Pit-type drip irrigation device

A technology of pit and irrigator is applied in the field of agricultural irrigation, which can solve the problems of increased dissipation and high flow index, and achieve the effects of reducing flow index, long service life and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

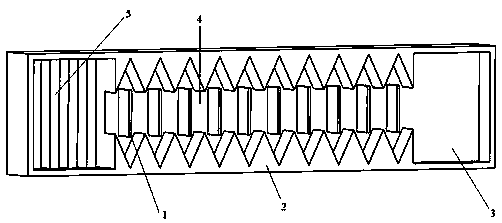

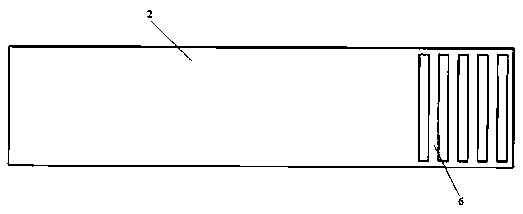

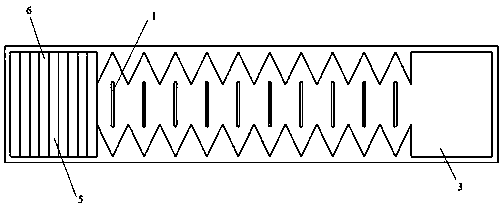

[0025] like Figures 1 to 7 As shown, the pit type drip irrigation device includes a pit type drip irrigation emitter 2 and a pipeline device;

[0026] The pit type drip irrigation emitter 2 includes a water outlet 3, a pit flow channel 4, a water inlet 5 and a filter plate 6, and the pit flow channel 4 includes a plurality of symmetrical pit flow channel unit structures, each pit flow channel The unit structure includes a vertically symmetrical toothed structure and a water baffle 1; the pipeline device includes a pipeline 7 and a drop opening 8;

[0027] Several pit-type drip irrigation emitters 2 are evenly arranged in the inner wall of the pipeline 7, each pit-type drip irrigation emitter 2 is a cuboid structure, and each pit-type drip irrigation emitter 2 is located on the top side of the pipeline 7. There is a filter plate 6, the bottom of the filter plate 6 is provided with a through water inlet 5 to the bottom surface of the pit type drip irrigation emitter 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com