Joint base

A joint seat, male plug technology, applied in the direction of connection, contact parts, base/shell, etc., can solve the problems of accidental separation of male plug and female plug, unable to eliminate cable twisting, inconvenient operation and construction, etc., to increase the operating experience, Easy to operate and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

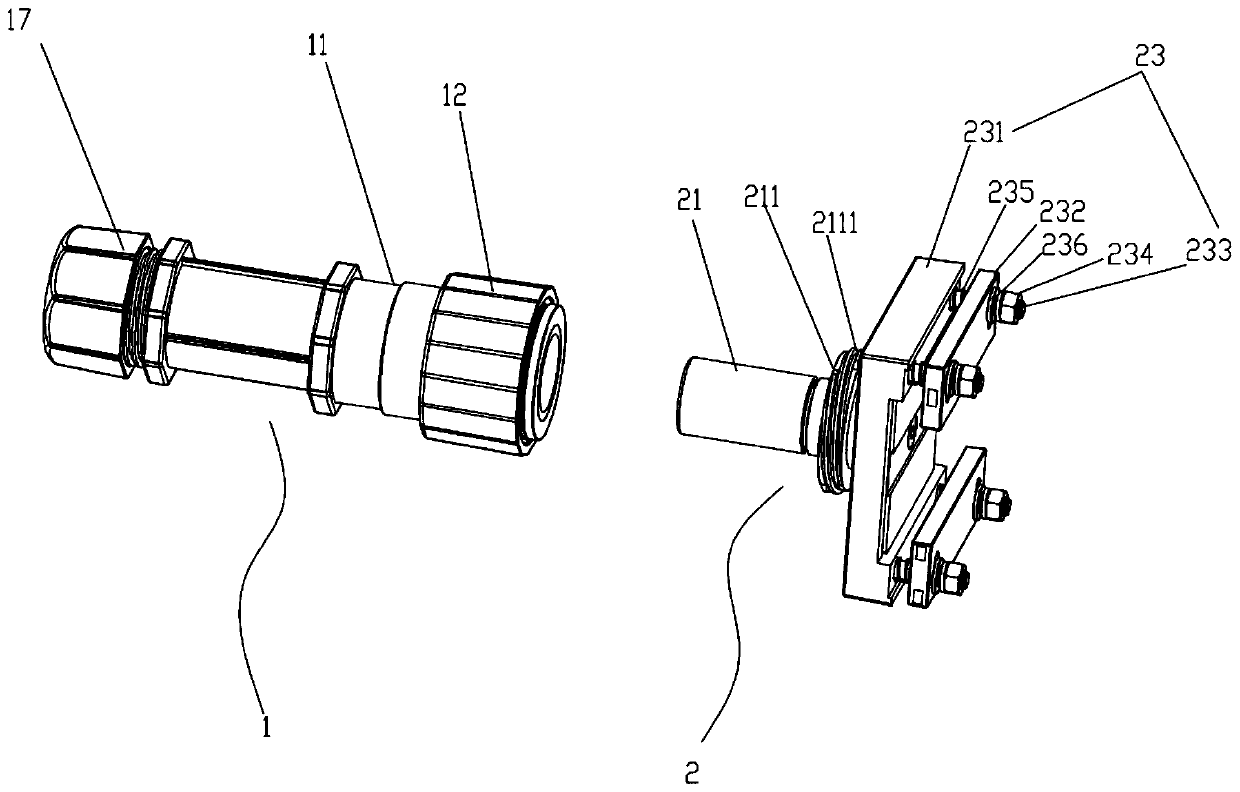

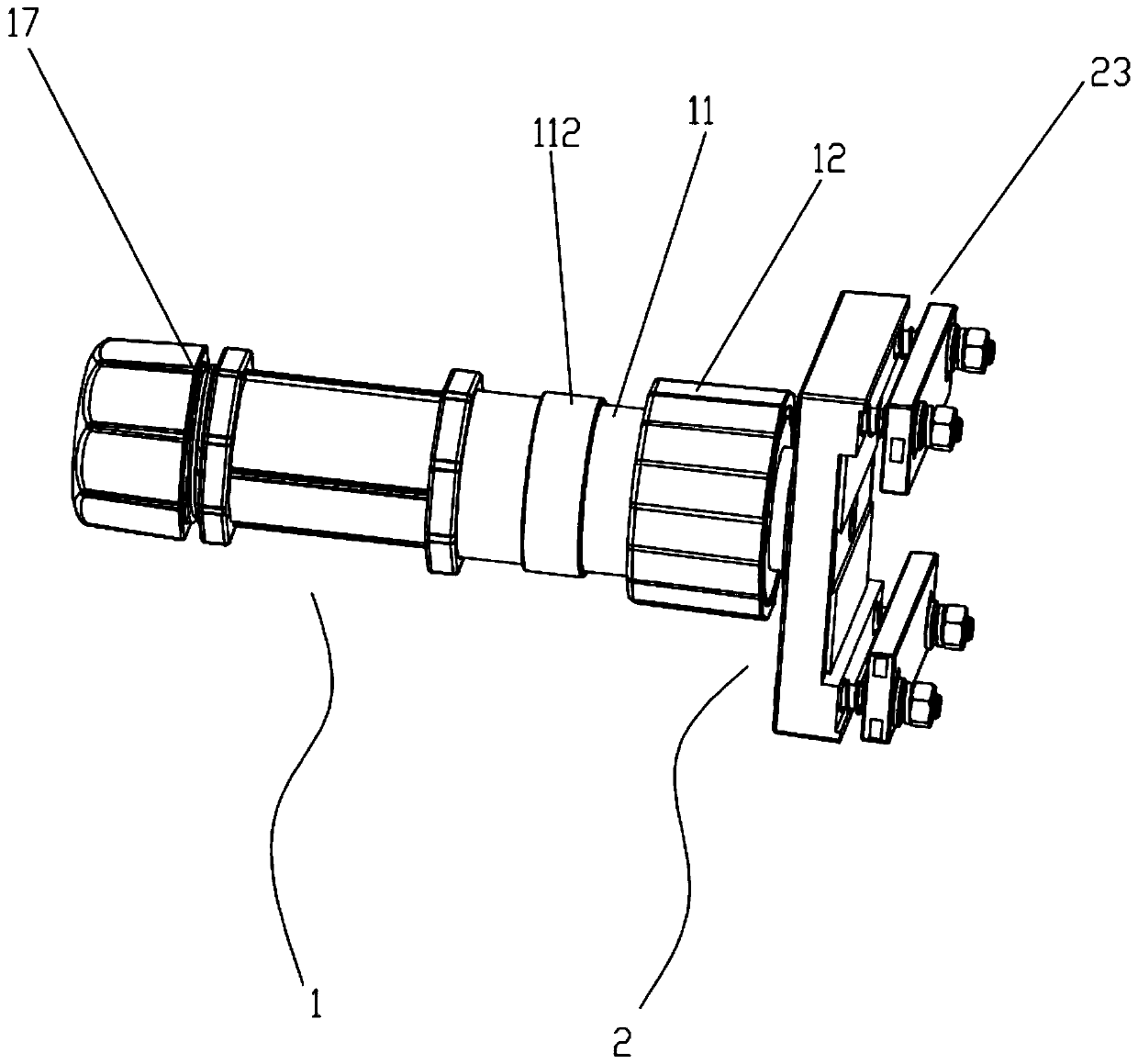

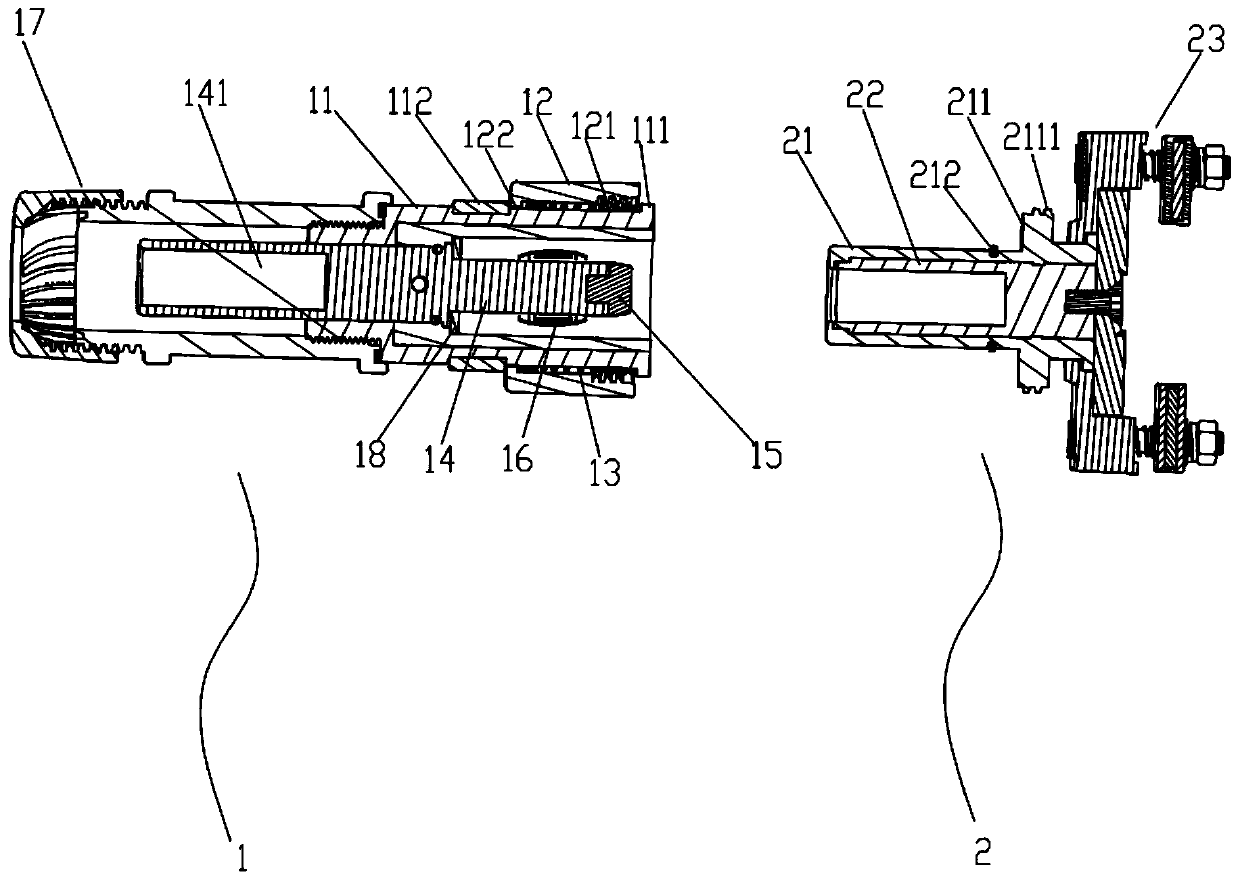

[0026] like Figure 1-5As shown, a joint seat includes a male plug 2 and a female plug 1, the male plug 2 includes a socket 21, the rear end of the socket 21 is provided with a connecting plate 211, and the outer wall of the connecting plate 211 is provided with an outer Thread 2111, the inner wall of the socket 21 is provided with a conductive cylinder 22; the female plug 1 includes an insulating sleeve 11, a conductive finger 14, a lock cylinder 12 and a return spring 13, and the conductive finger 14 is coaxially fixed on the insulating In the inner cavity of the sleeve 11, the lock cylinder 12 is movably sleeved outside the insulating sleeve 11, so that the lock cylinder 12 can not only rotate relative to the insulation sleeve 11, but also slide axially relative to the insulation sleeve 11. The front end of the lock cylinder 12 The inner side wall of the inner side wall is provided with the internal thread 121 matching the external thread 2111 of the connecting plate 211, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com