Direct heat exchange based cooling crystallization method

A direct technology of cooling crystallization, applied in the direction of heat exchange cooling crystallization, solution crystallization, etc., can solve the problem of easily causing crystals to stick to the wall, and achieve the effect of reducing labor intensity, avoiding wall hanging, and avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

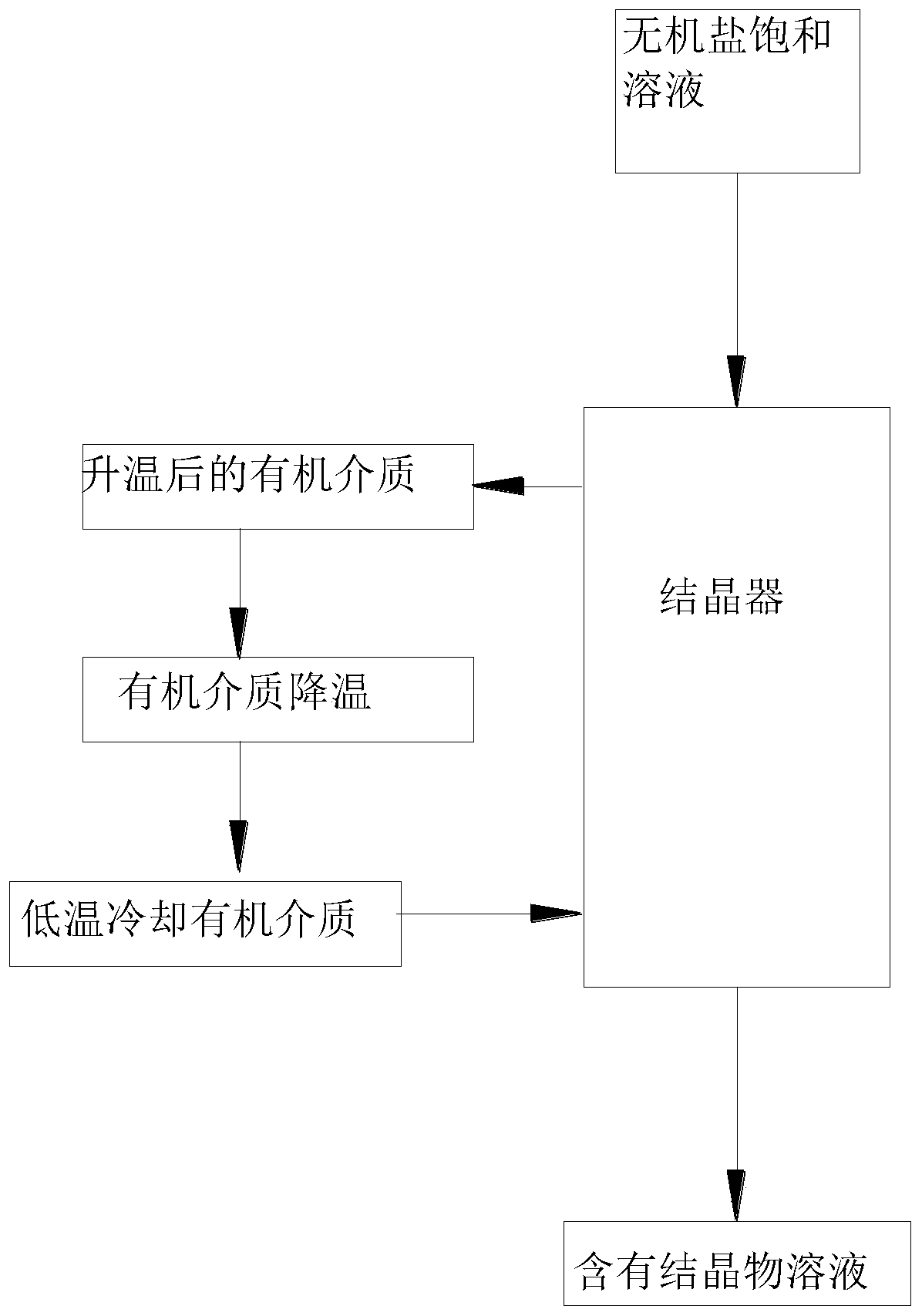

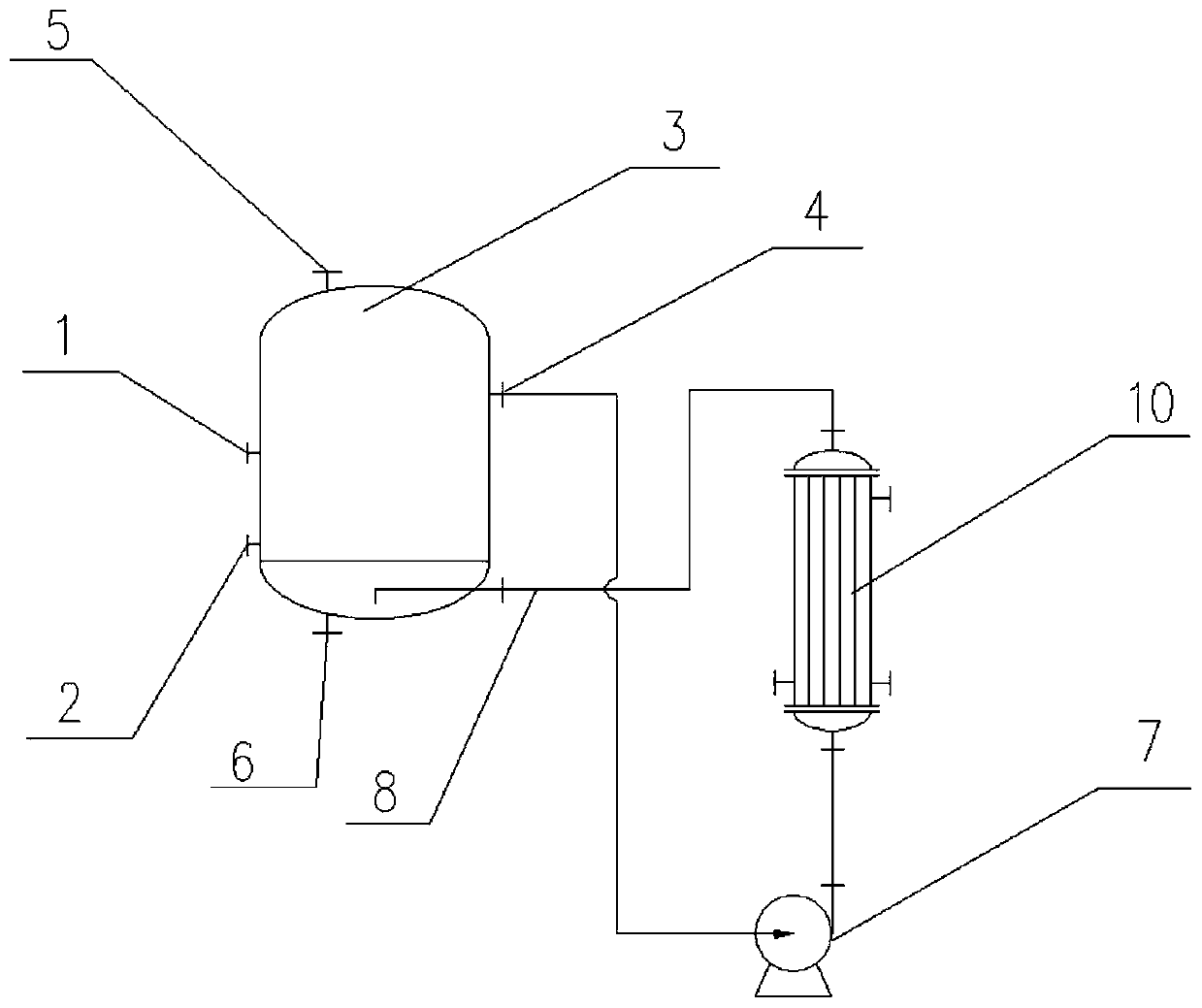

[0014] see figure 2 , the present invention comprises the following steps:

[0015] Under normal pressure, the crystallization point of sodium sulfate is 12-15 ℃, with 1m 3 At the flow rate of / h, the saturated solution containing sodium sulfate at 30-35 °C is continuously pumped into the crystallizer 3 through the interface 1; then the circulation volume is 68m 3 The low-temperature toluene of 5°C / h is passed into the bottom of the crystallizer 3 through the connecting pipe 8, and the saturated sodium sulfate solution is mixed with the low-temperature toluene of 5°C from the bottom for countercurrent mixing and heat exchange, and the toluene is heated to 8-10°C. The heat released by the crystallization process of sodium sulfate is removed, and the sodium sulfate solution is kept at about 12-15 °C, and sodium sulfate decahydrate crystals are formed at the bottom of the crystallizer 3; The pass 4 is driven into the heat exchanger 10 by the circulating pump 7. After the heat ...

