Hot-press type tunnel ventilating system for high altitude and high ground temperature long tunnel

A technology for tunnel ventilation and high ground temperature, which is applied in the ventilation of mines/tunnels, tunnels, mining equipment, etc. It can solve the problems that the ventilation volume cannot meet the cooling requirements, it is difficult to avoid personnel damage, and cannot be used, and the natural ventilation volume can be improved and avoided. Damage, the effect of raising the air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

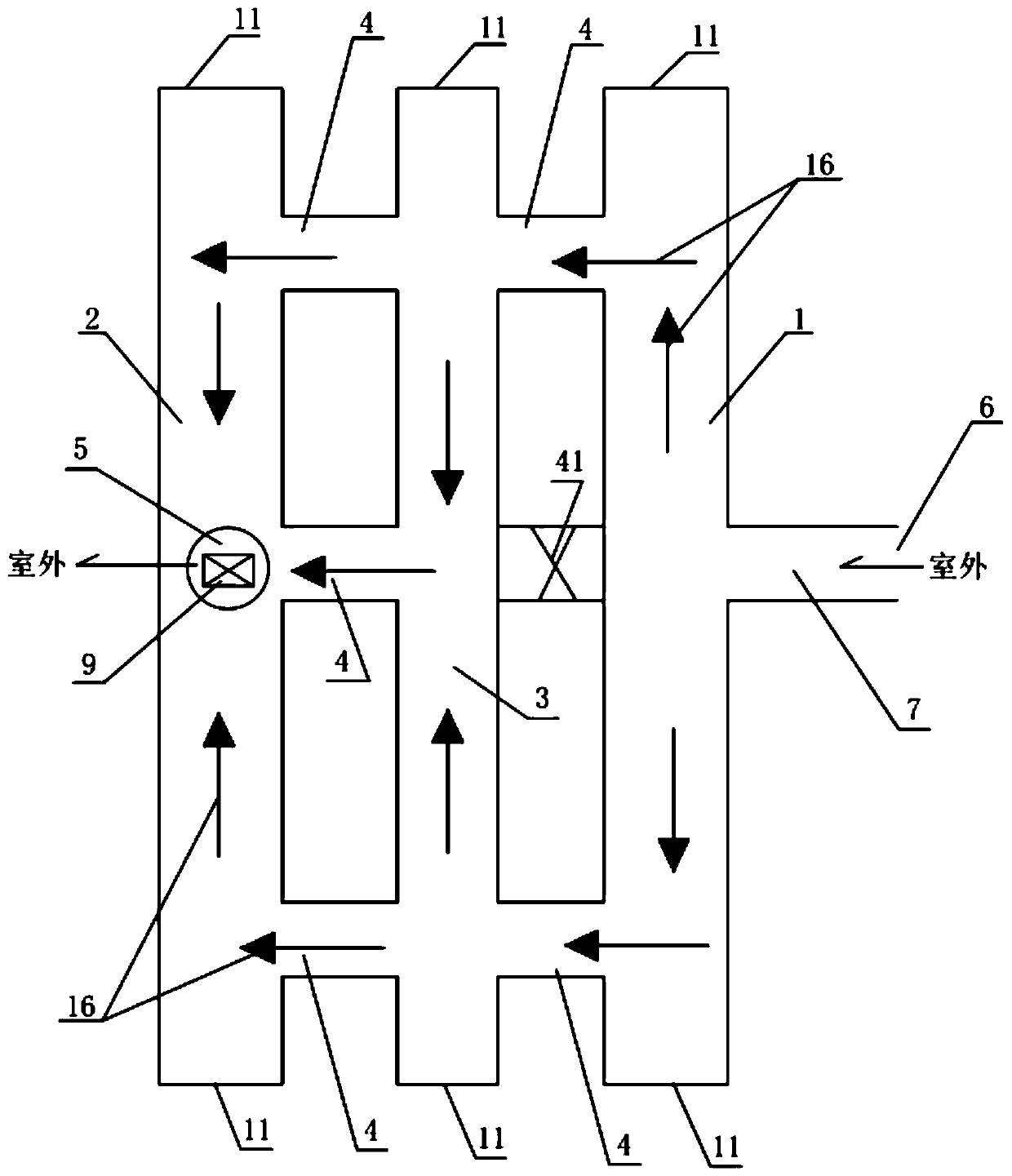

[0051] Refer to attached figure 1 And attached Figure 5 As shown, it is a schematic diagram of adopting the technical solution of the present invention under the drilling and blasting construction state.

[0052] Assume the following tunnel construction example:

[0053] The total length of a certain tunnel is 30000m.

[0054] The average elevation of the tunnel is 3500m, the atmospheric pressure is 500mm Hg, the annual average temperature is 6.5°C, and the average temperature in July is 14.6°C.

[0055] Drilling and blasting construction, the main body of the tunnel is divided into 8 sections, with a total of 16 working faces for construction, the longest section of which is 4,500m; the longest section of the tunnel in 7 plus a certain section is 7,000m.

