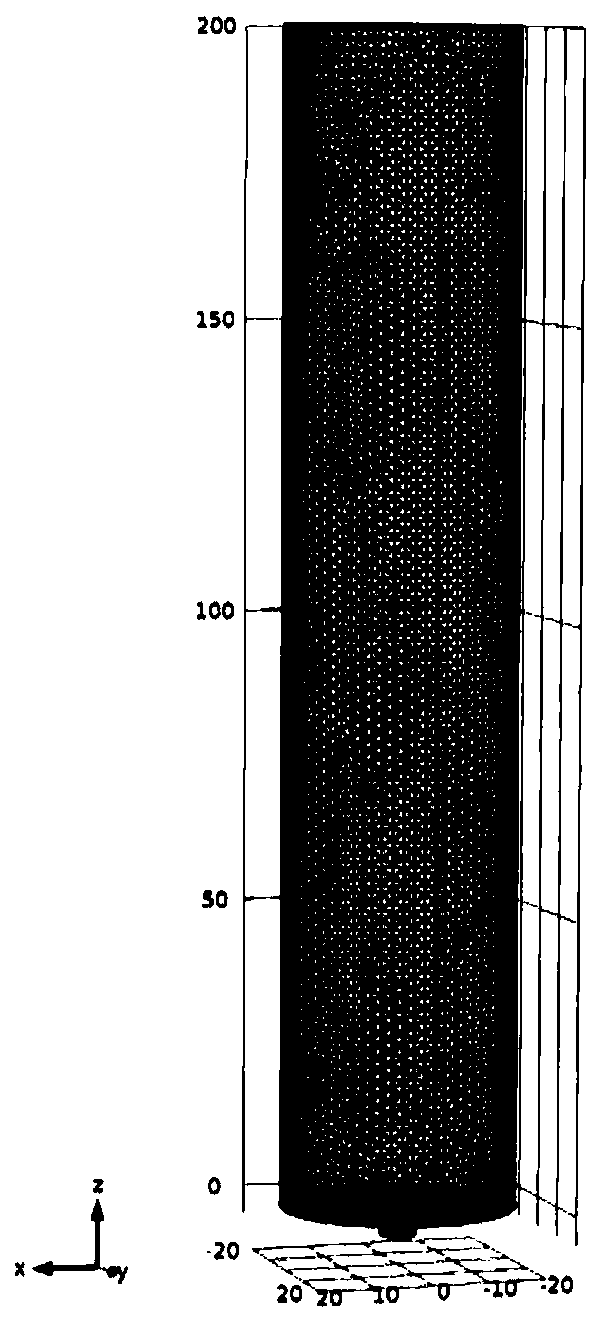

[0057] 1) Establish the geometric model of the reactor, and establish according to the design ideas such as Figure 1 In the geometric structure of the reactor shown, 1 in the figure is the inlet of heavy metal wastewater, 2 is the inlet of sodium sulfide solution, and 3 is the outlet of the reactor. The overall height of the reactor is 20cm, and the diameter is 4cm. The heavy metal waste water and the sodium sulfide solution enter the reactor through lateral convection at a height of 18 cm. 0m and z = 0.180m. The axis of the water outlet is in the z direction, and its coordinates are x=0m and y=0m, and the axis of the sodium sulfide solution inlet is in the x direction, and its coordinates are y=0m and z=0.180m.

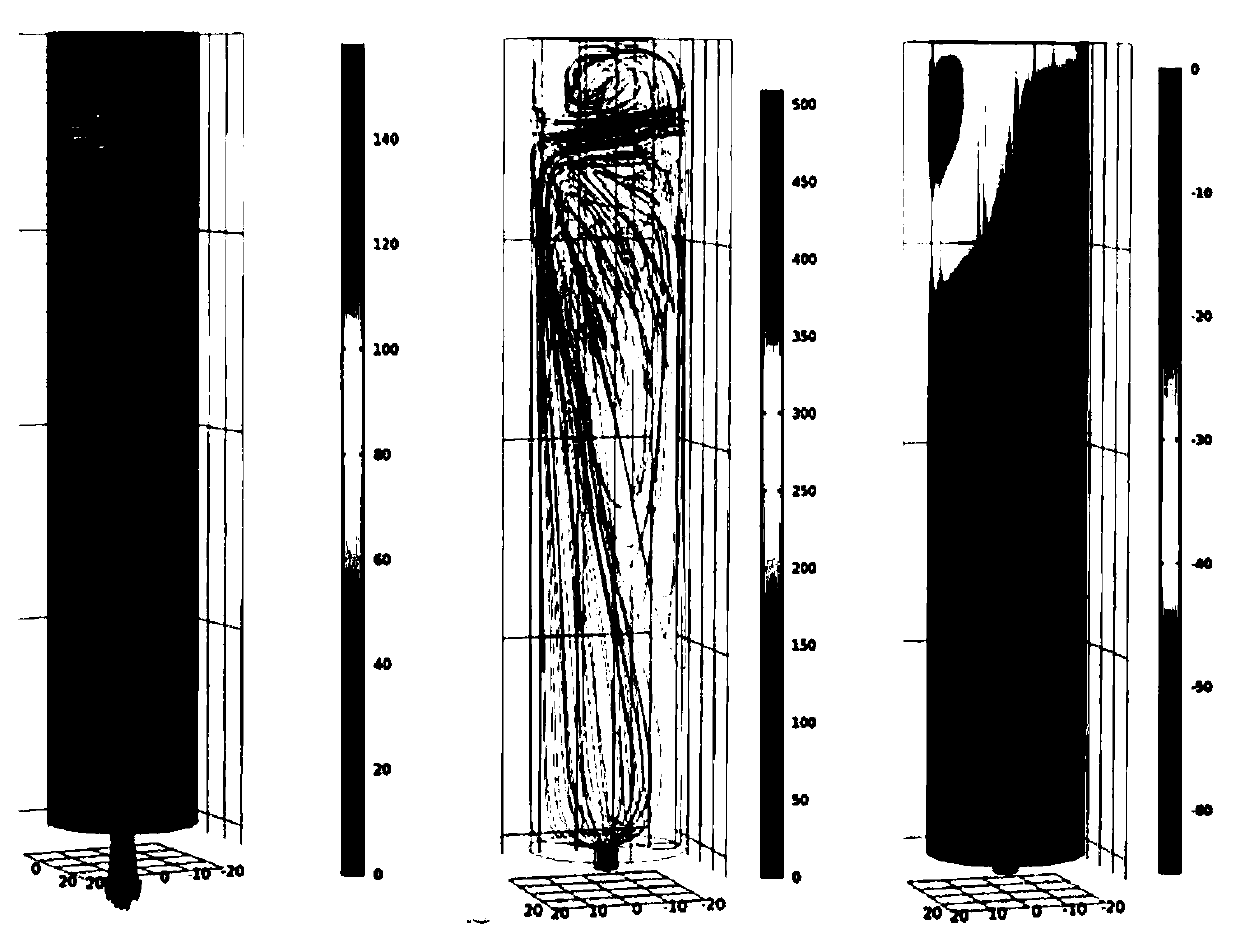

[0058] 2) Determine the control equation of the model, select the control equation according to the chemical transfer field and the flow field, in order to simulate the influence of the reactor structure on the mass transfer effect, the chemical reaction kinetics, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com