Factory process management system and method

A management method and management system technology, applied in the field of factory process management system, can solve the problems of limited information, troublesome paper record filing, inconvenient information query and traceability, etc., to achieve clear process management, convenient traceability, and prevention of process skipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

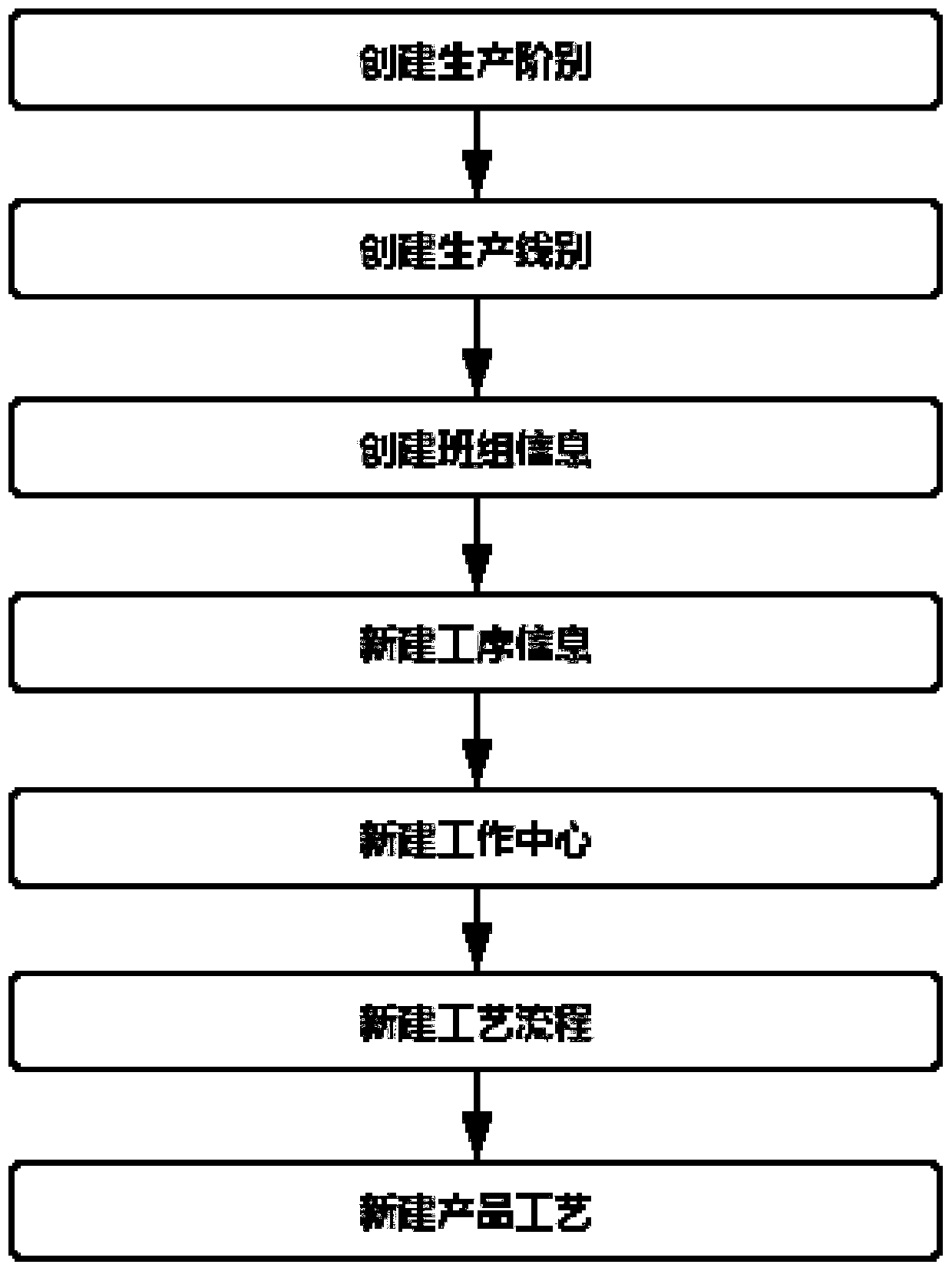

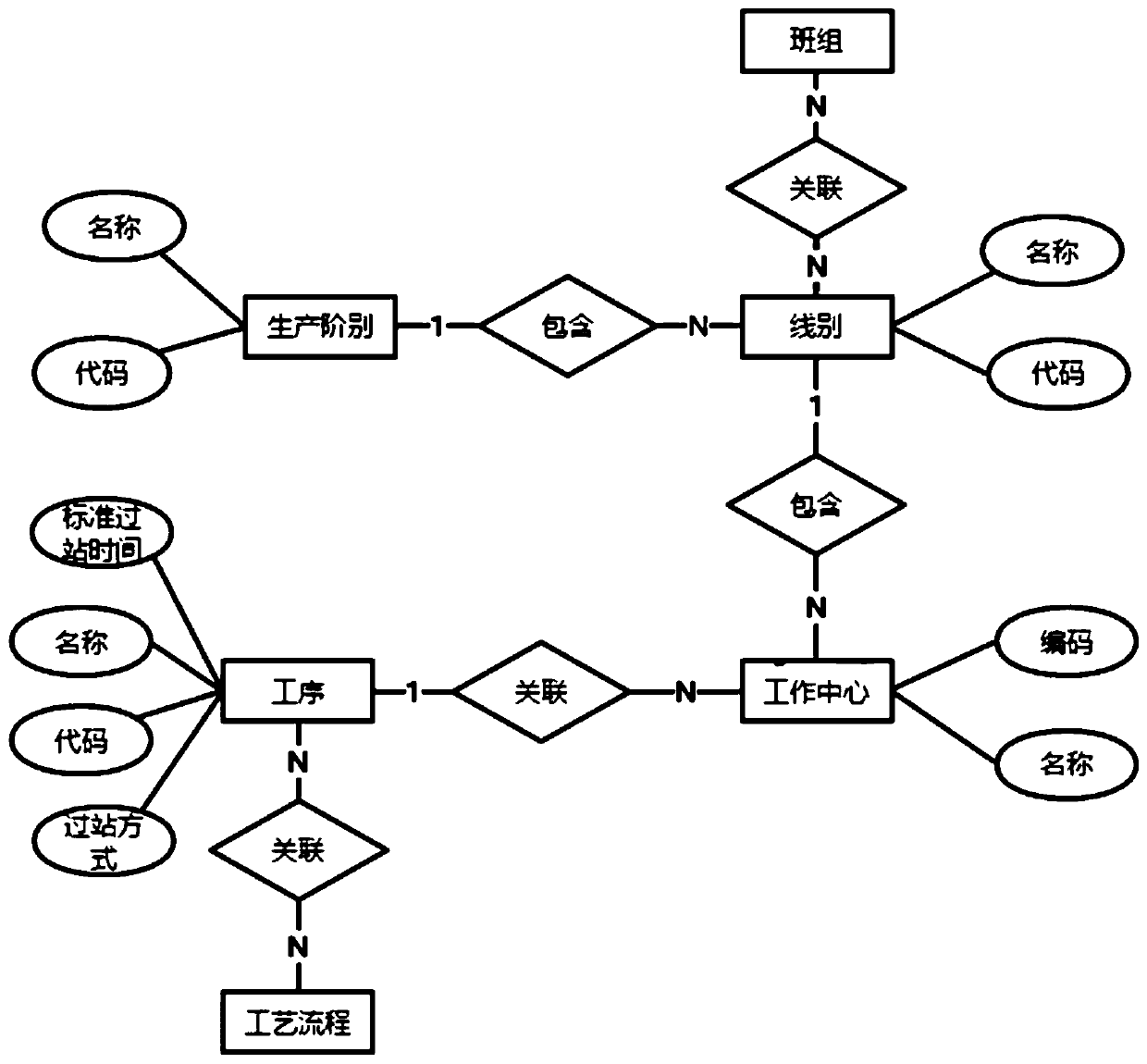

[0030] A factory process management system includes a material management module, a production stage management module, a production line management module, a team management module, a process management module, a work center management module and a process management module.

[0031] The material management module is used to manage the factory material information, and different materials have different material codes; the production level management module is used to maintain the factory production level information, and the production line management module is used to maintain the factory production level information. The production level corresponds to multiple production lines, that is, the production line needs to be created on the basis of the production level, and there can be multiple production lines under one production level; the team management module is used for the management of team personnel information, and the process management module is used for Maintain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com