[0056] There are two main tunnels in the main body of the tunnel, which are the first main tunnel 1 and the second main tunnel 2 respectively, and the main tunnels are excavated in parallel with the parallel pilot tunne...

Embodiment 2

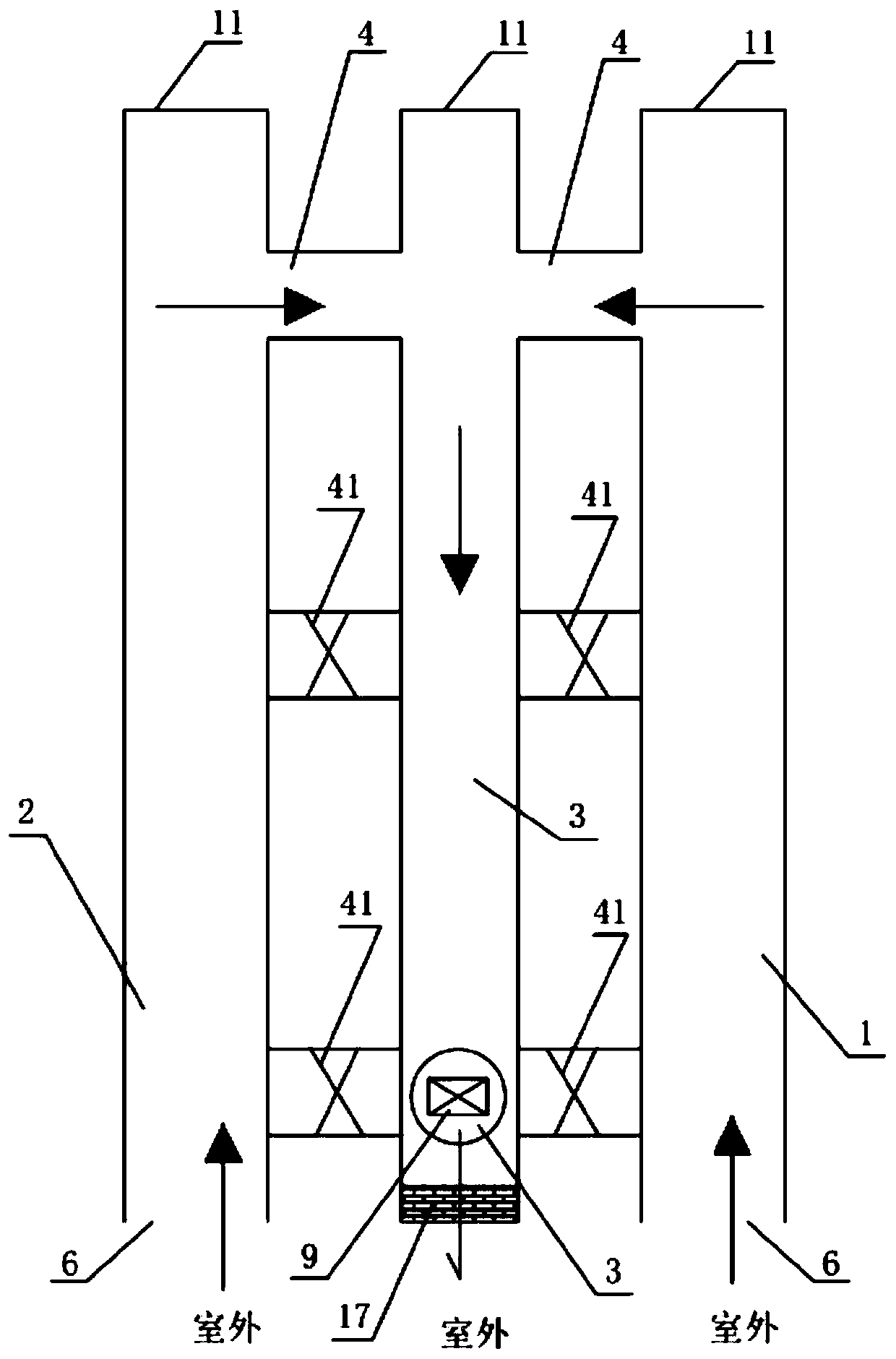

[0108] Refer to attached figure 2 And attached Figure 6 As shown, it is a schematic diagram of adopting the technical solution of the present invention under the construction state of the TBM method.

[0109] Assume the following tunnel construction example:

[0110] A tunnel is 30000m long.

[0111] The average elevation of the tunnel is 3500m, the atmospheric pressure is 500mm Hg, the annual average temperature is 6.5°C, and the average temperature in July is 14.6°C.

[0112] TBM method construction, the main tunnel and the parallel pilot tunnel are divided into 2 sections, and a total of 2 working faces are used for construction. The excavation head is 15000m long.

[0113] There are two main tunnels, namely the first main tunnel 1 and the second main tunnel 2, and the main tunnel and the parallel pilot tunnel 3 are excavated in parallel. The diameter of the main tunnel is 10m, the circumference is 31.4m, and the cross-sectional area is 80m 2 ;15000m tunnel surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Electricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com