A kind of composite autotrophic nitrifying bacteria, preparation method of its solid bacterial agent and its application in the sewage treatment containing high salinity and high ammonia nitrogen

A nitrifying bacteria, mixed technology, applied in biological water/sewage treatment, biochemical equipment and methods, water/sludge/sewage treatment, etc., can solve the problem of reducing sewage treatment efficiency, increasing sewage treatment cost, and low tolerance and other problems, to achieve the effect of high tolerance, fast startup and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 compound autotrophic nitrifying bacteria

[0026] (1) Activation of Bacillus and Pseudomonas

[0027] The Bacillus and Pseudomonas preserved on the slant were respectively inoculated on the solid medium, and cultured in a constant temperature incubator at 30°C for 12 days to obtain activated Bacillus and Pseudomonas respectively. The Bacillus used was specific Bacillus subtilis ATCC 6633, Pseudomonas specifically Pseudomonas aeruginosa BNCC185967.

[0028] (2) Preparation of the bacterial suspension of compound autotrophic nitrifying bacteria

[0029] The expansion culture medium is divided into 250mL Erlenmeyer flasks, and the filling volume is 150mL / bottle, and the activated bacillus and pseudomonas are respectively inoculated into two rings from the solid medium to the expansion medium. In the Erlenmeyer flask, the enrichment culture was carried out on a constant temperature shaker at 30°C at 150r / min, and the culture time was 5 days...

Embodiment 2

[0035] Example 2 Composite autotrophic nitrifying bacteria and common nitrifying bacteria agent in the comparison of ammonia nitrogen degradation in artificial simulated sewage

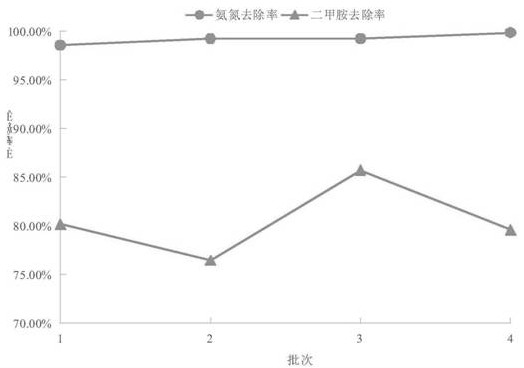

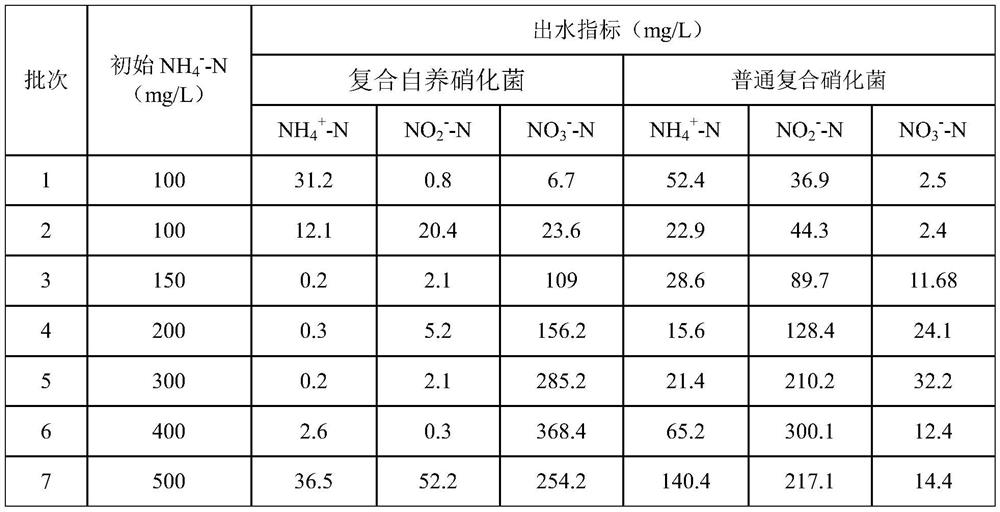

[0036] The composite autotrophic nitrifying bacteria prepared in Example 1 and the common nitrifying bacteria agent were dropped into two identical MBBR devices respectively, and the dosage was 1‰ (m / V), and the filler in the MBBR device was a modified polyurethane filler , the dosage is 15% (V / V), artificial simulated sewage is prepared according to Table 1, the 1-4 batches are the system start-up stage, the residence time is 72h, the 5-7 batches are the ammonia nitrogen degradation stage after startup, each batch is Water 700mL, residence time 48h; control the dissolved oxygen in the two MBBR devices of each batch to 6mg / L, the temperature is 30 ℃; 4 + -N, NO 2 - -N, NO 3 - -N, the results are shown in Table 2

[0037] Table 1 Composition of artificial simulated sewage

[0038] batc...

Embodiment 3

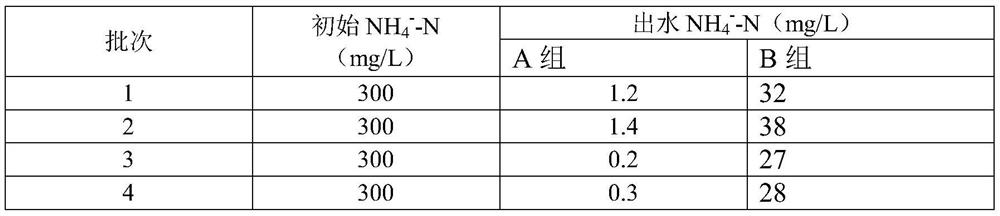

[0043] Example 3 Comparison of the degradation of ammonia nitrogen in artificial simulated sewage by compound autotrophic nitrifying bacteria with different ratios

[0044] Group A: Mix the bacterial suspensions of Bacillus and Pseudomonas at a ratio of 1:2.5 (V / V) to obtain a high-salt compound autotrophic nitrifying bacteria suspension.

[0045] Group B: Mix the bacterial suspensions of Bacillus and Pseudomonas at a ratio of 1:1 (V / V) to obtain a high-salt compound autotrophic nitrifying bacteria suspension.

[0046] The preparation method of the solid microbial agent of group A and group B is basically the same as the preparation method of embodiment 1, the difference is only that the mixing ratio of bacillus and pseudomonas is different; the 2 batches of system startup are not listed in table 3 It is shown that the initial NH4--N in the start-up phase is 300mg / L.

[0047] Table 3 Degradation of ammonia nitrogen by compound autotrophic nitrifying bacteria with different pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com