Soundproof and anti-corrosion floor in subway and high-speed railway carriages, and manufacturing method of soundproof and anti-corrosion floor

A production method and technology in the carriage, which are applied in railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of poor aesthetics and comfort, intensified vibration and noise, and cannot be effectively blocked. Inexpensive, noise-reducing, innovative and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

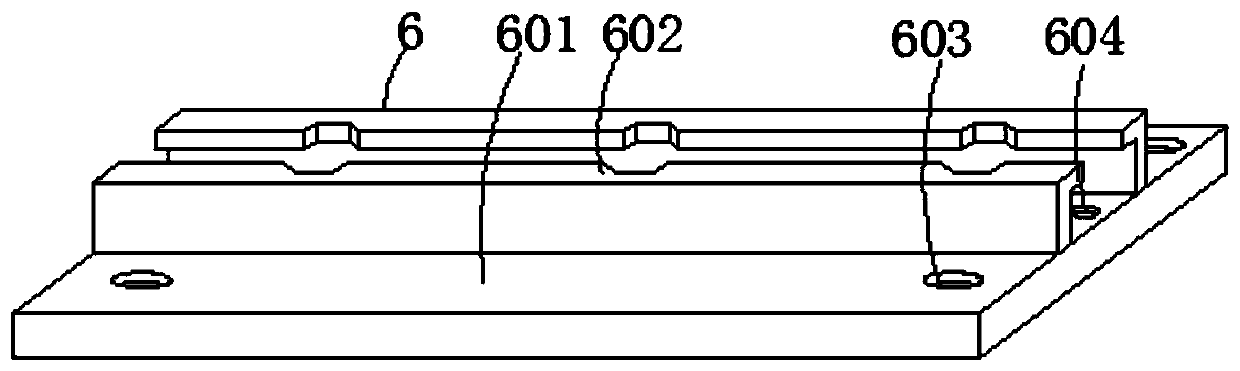

[0036] A sound-proof and anti-corrosion floor in a subway high-speed rail car, including a floor body 1, the floor body 1 includes an upper splint 101 and a lower splint 102, a sound insulation layer 2 is arranged between the upper splint 101 and the lower splint 102, and the outer side of the upper splint 101 is provided with The fire retardant paint layer 3, the middle position of the floor body 1 is provided with a first rectangular groove 4, the middle position of the first rectangular groove 4 is provided with a second rectangular groove 5, and the first rectangular groove 4 is movably installed with The seat fixing assembly 6, the seat fixing assembly 6 includes a seat fixing plate 601, the seat fixing plate 601 has the same size and shape as the first rectangular groove 4, and the lower end of the seat fixing plate 601 is provided with a mounting groove 602 along the midline position , the mounting holes 603 at the four corners of the seat fixing plate 601 , and the cent...

Embodiment 2

[0039] A sound-proof and anti-corrosion floor in a subway high-speed rail car, including a floor body 1, the floor body 1 includes an upper splint 101 and a lower splint 102, a sound insulation layer 2 is arranged between the upper splint 101 and the lower splint 102, and the outer side of the upper splint 101 is provided with The fire retardant paint layer 3, the middle position of the floor body 1 is provided with a first rectangular groove 4, the middle position of the first rectangular groove 4 is provided with a second rectangular groove 5, and the first rectangular groove 4 is movably installed with The seat fixing assembly 6, the seat fixing assembly 6 includes a seat fixing plate 601, the seat fixing plate 601 has the same size and shape as the first rectangular groove 4, and the lower end of the seat fixing plate 601 is provided with a mounting groove 602 along the midline position , the mounting holes 603 at the four corners of the seat fixing plate 601 , and the cent...

Embodiment 3

[0050] A sound-proof and anti-corrosion floor in a subway high-speed rail car, including a floor body 1, the floor body 1 includes an upper splint 101 and a lower splint 102, a sound insulation layer 2 is arranged between the upper splint 101 and the lower splint 102, and the outer side of the upper splint 101 is provided with The fire retardant paint layer 3, the middle position of the floor body 1 is provided with a first rectangular groove 4, the middle position of the first rectangular groove 4 is provided with a second rectangular groove 5, and the first rectangular groove 4 is movably installed with The seat fixing assembly 6, the seat fixing assembly 6 includes a seat fixing plate 601, the seat fixing plate 601 has the same size and shape as the first rectangular groove 4, and the lower end of the seat fixing plate 601 is provided with a mounting groove 602 along the midline position , the mounting holes 603 at the four corners of the seat fixing plate 601 , and the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com