Glass-plastic hybrid lens

A lens and plastic lens technology, applied in optics, instruments, optical components, etc., can solve the problems of left volume, high cost, few high-quality lenses with super large aperture, etc., and achieve weight reduction and small field curvature and astigmatism, good resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

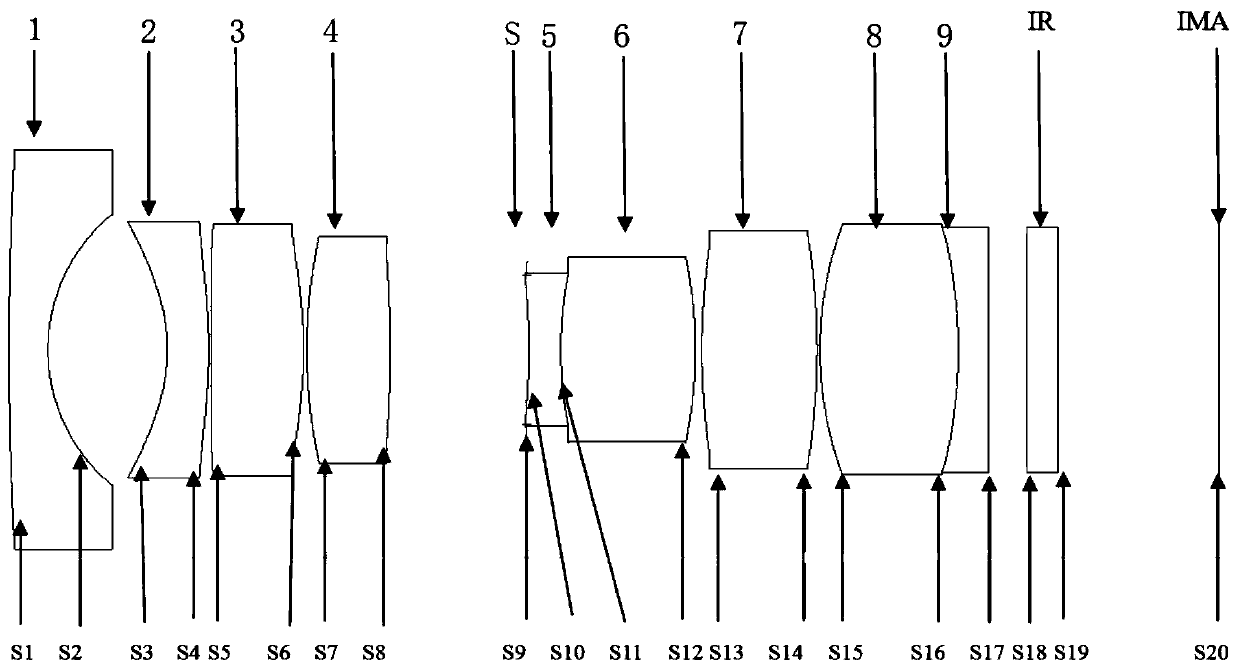

[0078] based on figure 1 The shown lens configuration is used to illustrate this embodiment.

[0079] The parameters of the camera lens in Embodiment 1 are as follows:

[0080] FNO=2.0; TTL / BFL=5.21; h / f=0.848; FOV=106°.

[0081] The following table 2 lists the relevant parameters of each lens of the present embodiment, including the refractive index of surface type, radius of curvature, thickness, material, Abbe number and conic coefficient:

[0082]

[0083] Table 2

[0084] In this embodiment, the aspherical data are shown in Table 3 below:

[0085]

