One-way bearing type two-gear transmission of electric automobile

A technology for one-way bearings and electric vehicles, which is applied in the direction of transmission boxes, transmissions, gear transmissions, etc., to achieve the effect of fewer parts, helpful for promotion and popularization, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

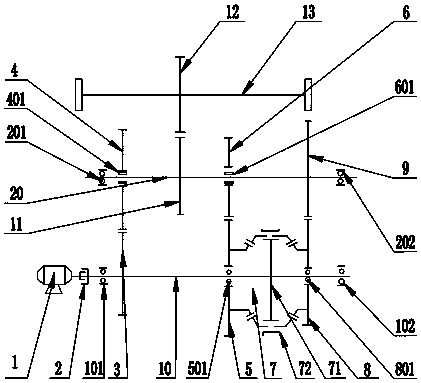

[0028] Such as Figure 1-4 As shown, the novel two-speed transmission for electric vehicles of the present invention includes a transmission housing system, a transmission gear transmission system, and a transmission shifting system. The transmission gear transmission system includes: a first shaft 10, a second shaft 20, and a first-speed driving gear 3. First gear driven gear 4, second gear driving gear 5, second gear driving gear needle roller bearing 501, second gear driven gear 6, reducer driving gear 11, reverse gear driving gear 8, reverse gear driving gear needle bearing 801, reverse gear driven gear 9, second reverse gear synchronizer assembly 7, one-way bearing 401 of first gear driven gear, one-way bearing 601 of second gear driven gear, front rolling bearing 101 and rear rolling bearing of first shaft 102 and its bearing seat and oil seal device, the rolling bearing 201 of the second shaft, the rear rolling bearing 202 and its bearing seat and oil seal device;

[002...

Embodiment 2

[0039] The new two-speed transmission for electric vehicles of the present invention can cancel the drive gear 11 of the reducer in the transmission, directly lengthen the second shaft 20, and extend out of the upper half part 14 of the transmission housing, and the second shaft 20 protrudes from the transmission housing. One end other than the upper half 14 is connected with the transmission shaft through a universal joint, and the transmission power is transmitted to the drive axle through the transmission second shaft 20 and the transmission shaft.

Embodiment 3

[0041] The shift control device in the transmission shift system includes: manual shift lever 76, shift cable or pull rod 75, manual shift lever 76 is connected with shift fork shaft 73 through pull cable or pull rod 75, when shifting At this time, the shift lever 76 is manipulated back and forth to form a pulling force and a pushing force on the shift fork shaft 73, so that the shift fork shaft 73 moves forward and backward, thereby realizing the shift control of the transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com