A kind of physical similarity simulation experiment material and preparation method thereof

A technology for physically similar simulation and experimental materials, applied in the field of physically similar simulation experimental materials and their preparation, can solve problems such as difficult to simulate weak rock formations, difficult natural collapse of overlying rock formations, and high strength of similar materials, achieving short maintenance time, The effect of low cost and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of the test piece is as follows:

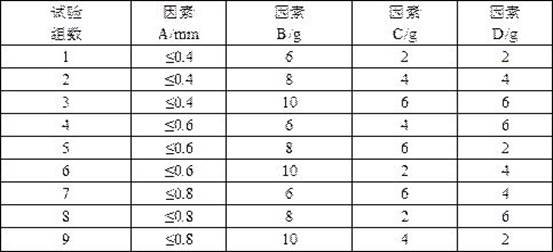

[0025] Step 1. Use different types of stainless steel sieves to sieve river sand according to the required particle size; in this embodiment, use stainless steel sieves to sieve river sand with a particle size of ≤0.4 mm and uniform gradation.

[0026] Step 2. Using an electronic scale, weigh river sand, cement, water glass and starch according to the weight ratio; in the present embodiment, weigh: 100 parts of river sand with a particle size≤0.4mm, 6 parts of cement, and water glass 2 parts, 2 parts starch. That is, take 100g of river sand with a particle size of ≤0.4mm, 6g of cement, 2g of water glass, and 2g of starch.

[0027] Step 3, placing the river sand, cement and starch weighed in step 2 in a container or a blender to mix and stir evenly;

[0028] Step 4. Add water glass and an appropriate amount of water to the uniformly stirred material in step 3 according to the proportion by weight, and then full...

Embodiment 2

[0033] The preparation process of the test piece is as follows:

[0034] Step 1. Use different types of stainless steel sieves to sieve river sand according to the required particle size; in this embodiment, use stainless steel sieves to sieve river sand with a particle size of ≤0.4 mm and uniform gradation.

[0035] Step 2. Using an electronic scale, weigh the river sand, cement, water glass and starch respectively according to the weight ratio; in this embodiment, weigh: 100 parts of river sand with a particle size≤0.4mm, 8 parts of cement, and water glass 4 parts, 4 parts starch. That is, take 100g of river sand with a particle size of ≤0.4mm, 8g of cement, 4g of water glass, and 4g of starch.

[0036] Step 3, placing the river sand, cement and starch weighed in step 2 in a container or a blender to mix and stir evenly;

[0037] Step 4. Add water glass and an appropriate amount of water to the uniformly stirred material in step 3 according to the proportion by weight, and...

Embodiment 3

[0042] The preparation process of the test piece is as follows:

[0043] Step 1. Use different types of stainless steel sieves to sieve river sand according to the required particle size; in this embodiment, use stainless steel sieves to sieve river sand with a particle size of ≤0.4 mm and uniform gradation.

[0044] Step 2. Use an electronic scale to weigh river sand, cement, water glass and starch according to the weight ratio; in this embodiment, weigh: 100 parts of river sand with a particle size≤0.4mm, 10 parts of cement, and water glass 6 parts, 6 parts of starch. That is, take 100g of river sand with a particle size of ≤0.4mm, 10g of cement, 6g of water glass, and 6g of starch.

[0045] Step 3, placing the river sand, cement and starch weighed in step 2 in a container or a blender to mix and stir evenly;

[0046] Step 4. Add water glass and an appropriate amount of water to the uniformly stirred material in step 3 according to the proportion by weight, and then fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com