Main shaft mechanism for winding machine with multi-angle rotation

A technology of rotating spindles and winding machines, which is applied in coil manufacturing, electromechanical devices, and motor generator manufacturing, etc. It can solve problems such as high precision requirements and complex production processes, meet the needs of synchronous rotation, improve winding efficiency and automation Degree, control precise and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

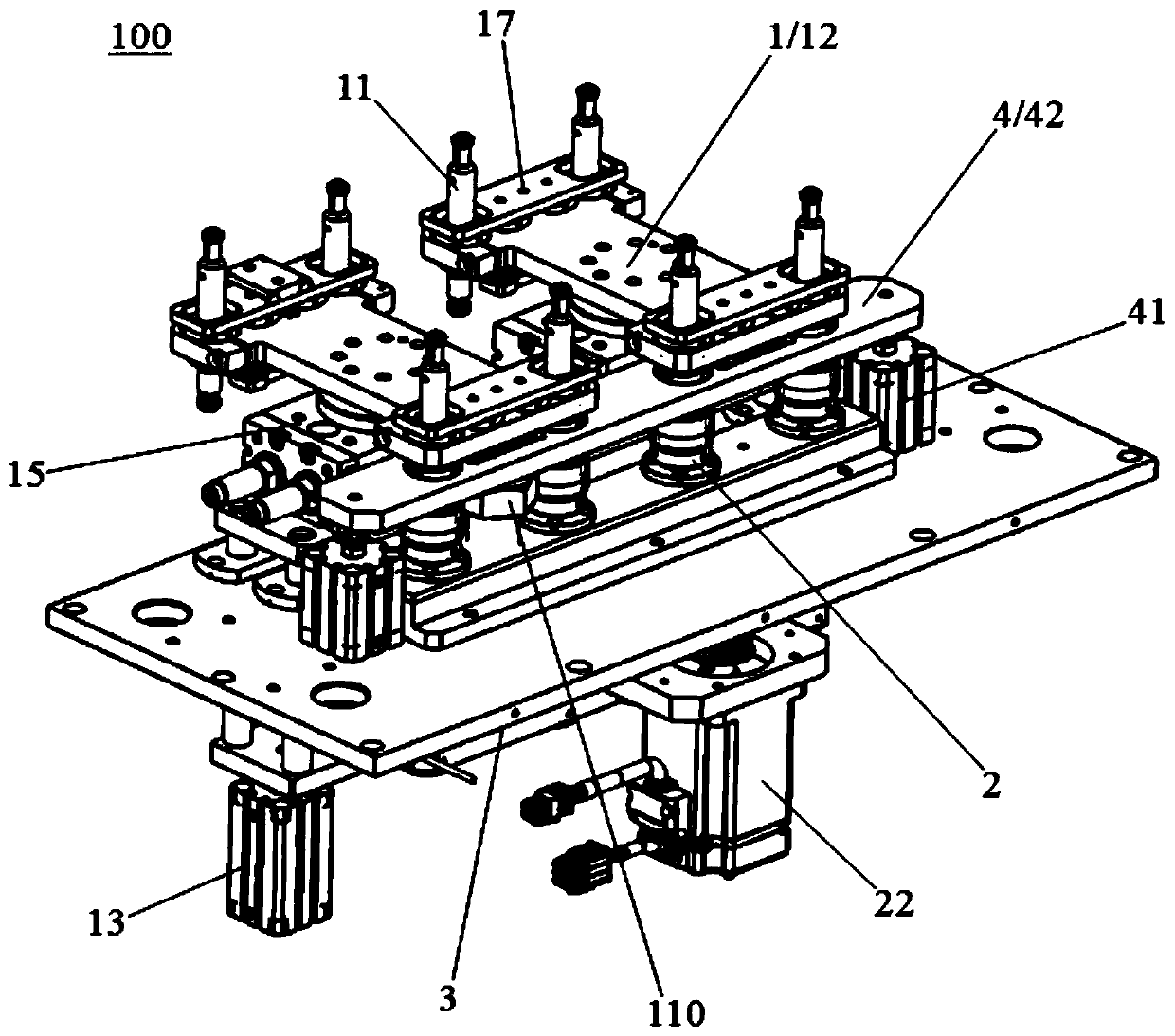