Embodiment 2

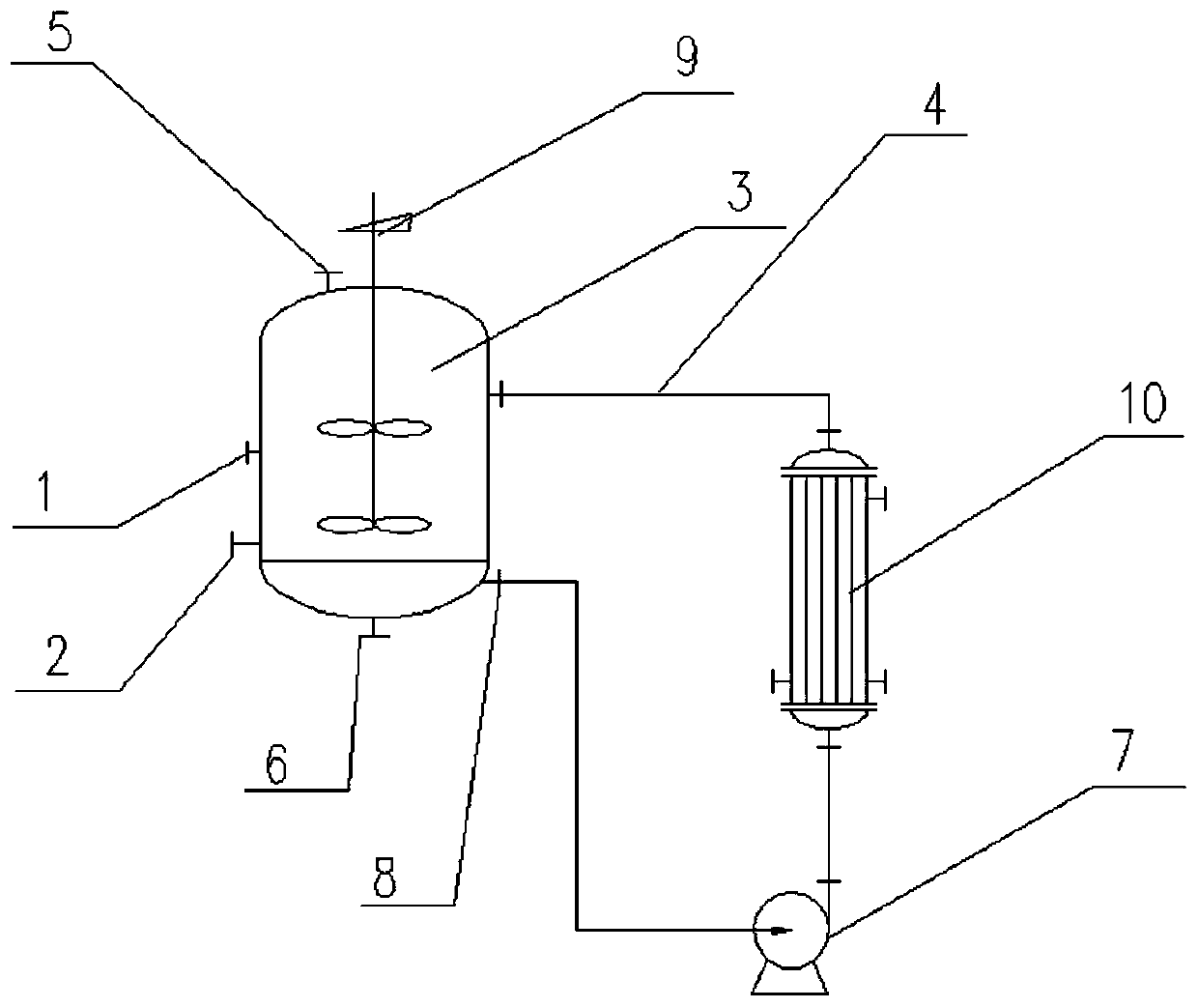

[0017] see image 3 , the present invention comprises the following steps:

[0018] Under the condition that there is no limit to the pressure, the crystallization point of sodium sulfate is 12-15 ℃, with 1m 3 At the flow rate of / h, the saturated aqueous solution containing sodium sulfate at 35°C is continuously pumped into the crystallizer 3 through the interface 2, and the crystallizer 3 is provided with a stirrer 9, so that the two liquids can be fully contacted; and the circulation volume is 75m 3 The low-temperature bromobenzene at 5°C per hour is passed into the upper part of the crystallizer 3 through the nozzle 4, and the sodium sulfate aqueous solution in the crystallizer 3 and the low-temperature bromobenzene at 5°C are mixed in countercurrent for heat exchange, and the bromobenzene takes away the crystallization of the sodium sulfate solution and releases The heat of sodium sulfate is precipitated in the crystallizer 3, and sinks into the bottom of the crystallize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com