[0086] table 3

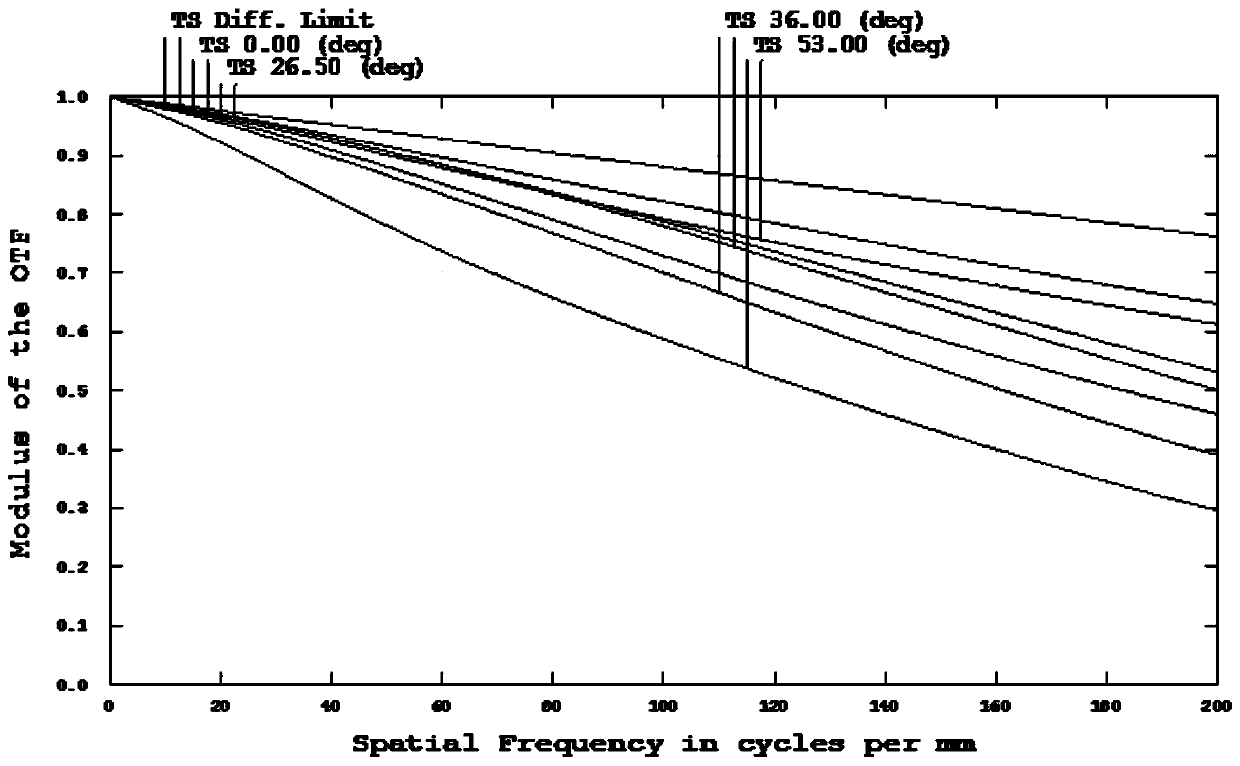

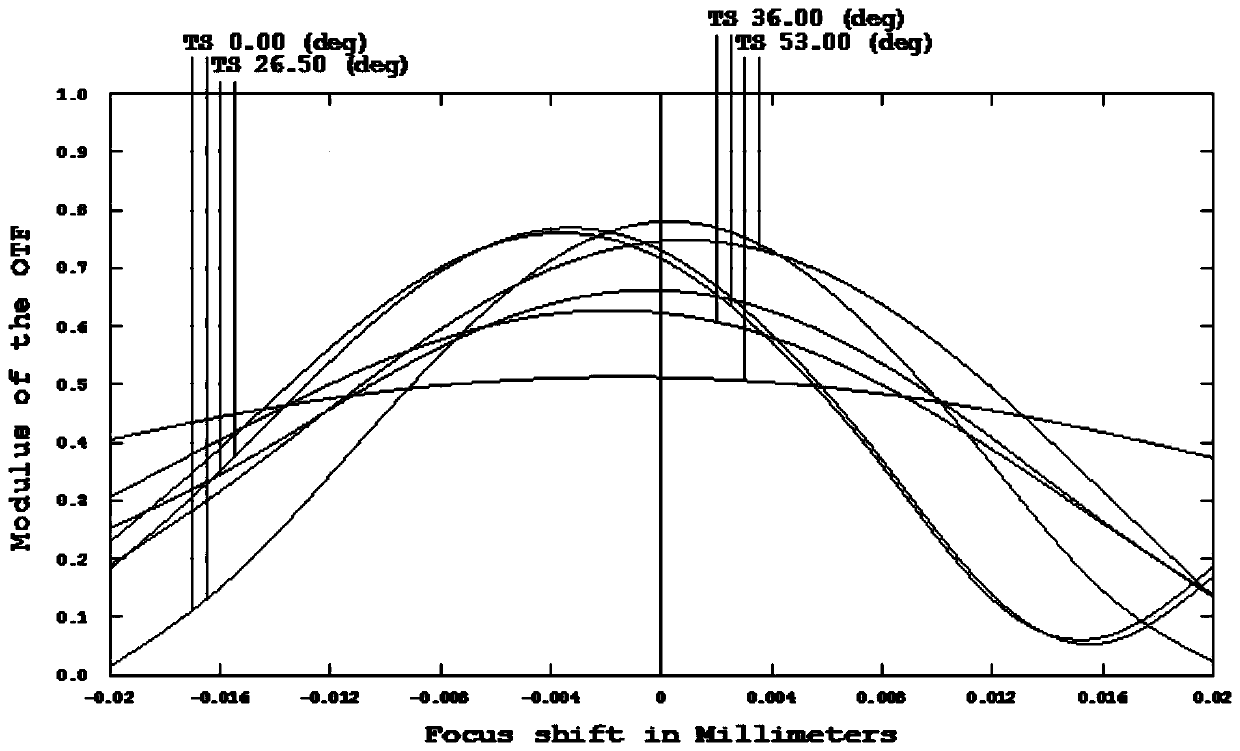

[0087] Figure 2 to Figure 5 Respectively schematically represent the MTF diagram of the glass-plastic hybrid lens of this embodiment under normal temperature 20°C and visible light; the Through Focus MTF diagram of 125 lp / mm under normal temperature 20°C under visible light; and the low temperature -40°C under visible light 125 lp / mm The Through Focus MTF diagram of 125lp / mm under visible light at...

Embodiment approach 2

[0091] Image 6 It schematically shows the structural diagram of the glass-plastic hybrid lens according to the second embodiment of the present invention. The description according to this embodiment is as follows:

[0092] The parameters of the camera lens in the second embodiment are as follows:

[0093] FNO=1.0; TTL / BFL=4.85; h / f=0.606; FOV=80°.

[0094] The following table 4 lists the relevant parameters of each lens of the present embodiment, including the refractive index of surface type, radius of curvature, thickness, material, Abbe number and conic coefficient:

[0095]

[0096]

[0097] Table 4

[0098] In this embodiment, the aspherical data are shown in Table 5 below:

[0099]

[0100] table 5

[0101] Figure 7 to Figure 10 Respectively schematically represent the MTF diagram of the glass-plastic hybrid lens of this embodiment under normal temperature 20°C and visible light; the Through Focus MTF diagram of 125 lp / mm under normal temperature 20°C und...

Embodiment approach 3

[0105] Figure 11 It schematically shows the structural diagram of the glass-plastic hybrid lens according to the third embodiment of the present invention. The description according to this embodiment is as follows:

[0106] The parameters of the camera lens in the third embodiment are as follows:

[0107] FNO=1.0; TTL / BFL=5.1; h / f=0.803; FOV=106°.

[0108] The following table 6 lists the relevant parameters of each lens of this embodiment, including the refractive index of surface type, curvature radius, thickness, material, Abbe number and conic coefficient:

[0109]

[0110] Table 6

[0111] In this embodiment, the aspherical data are shown in Table 7 below:

[0112]

[0113] Table 7

[0114] Figure 12 to Figure 15 Respectively schematically represent the MTF diagram of the glass-plastic hybrid lens of this embodiment under normal temperature 20°C and visible light; the Through Focus MTF diagram of 125 lp / mm under normal temperature 20°C under visible light; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com