Fabricated wall surface keel structure capable of being leveled

A prefabricated and keel technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of time-consuming and labor-consuming, keel damage, etc., and achieve the effects of improving installation efficiency, convenient replacement, and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

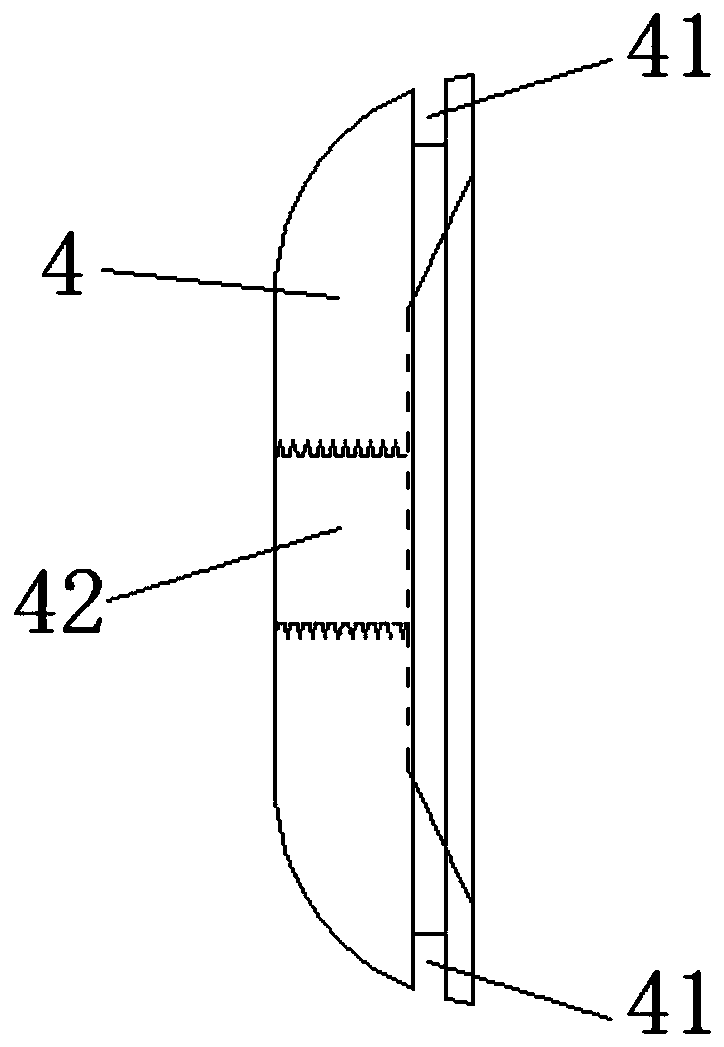

[0036] see Figure 1 to Figure 5 , the figure shows a levelable assembled wall keel structure provided by Embodiment 1 of the present invention, including: a wall panel 1, a leveling base 2, which is fixedly connected to the wall 3; a leveling piece 4 , its thread adjustment is connected to the leveling base 2, the outer surface of the leveling member 4 is an arc surface, and the whole is disc-shaped, and along its radial direction, the outer circumference of the leveling member 4 is provided with a card slot 41; the keel 5, its The upper and lower ends along the width direction are provided with hooks 51 , and the hooks 51 are engaged with the slots 41 ; the pendant 6 is fixedly arranged on the wallboard 1 , and the pendant 6 is hooked on the leveling member 4 and the keel 5 .

[0037] A levelable assembled wall keel structure provided in this embodiment mainly includes a wallboard 1, a leveling base 2, a leveling piece 4, a keel 5 and a pendant 6, and the pendant 6 is fixedl...

Embodiment 2

[0045] see figure 1 , figure 2 and image 3 , the figure shows a levelable assembled wall keel structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The leveling base 2 includes a base plate 21 and an adjusting screw 22 arranged on the base plate 21. The base plate 21 is fixedly connected to the wall body 3 through an expansion bolt 23. Specifically, the base plate 21 is square; the middle of the leveling member 4 is provided with an adjusting screw hole 42, the adjusting screw hole 42 is a through hole; the adjusting screw rod 22 is threadedly connected to the adjusting screw hole 42; a connecting plate 24 is arranged between the bottom plate 21 and the adjusting screw rod 22; connecting frames 25 are arranged on both sides of the connecting plate 24. Through the setting of the above structure, the leveling base 2 is fixedly connected to t...

Embodiment 3

[0047] see figure 1 , Figure 4 and Figure 5 , the figure shows a levelable assembled wall keel structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The cross section of the keel 5 is in the shape of “[”; specifically, the keel 5 is a C-shaped channel steel; the hanger 6 is in an inverted “J” shape; the hanger 6 is fixedly connected to the wallboard 1 by screws 61 . Through the setting of the above structure, it is convenient to clamp the keel 5 and the pendant 6, which saves installation time and makes the installation more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com