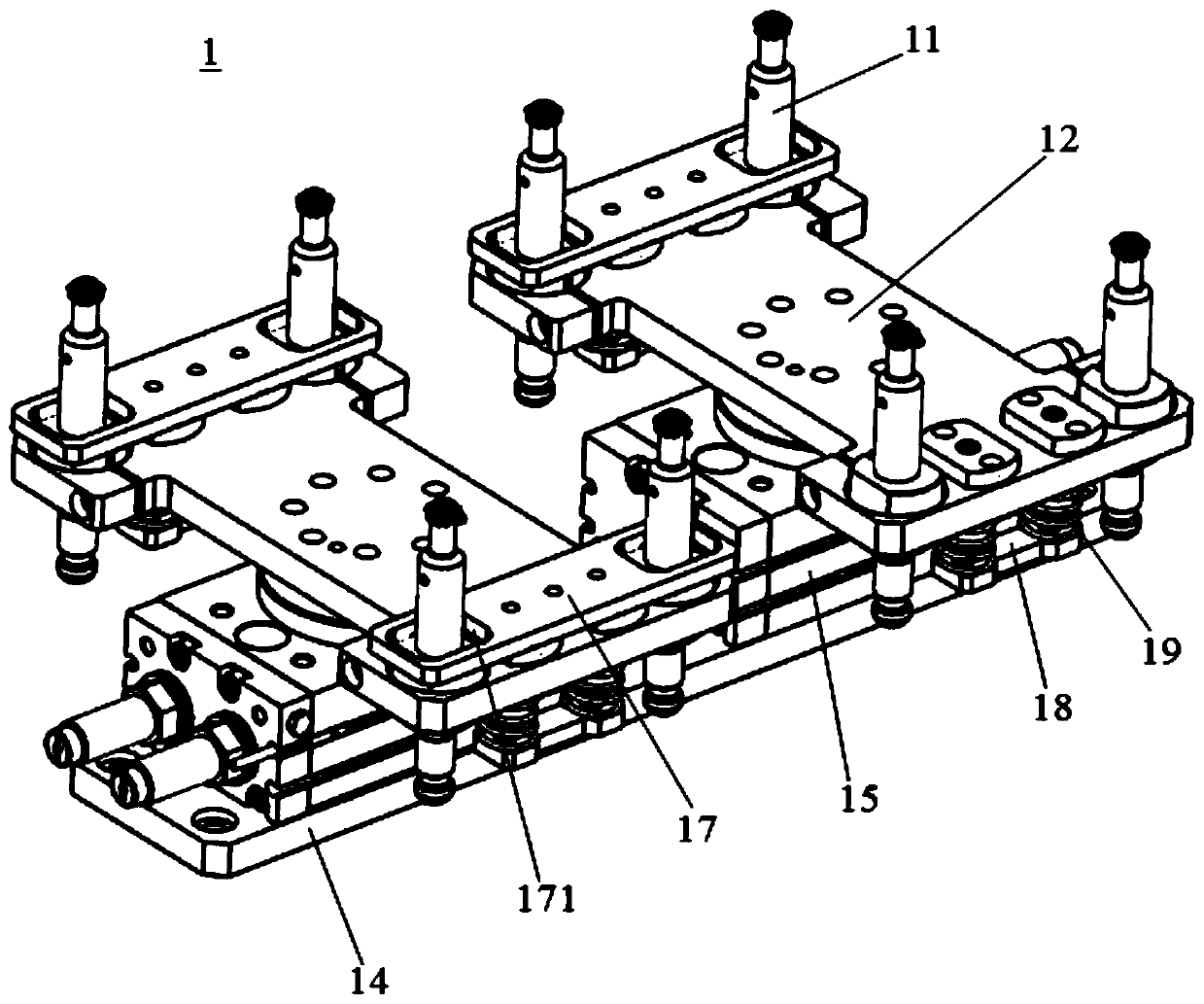

[0034] Please refer to Figure 1-Figure 6 , the present embodiment is a winding machine spindle mechanism 100 with multi-angle rotation, which includes a rotary feeding jig 1, a spindle drive unit 2 that drives the jig shaft 11 in the rotary feeding jig 1 to rotate, and prevents The anti-rotation unit 3 of the rotation main shaft 21 in the main shaft drive unit 2 , the unlocking unit 4 of the unlocking jig shaft 11 and the rotation main shaft 12 with a clamping structure so that the two can be separated.

