A PID controller parameter control method for objects in thermal process

A technology of parameter control and controller, applied to controllers with specific characteristics, electric controllers, etc., can solve problems such as difficulty in obtaining control effects, slow convergence speed, complicated programming language, etc., and achieve small overshoot and fast Controlled speed, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further introduced below in conjunction with specific embodiments.

[0029] This specific embodiment discloses a PID controller parameter control method for an object in a thermal process, comprising the following steps:

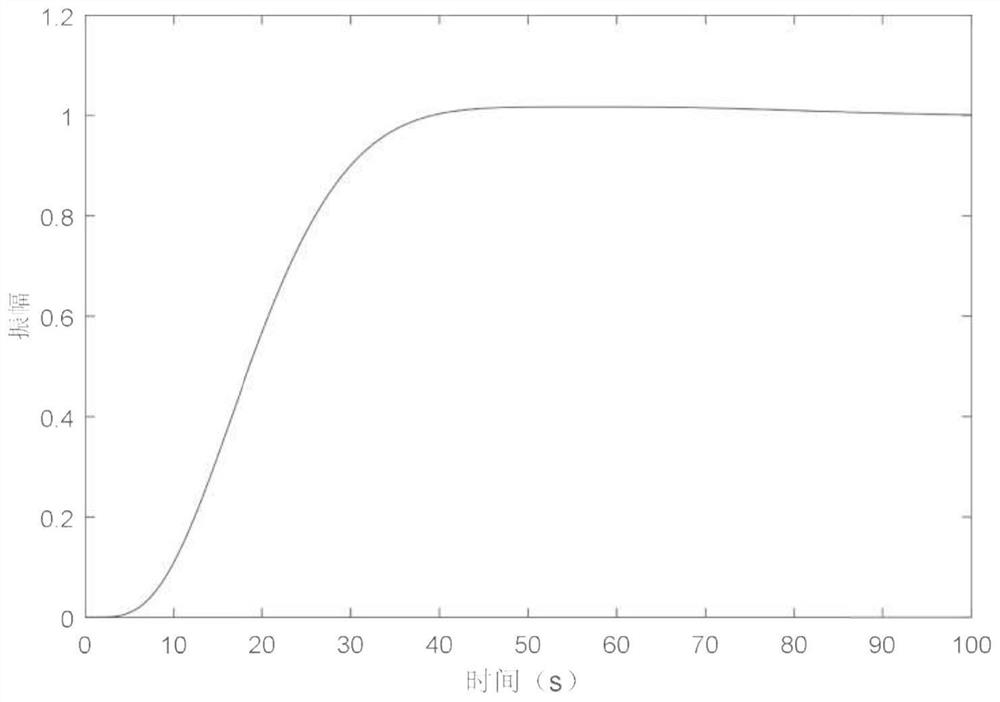

[0030] S1: Establish a higher-order transfer function model of the object;

[0031] S2: Use the asymptote of the Nyquist curve of the open-loop transfer function to establish an equation to determine k in the PID controller parameters p , the integration time constant T i the relationship with the higher-order transfer function model parameters of the object;

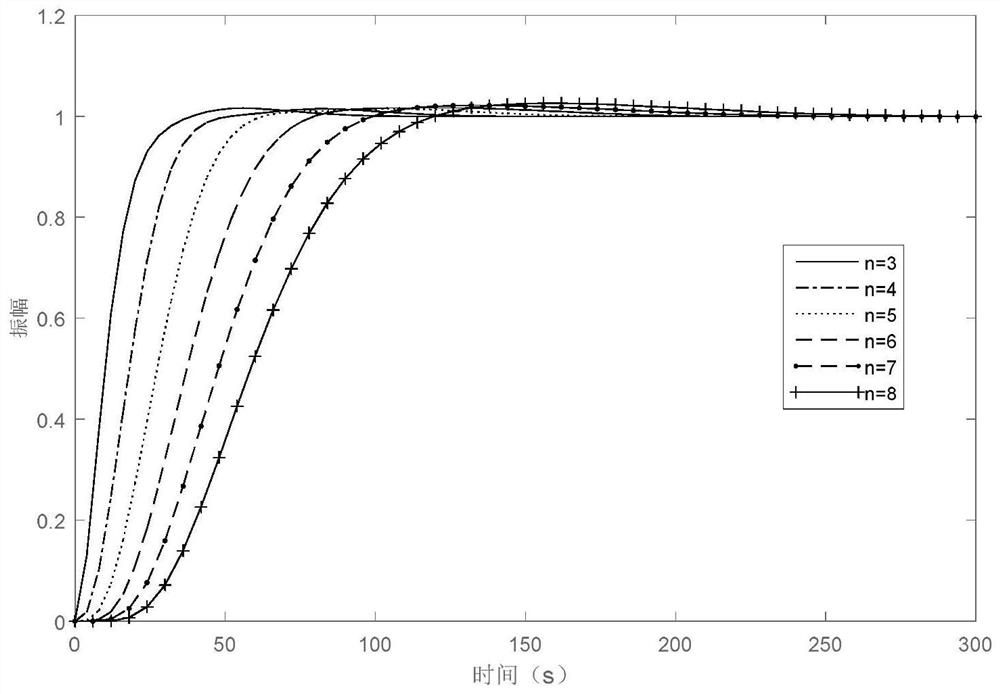

[0032] S3: Determine the integral time constant T i The relationship between the order n of the higher-order transfer function model and the time constant T of the higher-order transfer function model;

[0033] S4: Determine the differential time constant T in the PID controller d with the integration time constant T i The relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com