Salted bagged non-fermentation fresh capsicum frutescens production and processing method

A processing method, millet spicy technology, is applied in the field of non-fermentation-free fresh millet spicy salted bag production and processing, which can solve the problems of insufficient solid content, long production cycle, large capital occupation of enterprises, etc., and achieve the effect of avoiding flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

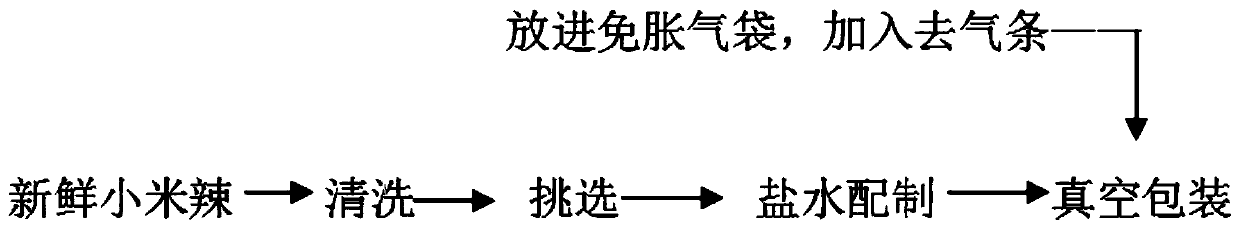

[0047] See figure 1 , A fermentation-free fresh millet spicy salted bag production and processing method, including fresh millet spicy 22%, water 65%, edible salt 15%, potassium sorbate 0.04%, glacial acetic acid 0.8%, citric acid 1%, sodium metabisulfite 0.1%, calcium chloride 0.2%, which includes the following steps:

[0048] S1. Clean the fresh millet after it is purchased to remove the foreign leaves and stalk impurities, and wash off the mud and sand;

[0049] S2. Mix edible salt, potassium sorbate, glacial acetic acid, citric acid, sodium metabisulfite, calcium chloride and water to prepare brine;

[0050] S3. Put the salt water and millet spicy obtained in S2 into a non-flatulence bag. The proportion of salt water and millet spicy is: salt water 77% and millet spicy 23%;

[0051] S4. Put the degassing strip in the place where the salt water and the hotness of millet are distinguished in the non-flatulence bag, and then vacuum seal the product.

Embodiment 2

[0053] See figure 1 , A method for producing and processing fresh millet spicy salted bags without fermentation, including fresh millet spicy 20%, water 60%, edible salt 10%, potassium sorbate 0.03%, glacial acetic acid 0.5%, citric acid 0.5%, sodium metabisulfite 0.05%, 0.1% calcium chloride, which includes the following steps:

[0054] S1. Clean the fresh millet after it is purchased to remove the foreign leaves and stalk impurities, and wash off the mud and sand;

[0055] S2. Mix edible salt, potassium sorbate, glacial acetic acid, citric acid, sodium metabisulfite, calcium chloride and water to prepare brine;

[0056] S3. Put the salt water and millet spicy obtained in S2 into a non-flatulence bag. The proportion of salt water and millet spicy is: 75% salt water and 25% millet spicy;

[0057] S4. Put the degassing strip in the place where the salt water and the hotness of millet are distinguished in the non-flatulence bag, and then vacuum seal the product.

Embodiment 3

[0059] See figure 1 , A method for producing and processing fresh millet spicy salted bags without fermentation, comprising 25% spicy fresh millet, 70% water, 20% edible salt, 0.05% potassium sorbate, 1.5% glacial acetic acid, 1.5% citric acid, sodium metabisulfite 0.15%, 0.3% calcium chloride, which includes the following steps:

[0060] S1. Clean the fresh millet after it is purchased to remove the foreign leaves and stalk impurities, and wash off the mud and sand;

[0061] S2. Mix edible salt, potassium sorbate, glacial acetic acid, citric acid, sodium metabisulfite, calcium chloride and water to prepare brine;

[0062] S3. Put the salt water and millet spicy obtained in S2 into a non-flatulence bag. The proportion of salt water and millet spicy is: salt water 80% and millet spicy 20%;

[0063] S4. Put the degassing strip in the place where the salt water and the hotness of millet are distinguished in the non-flatulence bag, and then vacuum seal the product.

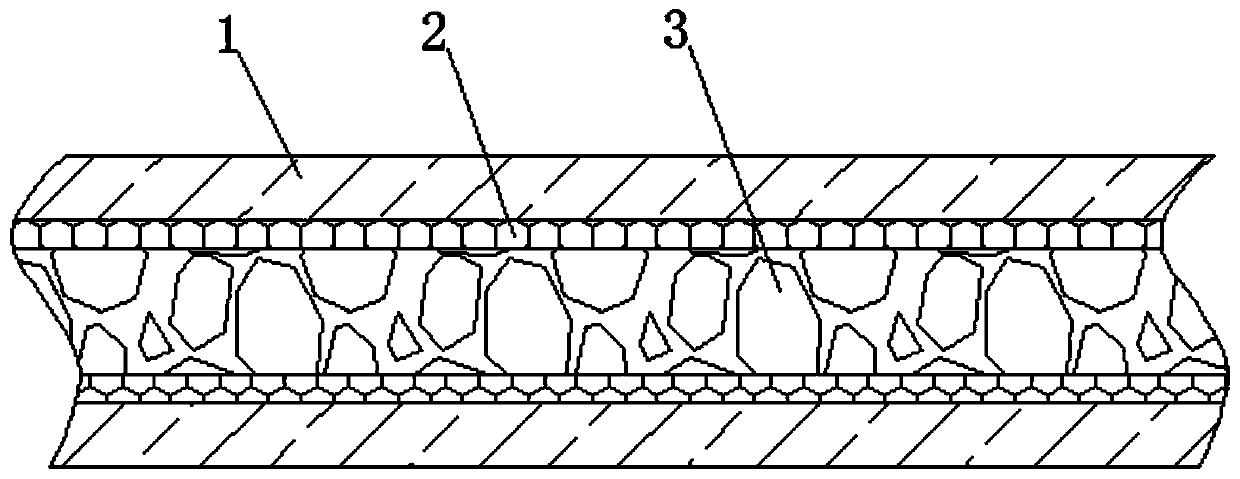

[0064] See image 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com