[0035] The rotary feeding jig 1 includes a first cylinder 13, a first support plate 14 driven by the first cylinder 13 to move up and down, at least one rotary cylinder 15 fixed on the first support plate 14, driven by the rotary cylinder 15 to move The rotating rotating plate 12 and the jig shafts 11 placed on the rotating plate 12 and located on both sides.

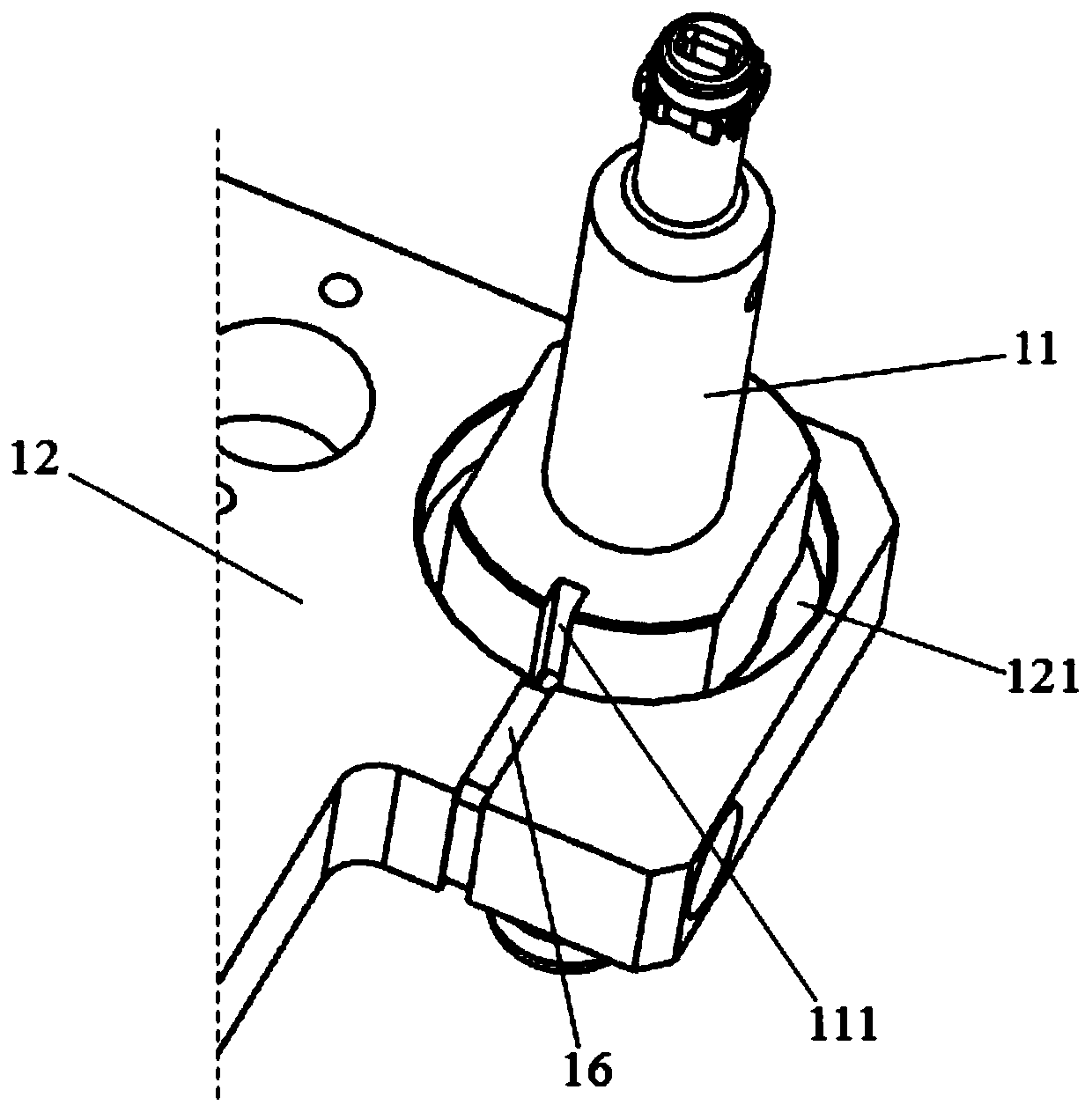

[0036] The rotating plate 12 is provided with a sinking hole 121, and the jig shaft 11 passes through the sinking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com